Powder coating is becoming increasingly popular today. What is it? This is a modern technology designed to produce high quality decorative and protective coatings. The work uses polymer powders (hence the name “powder”). They turn into coating due to exposure to high temperatures. Because of this peculiarity of the procedure, powder coating of metal and glass is most common.

Advantages

This process has a number of positive aspects. These include:

- Cost-effective. The fact is that such paint can be reused if it does not settle when sprayed on the surface being treated. Thus, material loss is no more than 5%. By the way, this figure for conventional paints will be 8 times higher - about 40%. Also in this case there is no need for solvents.

— Ease of use. Materials for this type of work are produced completely ready-made. This guarantees consistently high quality coatings. In addition, cleaning the equipment after use is very simple, because the powder is easily removed from the parts.

- Speed. Powder coating does not require drying of products before placing them in the oven. If surfaces coated with conventional paint need to dry for quite a long time, then in this case the process is reduced significantly.

- Durability. The technology of these works involves the polymerization of a layer of elastic plastic, which has fairly high adhesion, directly on the surface that is being painted. The result is a durable coating that boasts excellent electrical insulation and anti-corrosion properties, as well as resistance to various substances.

- Environmentally friendly. As already mentioned, solvents are not used in this case, which has a beneficial effect on the environment. Waste-free production also plays a role.

- Decorative. Powder paints make it possible to obtain a surface of any shade. The palette of materials presented today includes more than 5 thousand colors and shades with various textures. If desired, you can get a glossy or matte surface, as well as granite, moire, etc.

The essence of technology

The main difference between this method is that the paint is applied dry to the object being processed. To make it clearer, let's consider this process in more detail , which can be represented in two stages:

- powder application;

- fixing the paint.

At the moment when the material is sprayed onto the surface, its smallest particles receive a charge opposite to the charge of the object being painted. As a result, they are attracted to each other due to opposite charge signs. This leads to the settling of powder particles on the surface that the master is painting.

But in this form the surface is not suitable for use. In order for the created coating to retain its color and structure, it must be fixed. To fix the powder on the surface, they use the baking method. It involves heating an object in a special chamber. Under the influence of high temperature, the dry powder melts, turning into a very durable film. A similar painting technology is often used for processing metal structures.

Powder painting as a business idea

If we take into account all the advantages of this type of work, it becomes obvious that such a business will be quite profitable. If you do not have the opportunity to immediately invest a large sum in your business, it is advisable to at least simply learn how to do powder coating with your own hands.

But it is worth considering that you will still have to spend money. First of all, you will need to take care of the availability of special equipment and a separate room. For the latter, a simple garage is quite suitable, but provided that there is enough space in it to accommodate all the tools and carry out the actual work. What equipment is needed for powder coating?

DIY powder coating of wheels.

AutoOt.ru » Do-it-yourself tuning » Do-it-yourself powder coating of wheels.

Conditions for independent work

Despite the fact that the powder coating technique is quite complex, almost anyone with the appropriate technical skills can handle this class of work. However, their independent implementation is possible only if the following conditions are met:

- the presence of a room suitable for these purposes, in which painting and drying areas can be arranged;

- purchase or rental of special equipment for powder painting (spray gun, spray gun, etc.);

- competent choice of the type of special dye used for the protective treatment of metal surfaces.

In the following sections of the article, each of the components of the preparatory process will be discussed in more detail.

Painting wheels. Useful tips. Video:

Selecting a room

There are two approaches to choosing a closed area suitable for arranging a paint booth.

- The first of them is optimally suited for country houses (dachas, for example) and involves the use of any utility room for these purposes.

- As a second option, you can consider an existing garage building on your property, converted for powder coating of wheels.

Before choosing a room convenient for carrying out work, first of all, you need to have an idea of the size of the area sufficient to organize painting and thermal drying of discs. That is why you should first decide on the dimensions and number of disks to be simultaneously placed in the processing area.

In a situation where you intend to work with small-sized piece products, an area of 3 by 3 meters within the confines of an outbuilding converted for painting should be sufficient with a margin.

If there is a significant number of products being processed, you will need a larger room with dimensions sufficient for comfortable work. In addition, powder painting technology assumes the presence of forced ventilation, which ensures that microparticles of dye and dust hazardous to human health are removed from the working area.

Important! To comply with the requirements of the technological process (in terms of high-temperature drying with the possibility of polymerization of the protective layer), the room you choose must be equipped with a heating system or a special thermal oven.

Industrial fluorescent lamps can be considered as one of the effective lighting options.

Preparation of main and auxiliary equipment

It is advisable to use industrial-grade devices (powder painting gun plus compressor unit) as a mechanism for supplying the dye to the processing site and distributing it evenly over the surface of the disks. At home, it is most convenient to rent expensive painting units for the duration of the main work.

If the specified conditions are met, known methods of drying and polymerization of painted surfaces can be implemented in the following ways:

- in the simplest case - through the use of a system of electric heaters of sufficiently high power;

- with a more professional approach - using a special oven for powder coating of processed products.

It is clear that the implementation of the second option is associated with large material and labor costs, even if you rent furnace equipment for the duration of complex work.

At the same time, painting the wheels yourself will still cost you less than if you contact a car repair shop.

As one of the options for a professional approach to arranging a furnace that ensures high-quality polymerization of the dye, the case of making it yourself can be considered. You can familiarize yourself with the procedure for assembling it and connecting it to the network in our future articles.

For those who have decided to do powder painting at home and do without a special oven design, we advise you to pay attention to the possibility of using conventional electric heaters.

That is why, even at the preparatory stage, you should worry about the quality of electrically conductive cables and carefully check the operating modes of all devices connected to them.

Please note: To the listed equipment you should add a powerful vacuum cleaner with a cyclone type nozzle, with which you can ensure maximum air purity in the painting area. The need for this household device, as a rule, arises in cases where the painting booth is not equipped with adequate ventilation.

Powder painting at home. Video:

Dye selection

In this section, we move on to describe the most critical part of the preparatory activities, which is choosing the appropriate powder coating. In it we will try to answer the following questions that interest every car enthusiast:

- How to paint car rims yourself (i.e., with your own hands)?

- What are the features of choosing a powder dye suitable for these products?

When studying these issues, first of all, let us draw your attention to the fact that the domestic market offers a large number of types, brands and colors of dyes of this class. That’s why, before you paint your car’s rims yourself, you need to decide on the choice of powder material suitable for your conditions.

It should be assumed that the following types of polymer coatings can be used to paint discs with your own hands:

- epoxy paints;

- polyester and polyurethane compounds;

- silicone dyes.

Each of the powder coating materials listed above has special, inherent qualities that determine the degree of security of the processed product. Thus, epoxy compositions are characterized by increased resistance to alkaline and acidic environments, and polyester paints have excellent anti-corrosion properties.

The advantages of polyurethane coatings include increased resistance to solvents and abrasives.

Important! You can choose a specific type of dye only after familiarizing yourself with the features of each sample, which determine the possibility of using it for self-application at home.

The most common and well-known names of powder protective coatings include such well-known domestic and foreign samples as “Pulverit”, P-EP 45, “Infralit”, “Bichon”, “Beckers”, “Radar”, “Inver”, TFK and Flycoat.

Using products from these manufacturers, every car enthusiast can easily cope with all the tasks assigned to him, including selecting the appropriate color scheme (in the RAL standard) and the surface texture of the wheels.

Using some of these dyes, you can change the structure of the coating, which is represented by a number of popular types (shagreen, antique, moire and the like).

Additional information: powder coating of wheels requires the mandatory use of special work clothing and respiratory protection.

Powder coating of wheels

Once all the conditions for independent restoration work have been met, you can proceed to direct processing of the disks, carried out in accordance with the requirements of current regulations.

Before you paint car rims with your own hands, you need to carefully familiarize yourself with the technological features of these procedures. According to accepted standards, the order of their implementation is as follows:

1. Before starting painting work, the surfaces of the disks are thoroughly cleaned of corrosion, old paint residues, as well as traces of dirt and oil stains using a metal brush, sandpaper and solvent (abrasive and chemical treatment, including degreasing).

If it is impossible to remove rust embedded in the metal, you will have to organize its etching, carried out using solutions of various acids (sulfuric, phosphoric, hydrochloric or nitric).

2. At the next stage of surface preparation, it is treated with chromium, iron or manganese phosphate, which helps improve the adhesion of the metal to the protective primer coating. Upon completion of the phosphating process, the discs prepared for painting are thoroughly washed with warm water and then dried.

3. Next, they proceed to applying a special primer coating to the surface, which ensures improved anti-corrosion properties and adhesion to the sprayed dye. To protect cast wheels, epoxy (epoxy-zinc) primers are usually used.

4. Upon completion of the preparatory work, the discs are placed in a special painting area or box with limited scattering of microparticles sprayed by the gun (in this case, the body of the processed products is reliably grounded).

5. The powder mixture is applied to the surfaces to be treated using the method of electrostatic spraying, according to which charged particles, when scattered, are attracted by a grounded metal disk.

Upon completion of paint application, the discs are subjected to special heat treatment (so-called “polymerization”), which ensures the melting of the protective layer and its reliable adhesion to the previously prepared coating.

For this purpose, they are either placed in a home-made oven or subjected to high-temperature treatment using powerful electric heaters.

Conclusion

In the final part of this article, we will try to once again draw your attention to the importance of preparatory procedures associated with arranging a room suitable for work and purchasing all the necessary equipment and powder materials.

Despite the apparent complexity of the technological process we have described, its implementation is quite within the capabilities of an attentive and careful performer. Provided you follow the requirements and recommendations of this article and in the absence of haste, you will be able to overcome the difficulties that arise during the work and successfully cope with all the tasks.

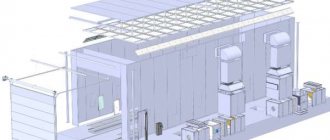

Camera

Carrying out the work will be impossible without a special camera. This is where most of the entire process is performed. The powder coating chamber is needed for air purification (recovery process), in addition, it is due to it that the material can be reused. Here, paint that does not reach the surface being treated is sent to filters and then discarded.

Such equipment can have different sizes. Which one to choose should be decided individually in each case, having previously determined which products you plan to work with.

Powder coating technology for metal products

Organizing a powder coating business for metal products is one of the simplest activities that a novice entrepreneur can handle without much hassle. He will only need to rent a room (or refurbish his own), purchase equipment, and conduct an advertising campaign in accordance with the task.

To open a paint shop, it is worth conducting an analysis of the demand for the service, namely, determining which companies need it. The peculiarity of this business is to provide services specifically to large manufacturers, since there are very few private clients.

Stove and gun

You will also need a reflow oven. This is a prefabricated structure consisting of panels (their thickness is 100 mm). Thermal insulation material – basalt fiber. If you are just trying your hand at this type of work, it is not necessary to immediately buy a special oven. For this purpose, it is quite possible to use a conventional oven. However, to build a business, it is still recommended to purchase professional equipment.

Powder coating technology also requires a spray gun that allows the use of compressed air. You can also use a compressor as this. If you choose the latter, please note that it must have a high-pressure filter installed.

Recuperator and transport system

The remaining powder paint is collected using a recuperator. Instead, at first you can use a cyclone-type vacuum cleaner. In this case, you need to first check the power of the electrical network in the room and make sure that there is grounding.

If you plan to work with large items, then you should also consider purchasing a transport system. In it, the workpieces are moved on special trolleys that move on rails. This is how a powder coating line is built. Such equipment improves the productivity of the process, ensuring its continuity.

Preparatory stage: cleaning, degreasing

We can say that this stage is the most labor-intensive. And it depends on it how high-quality and durable the coating will be. In the process of preparing the surface, it is necessary to remove all contaminants from it and degrease it.

Cleaning is carried out using mechanical or chemical methods. The first option involves using steel brushes or a grinding disc. You can also grind in with a clean cloth, after moistening it in a solvent.

The second cleaning option involves the use of alkaline, neutral or acidic composition, as well as solvents. Their choice depends on how dirty the surface is, what material the product is made of, what type it is and what dimensions it has.

Criterias of choice

One of the key issues that the master must decide is the choice of a specific powder paint for processing the object. This is very important, since the quality of the product’s coating directly depends on the material. The stores offer a large number of different types of dry paints with different characteristics.

A good paint must satisfy certain functional requirements . The main ones are:

- Mechanical resistance. The material must be wear-resistant, durable, and resistant to scratches, impacts and abrasion.

- Temperature resistance. The paint is required to be resistant to high temperatures, as well as heating, both periodic and constant.

- Electrical insulating properties. Most polymer coatings are dielectrics, which makes it possible to use them to isolate finished products from electricity.

- Chemical resistance. The selected material must tolerate interaction well with oils, fats, detergents, gasoline and other substances with which the coating will come into contact during operation.

- Rust resistant. When choosing paint, it is important that it is resistant to chemicals and moisture - the main causes of corrosion.

Additionally, the paint may differ in decorative properties:

- Smooth coatings. Available in various color options.

- Textural. May include certain special effects, for example, orange peel, wrinkling, etc.

- Transparent. Used to protect metal, plumbing and other products.

- Tinted. They allow you to highlight metal or a substrate for various types of materials - metal, bronze, etc.

- Gloss level. Depending on this, there are semi-gloss and glossy coatings, as well as coatings with varying degrees of gloss - from dull to high.

Phosphating and Chromating

Next, a conversion sublayer can be applied to the product, which will prevent moisture and dirt from getting under the coating. Phosphating and chromating procedures provide better adhesion and protect the surface from rust. For this purpose, iron phosphate (for steel), zinc (when working with galvanic cells), chromium (for aluminum) or manganese and chromic anhydride are most often used.

Then you will need to remove the oxides, which is done using abrasive and chemical cleaning. The first is produced using abrasive particles (shot, sand), nut shells. These substances are supplied with compressed air at a fairly high speed. As a result, the particles “crash” into the surface of the product and bounce off it along with the contaminants.

Pickling (chemical cleaning) is the removal of various contaminants using special etching solutions, the main components of which are sulfuric, hydrochloric, nitric, phosphoric acid or caustic soda. This method is considered more productive, however, after such treatment, the product must be rinsed from solutions.

paints and varnishes

101 votes

+

Vote for!

—

Vote against!

Powder coatings are applied to products mainly by automatic or manual sprayers, and then undergo polymerization in a special oven and at a precisely specified temperature. Since the price of powder coating in specialized salons is quite high, today we will try to carry out this procedure at home. But before that, you need to first worry about choosing the room where you will do the work, buy the necessary equipment and carefully prepare the surface. So here we go!

Equipment selection

For a complete and high-quality powder painting process, you need to choose the right room where the procedure will take place. For such purposes, a regular garage is suitable, with enough free space for work.

So, work on painting the surface with powder paint should begin with preparing equipment for powder painting of metal. The main equipment is a special camera. This is where the bulk of the process takes place. The characteristics of such a furnace depend on what materials and products will be processed.

The painting chamber includes the chamber itself, where powder paint is sprayed, and a melting furnace. If you do not plan to paint constantly, there is no need to buy a professional oven; you can use a regular oven for this work.

In addition to the camera, the powder painting process requires an electrostatic spray gun that allows you to connect compressed air. A compressor can also be used for this purpose. When purchasing a compressor, you must pay attention to the presence of a high-pressure filter in the package.

Before powder painting, care should be taken to ensure that all technological processes are carried out in a room with good lighting. You can use fluorescent lamps for this, this is necessary so that the paint does not stick to the hot surface of the lamp. And of course, during the painting procedure there must be excellent ventilation in the building, without which the whole process turns into harmful to the body.

You can use a recuperator to collect leftover powder paint. But at the initial stage, an ordinary cyclone-type vacuum cleaner is also suitable, since a “traditional” vacuum cleaner will most likely clog. In order for the procedure to proceed smoothly and without failures, it is recommended to take care in advance of a powerful electrical network with grounding.

When processing large-sized products or large volumes, it is customary to use a special transport system. This allows the painted parts to move easily throughout the powder coating process between stages.

The operating principle of the transport system lies in the fact that the parts to be painted are transported on trolleys or a special suspension that move along rails. Such a transport system allows for continuous painting, which, in turn, significantly increases the productivity of the entire work process.

Surface pre-treatment

Product preparation is the longest and most labor-intensive process, which is often not given much attention, but the quality, elasticity and durability of the coating depend on it. Pre-treatment of the surface for painting involves removing any contaminants, degreasing the part and phosphating to increase adhesion, as well as protecting the metal from corrosion.

Clean the surface to be treated chemically or mechanically. For mechanical cleaning, steel brushes or a grinding disc are used; a grinding procedure with a clean cloth soaked in a solvent is possible. As for chemical processing, it is carried out using an alkaline, acidic or neutral composition and solvents, which are usually selected depending on the level of contamination, material, type and overall dimensions of the surface being treated.

Applying a conversion sublayer, as shown in the powder coating video, prevents moisture and various contaminants from getting under the formed coating, which provoke peeling and future destruction of the coating. The procedure of phosphating the surface with the application of inorganic paint allows you to increase adhesion - the adhesion of paint to the surface by 2-3 times and protect it from rust formation.

When removing oxide (rust, scale and oxide film), abrasive (shot blasting, shot blasting, mechanical methods) and chemical cleaning (etching) are very effective. Abrasive cleaning is carried out using small particles (sand, shot), steel and cast iron granules, nut shells, which are fed at high speed to the surface of the product by centrifugal force or compressed air streams. These particles are capable of breaking off pieces of metal with rust, scale or other contaminants, which significantly increases the adhesion of the coating.

Pickling is the removal of rust, oxides and other contaminants using solutions based on nitric, hydrochloric, phosphoric and sulfuric acid or caustic soda. They contain inhibitors that slow down the dissolution of the cleaned surface. The advantages of chemical cleaning over abrasive cleaning are high productivity and ease of use. But after such a procedure, it is recommended to rinse the cleaned surface from solutions, which requires additional use of a cleaning agent and increases the cost of powder painting.

The final stage of surface preparation is passivation - treatment of the body with chromium and sodium nitrate compounds. Passivation is carried out in order to prevent secondary corrosion at any stage of surface preparation - after phosphating, degreasing or chromate plating. Having completed the process of rinsing and drying the part in the oven, we can assume that the surface is ready for applying paint in powder form.

Powder paint application

After completing the pre-treatment, you can place the object to be painted in the spray chamber, where special powder paint will be applied to it. The main purpose of such a box is to catch powder particles that have not had time to settle on the part being painted, to dispose of the paint composition, and to prevent it from entering the room. The painting chamber inside has a filter system, cleaning equipment (vibrating screens, hoppers) and a suction system.

There are through and dead-end types of boxes. It is customary to paint products that are small in size in dead-end painting booths, but large-sized items are painted in long ones. There are also known automatic models for powder painting of metal, where the powder coating is applied to the surface in a matter of seconds using manipulator guns.

The most common method of applying powder paint is electrostatic spraying - applying an electrostatically charged substance to a grounded part using a pneumatic sprayer, which is called a gun, spray gun or applicator.

Formation of coating

When you have already applied paint to the product, it should be sent to the next stage - the formation of the coating, which includes melting the paint layer, forming a film on the coating, curing and cooling the product.

The reflow process is carried out in a special chamber or oven. There are many types of these polymerization chambers, depending on the specifics of production, their design may vary. In simple terms, such an oven is a kind of drying cabinet that has electronic “stuffing”.

Using the control unit, it is possible to control the temperature of the chamber and the dyeing period, and set automatic shutdown at the end of the dyeing process. The energy source for the polymerization chamber is electricity, fuel oil or natural gas. There are vertical and horizontal, dead-end and pass-through, single- and multi-pass painting ovens.

The procedure of melting and polymerization, according to powder painting technology, is carried out at a temperature of approximately 150-220 degrees Celsius for 15-30 minutes, as a result, a film is formed, that is, polymerization of the powder paint occurs. The main requirement for a polymerization chamber is to constantly maintain a certain temperature so that the product being painted is heated evenly.

The required mode for creating the coating is selected taking into account the product, the type of powder paint and the painting oven. At the end of the polymerization procedure, the painted product is cooled in the open air; after cooling, you can consider that the coating is ready.

Paint baking process

After powder painting the surface with your own hands, the product must be placed in the oven, which must first be preheated to approximately 210 degrees Celsius. The paint must be “baked” for approximately a quarter of an hour. However, it is not at all prohibited to open the oven to check the condition of the paint. After the paint has completely dried, carefully remove the metal from the oven and wait until it cools.

When powder coating, remember that heated metal is softer (and very hot), so find a secluded place for it so as not to accidentally touch it and get burned. Once the metal has cooled, you can admire your work! Powder painting is now complete.

Applying paint

What is powder coating technology itself? The prepared product must be placed in the chamber. Here the powder (paint) will be applied to it. If you have a dead-end box, then only small parts can be painted in it. Large products can only be processed in long chambers.

The most commonly used method for applying paint is electrostatic spraying. In this case, powder coating guns are used. These tools are also called sprayers or applicators. This device is a pneumatic sprayer that applies an electrostatically charged substance to a previously grounded part.

Formation of coating

Let's move on to the next stage of work. The paint is applied, now you need to form the coating. First of all, the product is sent to the oven for polymerization. Such chambers can be different: vertical, horizontal, again, dead-end or pass-through, single-pass and multi-pass.

The mentioned powder coating equipment ensures heating of the surface to a certain temperature - 150-220 °C. The treatment lasts about half an hour, resulting in the formation of a film. At this stage, it is important that the part is heated evenly, which is only possible if the temperature in the chamber is stable.

Which mode to choose for processing a particular part depends on the part itself, the type of paint and equipment. After polymerization is completed, the product must be cooled in air. That's it, job done.

Furnace test

Before the test, the oven itself must be warmed up several times. This way the metal frame will take the desired shape. This will also help identify potential shortcomings and defects.

When the door to a heated chamber is opened, the temperature drops significantly. For this reason, parts must be placed into the chamber quickly and without damaging its coating. After these tests, you can work with the debut painted part. It is important to consider here that the type of coating being processed requires different temperatures for the polymerization process.

- Priming requires 170˚C.

- For paint – 190˚C.

- For varnish coating – 200˚C.

Interval required for each layer to harden: 15–60 minutes. After this, the oven itself should reduce the speed to 100 degrees. Only in this situation can you get the part. It is already completely cooled down at room conditions.

These are the main principles of creating an oven for polymerizing powder paint. How difficult this task is depends on your technical skill and discipline, as well as strict adherence to important calculations and painting techniques.

Areas of application

As you can see, powder coating is a rather labor-intensive job that requires certain investments. What products are exposed to it? The painting method under consideration is ideal for processing aluminum or forged products, as well as galvanized surfaces.

Powder paints are finding more and more “fans” these days. Now they are used in instrument making, construction, automotive industry, as well as in other areas. They are used to paint medical equipment, roofing materials, household appliances, objects made of ceramics, plaster and glass, and furniture. Powder coating of wheels is becoming increasingly popular among car enthusiasts.

Business organization

These works in specialized centers today are quite expensive. If you want to try yourself in this business, then if you have financial resources, you can start. Of course, not everyone can afford a powder coating line (automated system), but thanks to our recommendations, you will be able to replace some elements with other tools at first.

Start with small items. These can be plaster figurines, ceramic dishes and much more. Try painting something in your home first (start with something you don't mind ruining). Gradually you will develop the necessary skills and dexterity, then you will be able to accept orders from friends. However, you shouldn’t expect much income if you rely only on one-time orders from individuals.

The best case scenario involves the presence of large start-up capital. In this case, you can immediately purchase the necessary equipment and hire workers. Clients should be sought among enterprises engaged in the production of metal products. Only the presence of such customers will allow your business to exist and develop.