It is difficult to overestimate the importance of packaging materials, since not a single field of activity can do without them. And since there is a demand for products, why not create an offer? And among the entire range of packaging products, adhesive tape stands out - it is not difficult to organize a workshop, the technology is clear, and capital costs are relatively low. Therefore, when deciding which business idea to bring to life, you should definitely consider the production and sale of adhesive tape. How to open adhesive tape production in Russia? What problems must be solved on the path to success? Scotch tape is a tape made of polymer materials that has an adhesive base either on only one side or on both sides at once. And it is precisely due to the sticky base that this material has found such a wide range of applications - in everyday life and school, in construction, in the field of cargo transportation.

Our business assessment:

Starting investment – 2,000,000 rubles.

Market saturation is low.

The difficulty of starting a business is 6/10.

Despite the simplicity of the idea, certain investments in the business will undoubtedly be required. And so that the money does not end up being wasted, it is worth starting small - launching a mini factory for the production of adhesive tape. By establishing the production of small volumes of products, you can enlist the support of several large clients. And as orders increase, it is worth thinking about expanding the workshop by purchasing additional capacity.

Popular assortment and sales channels

Before starting production, it is necessary to thoroughly study the market and find out which products are most in demand in a particular market segment.

Adhesive tape is used in everyday life, in offices, in the logistics sector and in trade, which allows us to identify two main target audiences of adhesive tape consumers:

- B2C : this category consumes stationery tape, which is used for working with documents and in everyday life: transparent stationery (48mm × 10m and 12mm × 10m, thickness up to 40 microns) and double-sided with a white backing (12mm × 10m);

- B2B : this category includes logistics companies, trading and other enterprises that consume packaging tape (transparent, as well as brown and white): standard (48mm × 30m, 48mm × 50m, thickness - 40 microns) and compacted (48mm × 50m, 48mm × 66m, 75mm × 50m, 75mm × 66m, thickness – 45 or 50 microns).

Having analyzed the market and identified the most promising consumers of the products, it will be possible to purchase suitable equipment.

In the future, if necessary, you will be able to launch additional lines for the production of reinforced, automotive, aluminum, masking and other types of tape.

How to remove the tape itself

To remove masking tape without leaving marks, you must first determine the type of surface on which the tape is attached. This is explained by the fact that each material has its own characteristics that determine the degree of adhesion (or how deep the glue penetrates into the structure). The probability of traces appearing depends on this parameter.

An easy way to remove masking tape

To quickly remove paper tape from any surface, you need to wet the material with clean water and wait no more than a minute. After this, the tape must be wiped off the surface with a dry cloth.

This quick removal method is most effective when cleaning glass surfaces.

If you need to remove masking tape from furniture, it is recommended that you first read the instructions from the manufacturer. Some types of such products do not tolerate contact with water.

Removing masking tape from metal

Alcohol-containing liquids help remove dried masking tape from metal surfaces:

- alcohol (medical recommended);

- vodka;

- cognac;

- lotion.

Vodka

Cognac

Lotion

Alcohol

Beer and wine cannot remove masking tape, as these drinks contain low concentrations of alcohol and leave noticeable stains.

To remove tape from plastic or other surfaces, you need to soak a sponge or cloth in alcohol and wipe away the dirt. Before the first procedure, it is recommended to apply a small amount of liquid to an inconspicuous area. Some types of plastic do not tolerate contact with alcohol, which deforms the material or leaves yellow stains.

Heat

Masking tape adheres quite firmly to glass, wood and plastic. Therefore, if you pull the end of the tape, noticeable marks almost always remain on the surface. The latter appear even in cases where the tape is removed immediately after gluing.

A hairdryer (not a hair dryer) helps to avoid this. Using this device, you need to heat it up and then tear off the masking tape.

Prolonged heating causes deformation of plastic products.

In this regard, it is recommended to use a steamer instead of a hair dryer, after which the masking tape can be easily removed with a dry cloth.

Equipment for the production of adhesive tape

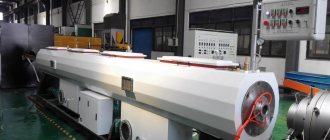

The main equipment for the production of adhesive tape are:

- automatic machine: a device that applies an adhesive layer to a special polymer film, controlling the thickness of the layer, can be equipped with flex printing, ventilation and drying;

- guillotine: a device for cutting cardboard inserts;

- machine for removing rolls.

In addition to the basic set of equipment, to speed up the work process and improve product quality, additional equipment may be required : drying for the machine (if there is no built-in one), rewinding machines, equipment for flexographic printing (for printing logos, drawings, etc.), equipment for the production of film and cardboard sleeves , packaging equipment and so on.

The most affordable equipment on the market is Chinese equipment. First of all, attention should be paid to complex production machines from Huabo , a complete set of necessary equipment which will cost approximately 30-35 thousand dollars. European machines will cost at least twice as much.

To save money, you can purchase used equipment, but you need to conduct a thorough inspection before purchasing.

Production and organizational plan

The technology for making adhesive tape includes several stages. The first is to apply an adhesive layer of appropriate thickness to the BOPP polymer film and dry it. At subsequent stages of the technological process, the finished adhesive film is rewound and cut into strips of the required sizes, which are placed on cardboard sleeves. If necessary, flexo printing is done.

The peculiarities of adhesive tape production in Russia are that almost no one works using closed-cycle technology, and ready-made jumbo rolls supplied from Asian countries - China, Taiwan, Malaysia - are used as the starting raw material. Among the main problems are the instability of product quality and the high percentage of defects in the independent production of adhesive tape.

These problems can be solved by using sufficiently high-quality and reliable equipment. In particular, it supplies full-cycle KTBS lines from China.

| Mini-factory for the production of adhesive tape | 1,300,000 rubles |

Package Included:

- a machine for the production of adhesive tape (by applying glue to the film, with strict control of the thickness and quality of application) with flexo printing;

- machine for cutting cardboard tubes;

- machine for removing rolls and loading sleeves.

To organize the production process, in addition to the main equipment, it is necessary to ensure the supply of appropriate raw materials. The following materials are used in the production of adhesive tape:

- BOPP polymer film of appropriate thickness;

- water- or oil-based glue;

- thick cardboard used to make the base of the tape (sleeve).

The specified production line has overall dimensions: 12 meters in length, 1.5 meters in width and 3.2 meters in height. Accordingly, its installation will require a room with an area of at least 50 m2 and a height of about 4 m. In addition, it is necessary to additionally allocate space for a warehouse for raw materials and materials, a warehouse for finished products, utility and auxiliary premises. The total area of the production site will be 120-150 m2.

To service the production process, nine employees will be required: 4 workers to service the production line, 2 warehouse employees (raw materials and finished products), a production supervisor, an equipment maintenance mechanic and an electrician.

Initially, you need to decide what assortment the company will produce, since the amount of equipment purchased and the required employees depends on this. To obtain large and significant profits, it is best to create a production facility where adhesive tape will be produced in various versions.

Packaging tape is considered to be quite popular and in demand; it has a significant thickness and can be produced in white or brown, and can also be completely transparent.

The main purpose of such tape is to package various goods, so it will be in demand among various manufacturing organizations.

Advice

There is also compacted packing tape, which is quite thick and is intended for packing heavy items.

The most popular is stationery tape, produced in transparent form. It is used by almost all people in everyday life, as well as in various organizations or institutions.

Additionally, you should highlight double-sided tape, which allows you to connect two surfaces.

All of the above varieties have their own advantages and characteristics, and they are all in quite high demand. Therefore, the business plan for the production of adhesive tape takes into account that for successful activities it is best to focus on the production of all types at once.

The production of adhesive tape is carried out in several stages. Initially, an adhesive composition in the required quantity is applied to a special BOPP film, which consists of polymers. After this, it is thoroughly dried under certain conditions.

The result is a finished film, which is rewound on a special machine and cut into the required sizes. The resulting rolled film must be placed on a special sleeve made of cardboard.

In some cases, the last stage involves the creation of flexo printing.

Equipment for the production of adhesive tape can be purchased separately, or you can immediately purchase a mini-factory where all of the above cycles will take place. Its cost is quite high, but as a result the production process will be high-quality and efficient.

Another machine is responsible for cutting cardboard sleeves, and the third is designed for removing finished rolls, which are then loaded into the sleeves.

The business plan for the production of adhesive tape proves that to produce high-quality and reliable material it is necessary to use only high-quality components.

Initially, you need to choose the right polymer BOPP film, which must have the required thickness. The glue must be reliable and of high quality, and you can choose a water-based or oil-based composition.

To make the bushings, you need to use only very strong cardboard, so you need to purchase the required amount in advance.

Room

To produce adhesive tape, you need to choose a production facility that can easily accommodate all the necessary equipment. Most often, a mini-factory is approximately 15 m in length, and its height even reaches 3.5 m, so the room should have fairly high ceilings, but its size does not have to be too large.

It is advisable that the rented premises be divided into several separate rooms, in one of which the components for production will be stored, in the second the process of creating adhesive tape will be carried out, and in the third the finished product will be stored for some time. You also need to provide a small utility room for workers.

Read more: 20 products that are good to sell in the fall

To open a factory producing adhesive tape, you need to spend quite a lot of money, most of which will be spent on purchasing expensive equipment. If you set up sales correctly and constantly work with corporate clients, then all costs will pay off fairly quickly.

Initial costs:

- Rent of production premises – 27,000 rubles per month

- Purchase of a production line for the production of adhesive tape – 1,500,000 rubles

- Installation of the line and its commissioning by professionals - 130,000 rubles

- Purchase of raw materials – 800,000 rubles

- Staff salary per month – 80,000 rubles

All investments pay off within 2 years, and the average net profit per month can be 80,000 rubles.

Raw materials for the production of adhesive tape

In the production of adhesive tape the following are used:

- biaxially oriented polypropylene film (BOPP) of various thicknesses;

- thick cardboard (medium quality);

- adhesive compositions (both fat- and water-based compositions are used).

Raw materials can be purchased from companies that produce them, but you can also produce them yourself - there are no particular difficulties in the production of, for example, cardboard.

Adhesive tape manufacturing technology

The production of adhesive tape in Russia has a number of features. The thing is that almost no one in our country uses closed-loop manufacturing technology. That is, enterprises are supplied with a ready-made base in the form of rolls of tape. The main problem here is the unstable quality of the finished product, since raw materials can have different compositions and properties. In general, adhesive tape production technology consists of the following stages:

- A certain amount of adhesive is applied to a special film.

- The glue dries under certain conditions.

- The finished adhesive tape is wound onto a cardboard sleeve and cut into individual rolls.

Sometimes, at the last stage, flexo printing is used to apply a logo or other design to the tape.

Scotch tape production room

Since the equipment used in the production of adhesive tape has relatively small dimensions, to organize the production of adhesive tape, a room with an area of 120-130 square meters , of which about 60 “squares” will be directly in the production area, and the same amount in the warehouses for raw materials, finished products, equipment.

Technical requirements for the premises

For normal operation of the equipment, a flat floor is required, preferably concrete.

Also, the room must be equipped with water supply and sewerage, a 380V , and ventilation.

Technical and economic parameters of the business project

Start-up investments in the project include the following costs:

- Purchase of a production line, cost - 1.3 million rubles

- The cost of installation and assembly of the production line is 150 thousand rubles.

- Other expenses (purchase of raw materials, others) – 1 million rubles.

Total capital investments amount to 2.5 million rubles.

The standard productivity of the equipment reaches 150 m2 of adhesive film per hour (in production from scratch, starting with applying glue to the film), which, with an 8-hour working day, is 1200 m2 of film per day. Provided that the equipment operates 250 days a year and at a 50% load level, the annual production volume of adhesive tape will reach 150 thousand m2 of film.

The wholesale price for transparent packaging tape with dimensions 48 mm x 50 m x 40 microns (area 0.25 m2) is about 15 rubles per unit, which is about 60 rubles per 1 m2. In this case, the annual sales revenue is 9 million rubles. The return on investment in organizing production is 12-18 months.