* The calculations use average data for Russia

500,000 ₽ Minimum starting capital

250-300 thousand rubles. Profit per season

15-20% Profitability

Shoe manufacturing can be a profitable business. But only if you are well acquainted with this industry, know all the nuances of sewing shoes, choosing equipment and materials, and, most importantly, you have an original idea that will allow your products to stand out from the competition.

The situation with the shoe business in our country is currently not the best. The profitability of shoe production is about 15-20%. At the same time, the volume of imported products on the Russian market is estimated at 90%. And most of it is cheap shoes made in China. It is characterized by low quality and at the same time low prices and a wide range.

Overview of the footwear market in Russia

The situation in the footwear market worsened in 2010, when a single duty of 10% was established on all types of footwear imported into our country. Before January 1, 2010, shoes were divided into several types. Most imported footwear products made from leatherette were taxed at a rate of 15%. The duty reduction caused great concern and made life difficult for domestic manufacturers, who could still successfully compete with Chinese companies in this segment of inexpensive faux leather shoes.

As a result of such innovations, in two years the number of Russian factories that sew shoes in our country has decreased by more than three times. Another serious problem that domestic shoemakers have to solve is “gray” imports. It accounts for about half the volume of imported products sold on the Russian market. The closure of markets, proposed by the authorities as a solution to the problem of “gray” products, did not save producers, since points selling illegally imported shoes simply opened in other places.

However, despite all these unfavorable factors, the shoe manufacturing business in our country can be profitable and promising, according to experts, including the manufacturers themselves. Russian production provides about 15% of domestic demand and up to 20% in the men's footwear segment. A profitability rate of 15% can also hardly be called low. The largest grocery chains are known to operate with margins three times lower. The main conditions for the success of a Russian shoe factory are the use of the most modern technologies and high-quality equipment, as well as competent positioning and promotion. True, both require considerable investments.

There are three largest segments in the footwear market:

- women's,

- men's,

- children's products.

In addition, special (for example, orthopedic) and work shoes occupy a special place. The situation is best among manufacturers of children's shoes, since they are purchased much more often than shoes for adults. Imported high-quality products turned out to be too expensive for many consumers, and Chinese shoes, according to popular belief, are characterized by extremely low quality and a short service life. Therefore, most parents prefer to buy shoes from domestic factories for their children. Another advantage of the latter is that they still produce their products according to Soviet GOST standards, which regulate both medical standards and consumer properties of the product.

Many companies prefer not to open their own production facilities in our country, but to place orders at Chinese factories. Another problem hindering the development of Russian shoe production is the lack of high-quality domestic raw materials for the manufacture of shoes. The construction of one large tannery requires large investments - about $1 billion. Moreover, the payback period for such a large-scale project will be, according to preliminary estimates, 8-10 years. With the production of other components of shoes - lasts, accessories and soles - the situation is much better, but this does not save the situation. The cost of Chinese footwear products in the low price segment still remains lower than domestic ones, since almost half of the shoes produced in our country consist of imported materials.

Profitability of the shoe manufacturing business

Many small regional enterprises that manufacture shoes operate semi-legally. They place their equipment on an area of up to 50 square meters. meters in closed areas (for example, in a private house) and do not pay taxes. The main sales channel for such “gray” shoe manufacturers is retail chains and private customers, whom manufacturers seek through the Internet and specialized exhibitions. Despite all of the above problems and difficulties, which significantly complicate the lives of Russian shoe manufacturers, the business of manufacturing such products can become successful even with small investments. The main thing is to correctly determine your target audience, price segment, develop an interesting design and pay great attention to quality. Most Russian manufacturers work in narrow niches. For large-scale production, serial production is of no small importance, so the majority of the assortment of such an enterprise consists of sports and casual men's and women's shoes of the low and medium price segment. The production of, for example, high-heeled women's fashion shoes requires serious investment. Such production cannot be unified, therefore, from the point of view of entrepreneurs, it is unprofitable and takes a long time to pay off.

New companies that are just planning to engage in shoe production follow two paths: they either open a full-fledged production (in their own factory, which is very rare, or place orders at Chinese enterprises), or they work in an atelier format, fulfilling private orders or producing exclusive expensive shoes. models.

It's better to be a pro at one thing

Perhaps we will not reveal a secret to you by saying that the footwear market requires competence and systematic monitoring of both new trends and design innovations. This area is very vast, so you shouldn’t spread yourself thin in it. If you focus your young business on one segment and become a kind of “guru” in it, then success will certainly await you, and no competitors will be able to interfere with this. So, let's go over the main parameters of this interesting business from the point of view of investing financial resources.

We consult and then we do it

First of all, you will need to register your business. The choice of ownership form depends on the scale of the business. You can discuss this issue in more detail with a lawyer or an experienced accountant. The latter, by the way, can help you choose a form of ownership in which you can pay the minimum amount of taxes.

After registering the company, it’s time to start choosing the location where your retail outlet will be located. It is very important that, on the one hand, it be a crowded place, closer to the city center, in order to ensure maximum profitability of the shoe store, and on the other hand, it is important that the rent is within a reasonable range. Optimal operating hours are from 10.00 to 20.00.

As for the assortment, it is better if it is designed for buyers with ordinary incomes and people with average capabilities. This is the most profitable niche. It is important that a wide assortment includes a variety of men's, children's and women's shoes. The buyer must be given the opportunity to choose between different price categories.

Documents for starting a business

The list of required documents for registering a business depends on how large it will be. If at the initial stage a small production is planned, then it is enough to open an individual entrepreneur. You can choose a simplified taxation option with 6% of total revenue or 15% of net income (after deducting expenses). To choose the most profitable option, it is better to consult a lawyer or accountant.

You will also need to select the required OKVED code. To do this, you need to decide on the type of shoes that will be produced. If in the future you want to change or add to the assortment, it is optimal to choose code 15.20. It includes the production of almost all types of shoes. Before choosing, read in detail the list of all options to which it applies.

So how to start a shoe production?

Once you have determined the approximate location for your retail outlet, it is important to resolve a number of serious issues. So, for example, you need to understand whether your store will be a kind of pavilion at a clothing market, or would you prefer it to be located in a large shopping center? Or maybe it will be a separate boutique? Depending on the decision made, it is necessary to prepare financial resources.

It would be incorrect to give a specific number here, since each city has its own prices for renting premises, retail spaces and individual boutiques. Moreover, each of the possible solutions has its pros and cons.

Cut the leather

Naturally, leather for handmade shoes is cut only by hand. If we are talking about tailoring shoes to order, then individual, specially created patterns are used to cut out pieces of leather. For finished shoes, standard patterns are used, usually made of plexiglass or other modern material.

Shoemakers use a clicker knife to cut hides, and this procedure itself is called clicking.

Cutting leather for shoes

The worker performing it faces a difficult task: he needs to use the skin as rationally as possible, while rejecting all areas with defects. In the case of very expensive custom-made shoes, only the best parts of the hide are used, and many hides are discarded at the procurement stage.

From market to boutique

However, if you ask how to open a shoe production with the least investment (after all, at the beginning of any business, as a rule, there is no significant capital), then we can advise you to rent a small boutique in a shopping center. As a last resort, you can start with a regular clothing market. The most important thing in this business is to have a good, high-quality product at a price that is favorable to you (or better yet, produce it yourself in order to control its cost yourself).

Thanks to this, you will quickly acquire a circle of retail and wholesale clients, who will bring you the amount of money you need to expand your business. If you do not have the equipment to produce shoes and cannot create your own product, then you will have to solve the problem with suppliers. Fortunately, there are no problems with their availability. The only question that arises is their reliability and the quality of the shoes provided.

The market is, in fact, literally flooded with various offers for wholesale delivery of these products, both from domestic and foreign manufacturers. There is a wide range of Chinese, Turkish and Italian shoes. It pleasantly amazes with the abundance of materials from which it is made, as well as the variety of colors and types. In foreign countries, factories (for the most part) are well equipped and have excellent equipment for the production of shoes. That's why their products are truly beautiful.

Organization of shoe production step by step

Having decided to open a shoe production workshop, the entrepreneur decides on the direction of this activity - the types of future products, as well as its features. Next, a business plan for shoe production is drawn up, containing all the necessary information about the project and financial calculations.

Registration

For the official activities of an enterprise, its registration is necessary. If you plan to organize a small production, then the individual entrepreneur form is quite suitable for it. Opening a factory with large production capacity will require registering an LLC, this will allow the sale of finished products in large quantities.

Registration of individual entrepreneur status is carried out as follows:

- preparation of a package of documents, including a passport, TIN, registration application, receipt of payment of state duty in the amount of 800 rubles;

- handling prepared documents to the tax authority;

- choice of taxation system;

- indication in documents of OKVED codes corresponding to the production of footwear;

- receiving a registration certificate within 5 working days.

Registration of LLC status occurs in the same sequence; you will need the following documents:

- statement;

- founder's passport;

- decision to establish a legal entity;

- charter of the company;

- information about the authorized capital;

- a receipt confirming payment of the state duty.

It is recommended to choose the simplified tax system with a rate of 15% of profit as the tax burden.

When preparing documents, indicate OKVED code 15.20 (Manufacture of footwear for various purposes).

Search for premises for a workshop

When choosing production areas, the planned scale of activity is taken into account. For a small enterprise, 3–4 rooms equipped with a standard list of communications will be enough. A factory producing significant volumes will need an area of at least 7,000 m2, geographically located in an industrial zone near transport interchanges.

Before signing a lease agreement, you need to make sure that communications are in good working order: electricity, heating, hot and cold water supply.

It is important that the power grid is for industrial purposes, as some production machines consume up to 50 kW.

Purchase of equipment

Before purchasing a production line, you need to decide on the range of shoes and the direction of production. Based on this, a list of required pieces of equipment is compiled. In order to save start-up capital, it is recommended to purchase used machines and gradually replace them with new ones as the company grows.

Search for suppliers of raw materials

To make high-quality shoes you will need genuine leather, which is the main material in this production. Purchases do not have to be made from foreign companies, since customs and delivery costs will significantly increase the cost of products. In the Russian Federation there are many companies specializing in the sale of raw materials for the production of footwear.

Compilation of product range

In the early stages of opening a project, the entrepreneur decides on the types of shoes that he will produce and the price category. It is best to focus on the population with average income. It is recommended to include male and female models for all age categories in the production plan.

Staff

When hiring employees, planned production volumes are taken into account. For a large enterprise operating in two shifts, at least 200 people will be needed. A small business will only need a few employees:

- designer who develops models;

- operator servicing equipment;

- a tailor who creates patterns and sews shoes;

- manager dealing with organizational issues;

- Sales Manager;

- accountant;

- premises cleaner.

Who and how much?

When deciding which supplier to give preference to, it is important, first of all, to be guided by the desires of your target audience. It’s also a good idea to take into account the climatic features of your region. However, no matter where the shoes are brought from, we do not advise you to make large markups. Just because you have just opened, consumers should know about you and love you.

The quality of shoes should be commensurate with the price. Always try to adequately evaluate the product offered to customers. Remember that if you now increase the price and scare off a potential buyer, he will buy shoes from your competitors. You should always be concerned with sales as only sales can allow you to grow and expand your business. It is in them that all the power is concentrated.

Let's stand out and work

To be successful in any market, it is important to stand out. If you fill your store with a variety of shoes from several manufacturers at once, you are unlikely to differ from your competitors. It is much more profitable to create a company store that specializes in the products of one brand, for example, a well-known Russian shoe factory. We're not kidding.

Today there are truly worthy companies in this field in our market. Shoe production in Russia is no different from the same factories in Turkey or Italy. And the advantages and advantages are obvious. Due to the lack of delivery and customs clearance, the cost of shoes will be lower than that of foreign analogues, which means that the product can be sold at an affordable price.

We calculate the expenses and revenues

Expenses within the activities of a shoe production workshop

The project must describe in detail the items of current costs necessary for uninterrupted production and ensuring output volumes corresponding to the amount of demand. Costs also arise in organizational matters, interaction with employees and regulatory authorities.

The structure and volume of expenses are recorded in the shoe business plan as follows:

- rental value of workshop, office and retail space - XXX rubles;

- purchase of raw materials and supplies – XXX rub.;

- prevention, maintenance and repair of lines and equipment – XXX rub.;

- expenses for promotion, PR and BTL activities – XXX rub.;

- employee payroll fund – XXX rub.;

- contributions to the tax authorities - XXX rub.

- other types of operating costs – XXX rub.

The uninterrupted functioning of our enterprise will cost XXX rubles. monthly cash injections.

Profitability of the designed shoe workshop

Profitability is influenced by a number of factors that can shape both positive and negative financial results of a company. In the business plan for footwear production, it is necessary to describe these factors and the assortment sales matrix.

Factors influencing demand and profitability:

- genuine leather for casual and business shoes;

- quality of gluing and stitching;

- design in accordance with fashion trends;

- Comfortable to wear and guaranteed;

- size of the distribution network;

- moderate pricing policy.

Assortment matrix:

- Male models – XXX rub.

- summer – XXX rub.;

- winter - XXX rub.;

- demi-season – XXX rub.

- Female models – XXX rub.

- summer – XXX rub.;

- winter - XXX rub.;

- demi-season – XXX rub.

- Children's models – XXX rub.

- summer – XXX rub.;

- winter - XXX rub.;

- demi-season – XXX rub.

Volumes of sales revenue - XXX rub.

Staffing costs

Considering the specifics of the industry, one of the main requirements for personnel is knowledge of the technology and compliance with the quality of its stages. In addition, designers and experienced specialists in marketing and organizing a sales network for finished products will be required. In the business plan for footwear production, we describe in detail the number of workshops and estimated salaries by position:

- general director – XXX rub.;

- Deputy for commercial issues – XXX rub.;

- chief technologist – XXX rub.;

- accounting – 3 people – XXX rub.;

- HR department – 3 people. – XXX rub.;

- designer – XXX rub.;

- workers of various specialties – 30 people. – XXX rub.;

- Marketing and advertising department – 4 people. – XXX rub.;

- sales department – 4 people. – XXX rub.

Important people

By opening your own store, you are immersed in the service sector. And here attention to the client and courtesy are very important. Pay special attention to personnel selection. If you have enough money, then the best option is a chef and two sellers. Otherwise you will have to combine different positions. The following requirements should be presented to sellers: neatness, sociability, excellent knowledge of shoemaking.

It’s good if a person has several specialized trainings under his belt. Then the sale of shoes in your store will be more brisk. A lot, if not the whole thing, depends on the seller in trade. After all, you may not have a good store, you may not have a great assortment, but if you have ambitious, young and, most importantly, talented employees on your staff who know how to correctly present a product to a person, show it off, so to speak, with their faces, then in this case rest assured: the sale of shoes, or rather, the proceeds from sales, will exceed all your preliminary estimates.

As a rule, a shoe store pays for itself in a year. However, it is better to focus on a longer period, since prices for purchasing products and renting premises will continue to rise. And yet this type of business is considered to be very profitable.

In addition, if you approach your business plan creatively, you can find an excellent niche and gain a good foothold in the market. However, in order to fully enter the market, it is necessary to understand not only how to sell products, but also how they are produced. This is what the next part of our material is about.

Raw materials

To produce high-quality shoes you will need high-quality raw materials. Therefore, include in your business startup plan the search for a reliable supplier of quality leather. It is not necessary to look for them abroad; there are also enough tanneries in the country. For large manufacturers, the minimum order is one ton of leather. But you can find small factories whose minimum supplies start at 300 kg. The cost of raw materials depends on the type of leather. On average, a square meter will cost:

- 100-180 rub. from cattle;

- 50-150 rub. for suede;

- 100 rub. for perforated leather.

Separately, the procurement plan must include various chemical consumables:

- paints;

- liquid polyurethanes;

- reagents for skin preparation;

- adhesives;

- means for processing seams and edges;

- oils;

- cream;

- leather finishing liquids.

Prices for these materials depend on the manufacturer.

A little about technology

Shoe production has several stages. First, blanks for the future shoe are cut out of leather. It’s interesting that there can be up to 30 such parts for one product! This event is successfully carried out thanks to a special press controlled by an operator.

As a rule, in the same workshop the process of cutting out insoles for future boots is carried out, albeit using completely different equipment. First, a special fabric is taken. It is pressed on both sides to form the insole. The resulting blanks are glued with a special rubber glue.

Markers are working in another large workshop. Using a pencil, they draw the lines of future seams. Then all the markings are sent for firing, where, using a special heat treatment, the edges of the parts acquire the desired shape. In the sewing workshop, special machines under the control of experienced seamstresses assemble parts to obtain blanks. After that, thermoplastic inserts are glued into them, with the help of which the boot retains its original shape longer.

Something exclusive

When Grigoriev learned to create basic models of sports shoes, he realized that without a unique design it is impossible to achieve fame and recognition. If the model is poorly thought out and designed, good shoes will not work. At the same time, Vladimir began to master the design of new shoes. After some time, he was able to create his first unique model, which in one form or another is always present in the company’s assortment. These are classic sports style boots.

The next stage of business expansion was the renewal of our own online store. Vladimir planned to make most of his shoes according to individual orders, so he created an online ordering module as convenient as possible for the client. For this, in addition to the standard form, a virtual designer was invented, with the help of which the customer can “see” the desired model in a three-dimensional image, rotate it, select individual parts and even paint it in the desired color.

In addition, Grigoriev launched a new standard for shoe manufacturing: any, even the most complex model is manufactured within ten days. Such a short period is an unattainable ideal for most small shoe shops - where any individual order is completed within a month.

Many features of shoe manufacturing are the know-how of Grigoriev himself. For example, exclusive equipment for making soles. Mass production does not take into account many features of walking and simply glues the finished sole to the workpiece. At the Afour factory, all soles are made independently. For their production, materials are used that meet modern ergonomic and hygienic requirements.

Currently, Grigoriev’s factory is located in St. Petersburg and occupies two small production premises. The entire production was divided into several stages. First - cutting, then sewing, turning the sole, connecting it to the workpiece. Final processing of the product, packaging and dispatch of the order.

Laces at the end

Next, according to the technological process, the resulting product is put on a metal foot, which is preheated to 150 degrees, and then almost immediately removed and cooled at a temperature of -20 degrees.

By the way, both Russian and foreign shoe manufacturers all adhere to approximately the same technology. At the final stage, future boots acquire a sole. It, in turn, goes through its own technological cycles.

Shoe soles should be moderately hard so that the consumer does not injure the foot, and at the same time as comfortable as possible. Manufacturers try to maintain a balance between strength and durability and some lightness.

Shoe soles are usually produced in the same factory as the blanks for future shoes. At the very final stage, the products are polished with special means designed to extend their service life, and are supplied with laces (if necessary). This process, by the way, is carried out manually.

Price issue

Experts note that the optimal area occupied by a factory (taking into account all kinds of warehouses, office departments, and production parts) is approximately 7,000 square meters.

As for production automation, in this area it is far from perfect. Many machines require operators who are involved in the process from time to time, performing their assigned duties.

On average, such production can employ about 250 people. And sometimes much more. It all depends on the number of orders taken by the factory from large wholesalers. Experts have calculated that to organize a shoe factory, as they say, from scratch, you will need to invest about 180 million rubles.

Business organization

Square

The required production area is approximately 7 thousand square meters. m., this takes into account various workshops, warehouses and offices. All communications must be connected to the production premises: electricity, taking into account the load from the operation of machines, water supply and gas pipelines.

Certification

Shoes for adults are certified at the discretion of the manufacturer, while shoes for children must undergo a certification process. Adult shoes must be declared. Produced shoes must comply with the necessary GOST standards and are controlled by the SES. Certificates of conformity and declarations are received by shoes without any manufacturing damage, identical sizes, etc.

Sales

If the product is of high quality and presentable appearance, then the demand will be good, so for its sale you can enter into agreements with large retail chains.

Not so simple

It will pay for itself in about 4 years. Selling the resulting products is a completely separate topic (which we also opened up a little for you). It includes a complex process of marketing and advertising, taking into account the characteristics of the market and offers on it, as well as much more. We sincerely hope that after reading our material you will still want to start a shoe business. You are also motivated and eager to take your rightful place in this market. And the question: “How to start a shoe production?” doesn't seem that difficult to you. You already know almost everything. I wish you success!

Sewing technology

Preliminary materials used in production are necessary:

- carefully check for compliance with quality characteristics;

- sort into production batches;

- send to the cutting shop.

First of all, specialist designers develop the design and appearance of the future model, create a sketch, and prepare a blank.

To create a shoemaking production, appropriate materials are needed, some of them are basic, others are auxiliary.

Basic materials are used for the manufacture of external, internal and intermediate elements of the upper and lower parts of the product:

- different types of leather;

- fur;

- textile materials.

Auxiliary materials include parts intended for finishing and decorating models:

- various shoe accessories;

- textiles and haberdashery;

- glue.

Thus, there is a fairly large selection of materials for making shoes. However, the best of them is genuine leather.

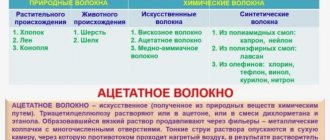

In addition to natural raw materials, synthetic materials have recently been increasingly used for the production of shoes, which are much cheaper. However, many of them are not only cheaper, but often also more practical than their natural counterparts.

Cutting shop

It is in the cutting shop that the creation of a shoe sketch, modeling of the product and cutting of parts are carried out.

Components of shoes are made from pre-prepared material, for which two special punching presses are designed:

- one – for working with the upper parts;

- the second is for the lower parts of the product.

Some parts of the shoes are cut out by hand using a stencil.

Sewing area

The upper of the shoe is made separately from the sole and includes the following parts:

- The front part of the product is the sock;

- The middle part of the product is the vamp;

- The part that fixes the top of the leg is the tongue;

- The back part of the product, fixing the heel - heel.