Occupational safety is a primary requirement

When organizing a workplace, it is important to observe several basic criteria:

- safety;

- comfort;

- environmental component;

- preventing the risk of occupational diseases;

- suppression of the possibility of an accident at work.

Workplace

This entire list relates to the concept of labor protection at the enterprise.

How to equip an office in accordance with sanitary standards and regulations

SanPiN and the Labor Code contain certain standards that must be followed when organizing a workplace for an office worker.

They can be divided into two groups:

- rules for arranging office furniture and equipment;

- requirements for microclimate, lighting, noise and vibration levels.

Failure to comply not only leads to an unpleasant conversation with inspectors, but also to low employee performance. If people have to sit in uncomfortable chairs for eight hours a day, be cold, or be in a stuffy room, they get tired quickly, get less done, and get sick more often.

In order to avoid fines and arrange an office in which all your employees will feel comfortable, you should carefully think through each workplace.

In addition to proper organization of office workspaces, it is important to take care of lighting, microclimate and noise insulation in the room.

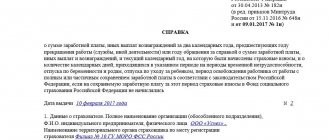

You will also have to take care of organizing a place for eating ():

- if up to ten people work in the office, the room must have an area of at least 6 m² and be equipped with a dining table;

- if there are ten to thirty workers, the area doubles;

- If the company employs more than thirty employees, it is mandatory to have a canteen.

According to the rules, the dining room must have a sink, microwave and refrigerator.

Monitoring compliance with requirements and penalties

Rospotrebnadzor monitors the implementation of norms and rules. The violating employer faces administrative liability - a fine of two to two hundred thousand rubles. Also, in accordance with the law, the company’s activities can be suspended for up to ninety days to eliminate shortcomings.

Organization of the workplace: occupational safety requirements

Requirements for the workplace are described in the Labor Code of the Russian Federation, SanPiN and local regulatory documents of the organization. Their compliance is monitored by a labor protection engineer.

Lighting standards for an office workplace

With a well-planned workspace, an employee will be able to show the best results and achieve their goals and objectives within the established time frame. In this case, the workplace must meet a number of parameters.

Noise and vibration levels in the working area

The maximum permissible threshold for noise level in the workplace is within 80 dB. To reduce noise and vibration emitted during operation, special sound-absorbing surfaces and shock-absorbing pads are used for the equipment that is the source of noise.

Substrates and foundations are also used to reduce vibrations.

Important! For certain professions, the level of noise and vibration is calculated individually. For example, for a train driver, excavator driver, boiler and pump house worker, the maximum permissible values are higher, but representatives of professions are entitled to an additional payment for this.

Indoor microclimate

An optimal microclimate must be maintained in the working area of each worker. If the work is predominantly sedentary and does not require significant physical exertion, then the recommended temperature in winter should not fall below 22-24 degrees. In summer, the optimal temperature ranges from 23-25 degrees. The air humidity in the room should not fall below 40%, but should not exceed 60%. If humidity is insufficient, the employer must provide air humidifiers.

Air speed – 0.1 m/s.

If the employer is unable to provide the specified conditions, then the duration of the working day should be reduced, and sometimes the work process may be completely suspended in accordance with Sanitary Rules and Norms 2.2.4.3359-16 dated June 21, 2016 No. 81.

Workplace standard

The Labor Code provides certain standards. According to sections of the code, a workplace is a place provided with the means required for the implementation of a production task. The state of the work space is controlled by representatives of the employer. Measures for arranging a work space imply a number of actions aimed at its configuration and planning. Compliance with regulatory requirements for packaging and planning helps to intensify the work process and increase its efficiency. Compliance with working conditions implies compliance with requirements to eliminate factors that negatively affect the employee’s condition. The list of requirements that determine employee safety and labor protection standards is set out in the relevant sections of laws, regulations, and labor protection rules. According to current legislation, employers are obliged to ensure labor safety standards.

The main provisions are:

- Providing employees with special clothing, footwear, and protective equipment (if necessary to perform work tasks);

- Creating production conditions that meet existing requirements throughout the entire workspace;

- Performing workplace recertification.

Requirements for premises for working with PCs

Requirements for a workplace in office premises

In a room in which workstations equipped with computer equipment are supposed to be located, a number of conditions must be observed. This will create the most comfortable conditions for workers:

- the distance between monitors is at least 2 meters;

- work desks are arranged in such a way that sources of natural light are located predominantly on the left. In this case, the displays must be oriented with their side surface;

- It is recommended that operators’ jobs be separated from each other if workers are engaged in heavy mental or creative work. Partition height 1.5-2 m;

PC worker

- The screen is positioned clearly at eye level. At the same time, it is recommended to equip some workplaces with special stands for monitors. The distance from the monitor to the worker’s eyes should be within 60-70 cm, but in no case less than 50 cm;

- the keyboard is located on the work surface 10-30 cm from the edge of the table;

- if the work of a computer user involves simultaneous work with reading, then special stands are provided for convenience;

- The work chair is swivel, adjustable in height and backrest tilt. The surface of the chair is semi-soft, with non-slip textiles and non-electric. It should be breathable and easy to clean;

- In some cases, workers may need a footrest.

Cleaner's area

Labor protection requirements before starting work in production

Cleaners are personnel without a strictly defined workplace. During the entire shift, they move quite actively around the given space. This type of work refers to a non-stationary workplace.

Inventory storage room

The work involves close contact with household and professional chemicals, which cannot but affect health. Therefore, these personnel must be equipped with PPE, namely gloves, an apron or overalls. When assessing working conditions, the commission pays attention to the degree of exposure to chemicals in a given work area (in an office, medical facility, warehouse). The volume of area allocated for storing equipment must be at least 2 m2.

Psychology of the workplace

When organizing production processes, it is necessary to take into account psychological aspects that affect labor productivity. You should pay attention to the arrangement of tables and equipment, the color palette of production premises, and the presence of free passages between work areas.

An interesting solution that increases production efficiency is the “5S method” developed by Japanese scientists. 5C standards determine optimal conditions for maintaining order, complying with regulations, and reducing downtime. The method is based on five steps that need to be taken when restructuring production. The main emphasis is on improving self-organization, introducing standards and improving the work process. Companies using Japanese developments note an increase in productivity, a decrease in injuries and occupational diseases, an increase in the level of corporate culture, and an improvement in the quality of work.

Company employees spend a lot of time directly at their workplaces. The attitude of workers to their responsibilities depends on the quality of their organization, which is the living space for many people. Labor efficiency and employee loyalty to the company are determined by the extent to which management cares about observing the normal working conditions of each person. With due attention of the enterprise to the organizational issues of creating a high-quality workspace, employees work with maximum efficiency and effectiveness.

office workplace

SHARE

AUTHOR

Sanitary and hygienic requirements for the workplace

Maintaining an optimal indoor microclimate is regulated in SanPiN 2.2.4.548-96. This regulatory document describes the requirements for the need to maintain optimal temperature and relative humidity, as well as the need to maintain a ventilation system that ensures a balance of fresh air inflow and outflow. At the same time, it is important to observe the noise level of the fans and regularly refuel the air conditioners.

Important! Lighting recommendations are described for individual workplaces.

Classification

Workplaces are differentiated depending on the degree of automation. In accordance with this criterion, jobs are distinguished:

- With a manual method of performing operations.

- Using power tools with external drive.

- Machine-handmade. In this case, there is a machine/mechanism that operates with the direct participation of an employee.

- Machine spaces. On them, the main activity is carried out by the installation, the control of which and auxiliary operations are performed by humans.

- Automated places. On them, key operations are carried out by machines, and auxiliary operations are fully or partially mechanized.

- Hardware places. They are equipped with special equipment on which production operations are carried out by exposing the object to electrical, physico-chemical or thermal energy.

Space for picker

To ensure a normal work process, the picker's workplace must be equipped, first of all, with the necessary equipment and mechanisms. If you are working with large-sized goods, then the employee moves on a truck, and the workplace is the entire area of the warehouse.

When weighing products is included in his job duties, he is provided with scales.

The position of a picker requires the presence of additional artificial lighting sources to ensure safety throughout the entire work process.

Picker at work

Packaging, packing, stacking of products

Special chests and tables must be used at workplaces. The dimensions of the equipment must take into account anthropometric parameters. The working surface is located at the height established in GOSTs 12.2.032 and 12.2.033. The premises where flour and flour products are packaged are equipped with a local exhaust hood. Products with a large weight are packaged on high-strength tables. These surfaces should provide containers for materials: paper, boxes, bags, and so on. For stackers-packers performing various operations, the following positions are recommended:

- for slicing gastronomic products - standing;

- for packaging, weighing - sitting and standing.

Workplaces of employees who perform operations primarily in a sitting position with limited mobility must be equipped with adjustable footrests, height, and distance from the table and comfortable seats.

Space for cashier-controller

Since the work of a cashier-controller involves a mostly sedentary position, it is important to provide employees with a comfortable chair.

Criteria:

- with a lifting and turning mechanism;

- seat height – 40-45 cm, with the possibility of individual adjustment;

- width – 42 cm;

- depth – 41 cm;

- the backrest is slightly curved to support the back.

The surface of the chair has low thermal conductivity, and the fabric allows for wet cleaning.

Additionally, employees are given footrests with the ability to adjust the angle of inclination.

The next important factor is to ensure good lighting. To protect against criminals, emergency call buttons are installed, and in some cases, protective glass is installed.

Cashier controller

Workplace lighting requirements

Office spaces for workers should be illuminated in the range of 300 to 500 lux. Some positions require individual lighting. It is better to install lamps above the work area to avoid glare.

Important! Additional lighting sources must be installed in such a way that they do not glare. It is especially important to adhere to the rules for representatives of professions that require precision actions - welder, repairman, electrician, etc.

Organization of the secretary's workplace

The secretary is the first assistant to the director of the organization. Its place should not only represent the well-being of the company, but also be as functional as possible. The reception area is divided into 2 zones: a working area and a waiting area for visitors.

Secretary's workplace

The list of necessary things for a secretary's workplace includes:

- table and chair;

- cabinet or rack for documentation;

- additional (auxiliary) table.

The furniture is arranged in such a way that the worker can quickly get from one corner of the room to another.

Next, you need to take care of the availability of a telephone, computer, copy machine, printer and other office equipment, depending on the type of activity of the company.

Important! The secretary's workplace should be located in such a way that the visitor can immediately see him and ask questions. It is important that the secretary can notice the client from afar.

Equipment and layout of workplaces.

The equipment and layout of workplaces is the basis of their organization. Elements of equipment for workplaces are main and auxiliary equipment, organizational and technological equipment.

The main equipment includes machines, machines, mechanisms, etc.

Auxiliary equipment consists of lifting devices, various conveyors, control instruments, test benches and other auxiliary equipment.

Technological equipment includes tools (cutting, measuring, auxiliary tools, dies, fixtures, etc.) and technical documentation.

The main technological and auxiliary equipment, as well as technological equipment, must correspond to the technological or production process. They are provided for in the design of the enterprise (workshop, site) and technological maps.

The standards for the required technological equipment are determined by the current technology for manufacturing the product. In this case, standard and unified technological equipment (universal prefabricated devices, etc.) is used to the maximum, which significantly speeds up and reduces the cost of its production.

Organizational equipment includes:

— devices for placing and storing technological equipment, workpieces, raw materials, materials, finished products, and waste at workplaces;

— industrial furniture;

— signaling and communication equipment, local lighting;

— equipment and workplace care items (brushes, oilers, hooks, etc.);

— fencing and safety devices;

— details of the industrial interior.

The factors influencing the choice of the necessary organizational equipment are in many cases less certain than the factors determining the choice of technological equipment. The list of organizational equipment, its quantity, and design characteristics depend on the specifics of the technology, objects and means of labor, the features of the established workplace maintenance system, as well as on sanitary and ergonomic factors and other production conditions,

Due to the complexity of establishing a list of necessary organizational equipment for workplaces, subjective decisions cannot be ruled out, leading to either a lack or excess of equipment. The lack of organizational equipment in the workplace, the imperfection of its designs cause unnecessary or irrational movements of the worker, lead to direct loss of time, underutilization of equipment and, ultimately, to a decrease in labor productivity. At the same time, excess equipment clutters workplaces, complicates the transportation of objects and means of labor, and causes unproductive financial and labor costs.

Workplace designs usually provide facilities for storing and placing fixtures, tools, workpieces, semi-finished products, finished products, industrial furniture, equipment care products, fencing and safety devices, etc. However, many workplace equipment projects do not have recommendations on communication and alarms, various equipment downtime recorders, production accounting, as well as small-scale mechanization equipment and auxiliary hand tools.

When choosing organizational equipment for the workplace, more attention should be paid to auxiliary devices and devices that form the basis for the mechanization of auxiliary work.

The simplest way to establish a list of necessary organizational equipment and the rationality of its design is to compare the actual availability of equipment with a standard project developed for a given workplace, or a labor organization map. In their absence, it is advisable to analyze the organizational equipment of the workplace.

Organizational equipment includes a large range of products, which requires a special approach to its design. Ergonomic requirements for the design of organizational equipment and equipment are basically identical, but there are also specific requirements for individual groups and types of organizational equipment.

For example, when designing tables, workbenches and other types of organizational equipment in accordance with ergonomic requirements, it is necessary to ensure the optimal height of the working surfaces, rational space for the legs, correspondence of the height of the working surfaces to the level of the arms of a sitting person bent at the elbow joints, the optimal dimensions of the working surface depending on the size and the number of products, tools, instruments, control devices, taking into account reach zones.

The design of organizational equipment and industrial furniture must ensure the correct working posture (the forward tilt angle of the body is no more than 15° with a slight bend in the lumbar spine) and the ability to change the position of the worker’s body. The height of the working surfaces of organizational equipment and the seat must correspond to the anthropometric data of the employee.

When designing racks and cabinets, it is important to consider: their optimal height dimensions depending on the method of service (manually without stands and stepladders, with their help, and also with the help of stackers); the width of the racks depending on the dimensions of containers and products, ease of installation and removal; ease of finding the necessary products, containers and the ability to record stored products.

When designing organizational equipment, attention should also be paid to compliance with sanitary and hygienic requirements: installation of suction systems for work that releases toxic gases or dust; covering seats, backs and armrests with materials of low thermal conductivity; ensuring ease and noiselessness of movement of individual elements (drawers, shelves, backs and seats of chairs, etc.); production of table tops, workbenches made of wood finished with synthetic and other materials, depending on the nature of the work performed.

An ergonomic requirement is to ensure the aesthetic perception of the designed organizational equipment. First of all, it must have a rational color design in accordance with its functional purpose, psychophysiological effect and production conditions. Painting is carried out taking into account the nature of illumination, the level of production noise, climatic conditions, the number of workers, their composition by gender and age and a number of other factors.

Providing conditions for eating

The procedure for eating at the workplace is regulated by Article 108 of the Labor Code of the Russian Federation. Organizing a space for eating is a right, but not an obligation, of the employer. However, there are cases from judicial practice in which the rights of workers were recognized as infringed. Such cases include a ban on eating in the workplace, while the enterprise itself is removed from public catering areas. In this regard, recommendations SNiP 2.09.04-87 on the organization of premises have been developed:

- if the organization employs less than 10 people, a common space of more than 6 m2 with a table is required;

- for a number of employees up to 29 people, the recommended room area is 12 m2;

- if less than 200 people are employed, the organization of a canteen and distribution center is mandatory;

- if the quantity is more than 200, the canteen is required to be supplied with food.

The dining room

In a dedicated room there are tables and chairs, microwaves, kettles and other cooking appliances. It is also recommended to consider a sink for washing dishes and hands.