Before you start implementing a business idea for manufacturing wire, you need to clearly understand what it is.

Wire is nothing more than a metal cord or thread. Its cross-section often has the shape of a circle, hexagon or square.

Let's look at how to organize your own wire production business.

What equipment to choose for wire production

We should also talk about equipment for wire production:

Wet drawing machines that operate using sliding technology and dry sliding machines are very widely used.

The most widely used machine equipment is direct-flow dry sliding due to the most modern design to date.

They are used to produce steel wire with high or low carbon content.

The undeniable advantages of direct-flow dry sliding machines include:

- Compactness;

- Easy to operate;

- Lack of belts and pulleys;

- Silence;

- No vibrations;

- Horizontal arrangement of drums;

- Stability and strength of the frame structure.

When using them, you can easily reconstruct or relocate production if necessary. It is only necessary to install the electrical network in advance.

Dry straight-through drawing machines are modern, ergonomic, economical, and easy to operate, which makes them an almost ideal choice.

Don’t forget about additional equipment: devices that wind and unwind the finished wire. These can be special twisting machines, which are of the drum, cigar or yoke type.

In conclusion, it is worth recalling that the goal of any business is profit, i.e. produce goods that are in demand among customers.

To do this, it is necessary to periodically study the market of supply and demand in order to offer the buyer exactly what he wants.

Advertising plays a big role in the success of any event.

Machine for hand knitting nets

For small production, you can use a hand knitting machine. To start working with it, just select the desired template and insert a bobbin with thread into the shuttle. And the knitting itself proceeds as follows:

- A thread is placed on the selected template.

- The lower part of the machine fits into the cell.

- The thread passes under the shuttle.

- The thread from the shuttle is pulled up and thrown in a semi-ring to the left.

- The mesh thread, passing by the shuttle, comes out from above.

Video: device for tying nets.

Hand knitting machine diagram

- Aluminum tube body.

- Aluminum shuttle with thread slot. The shuttle has a cut at an angle of 45 degrees and a recess for fixing the bobbin in the rear wall, 2.5 mm deep.

- A bronze bobbin that should move freely along the shuttle.

- Aluminum plug with a through hole, 2-3 mm in diameter, for fixing the second end of the bobbin. This plug must be securely fastened into the shuttle.

- Aluminum limiter.

However, this machine is applicable exclusively for home knitting nets; its operating speed cannot allow the establishment of its own stable production. This requires professional equipment.

How much can you earn

The sales that can be achieved from one automated machine can produce 500-600 rolls of wire mesh per month. The average selling price of a roll is 550 rubles. Gross revenue will be 330,000 rubles. Using this figure, the cost calculation will be approximately as follows:

- material costs 120,000;

- rent 10,000;

- wage fund 35,000;

- taxes and other obligatory payments 6,000 rubles.

Thus, net profit will remain about 160,000 rubles monthly.

Manufacturing process

The production of concrete rings begins with preparatory work.

Necessary equipment

First, we assemble the equipment for making concrete rings:

| Name | Purpose |

| Concrete mixer | Brings the cement mortar to the required homogeneity |

| Blanks for rings | They are a kind of removable formwork that allows you to give the product the desired shape |

| Vibrator | Provides vibration shrinkage of the concrete mixture, which avoids the formation of air pockets |

| Winch with tripod | Helps move rings that can weigh more than 500 kg |

| Reinforced frame | Provides the necessary strength to the concrete structure |

Concrete vibrator sample

You should look at the workpiece in more detail.

Ring mold

This is the most important equipment for concrete rings, without which everything else is useless. And you can either buy it ready-made or build it yourself.

This blank consists of the following elements:

- Metal or plastic circles equal to the outer and inner diameters of the ring being poured. When making it yourself, sections of pipes or barrels, as well as thin curved sheets of tin or polyvinyl chloride, fastened together with door canopies or other connecting elements, will work in this capacity. In the most hopeless situation, you can lay out the necessary contours from the boards.

Purchased forms can be divided into component parts for greater ease of use.

- Cone-shaped “cap” for the central glass. This will allow the solution poured from above to flow in the right direction.

Cone shaped lid

Advice: if the production of concrete rings takes place outdoors, it is recommended to add special covers to the structure to cover the solution. This will prevent any debris from getting into it.

Manufacturing technology

The operating instructions for the listed equipment are as follows:

- Place the form on a strong, level and moisture-resistant base.

Cement screed is an ideal platform for pouring rings

- We create a frame from reinforcement by twisting steel rods with soft wire.

Tip: be sure to extend several metal loops around the perimeter of the ring up beyond the fill. The cable will cling to them during transportation, and they will also prevent the products from sliding during installation.

- Mix the solution in a concrete mixer. For this we need the following ingredients:

| Component name | Purpose | Share ratio |

| Cement | Stones, binding fine and coarse aggregate | 1 |

| Sand | Fills pores, reducing moisture absorption rate | 2 |

| Gravel | Gives the finished product high compressive strength | 4 |

| Water | Carry out a chemical reaction with cement, causing it to petrify | 3,5 |

Advice: it is recommended to use cement of at least grade M400. This way you guarantee a sufficient level of adhesion.

Four hundred grade cement

- We lay concrete in layers of twenty centimeters, carefully tamping with a metal rod.

- After the mold is completely filled, we turn on the vibration unit to compact the mixture as much as possible and fill all the pores with it.

- Add concrete if necessary.

- After two weeks, we remove the formwork for the concrete product by first removing the central part and then the outer part.

- We transport the structure to the installation site.

Transportation of finished concrete products

Installation recommendations

The installation of concrete rings is carried out manually using a winch with a tripod, which we keep from production work, and a shovel:

- We dig a hole for the first ring and install it.

Pit for installation of the first reinforced concrete product

- Next, we dig inside it, going twenty centimeters deep.

- Then we remove the soil directly from under the structure, leaving small earthen supports.

- We knock out the remaining soil, after which the concrete ring settles.

- Using this method, we create a shaft of the required dimensions. It is noteworthy that during the entire procedure, concrete barriers will protect you from a possible collapse of the earth.

Digging inside a well

What documents are needed to open

If you intend to sell wire to many construction organizations and wholesale buyers, it is advisable to immediately register a legal entity, namely a limited liability company, when registering a business. To do this, you will need to provide the following list of documentation:

- application form P11001;

- memorandum of association;

- charter;

- conclusion of the owner on the creation of the company;

- passport details of the founders and management.

Copies of documents must be notarized.

Elastic forms for the production of decorative stone

| Photo | Name | Price | To order |

| Elastic mold for decorative stone Slate Natural set of 2 molds, one sq.m contains 12 molds measuring 500×220mm, area of 1 mold is 0.09 sq.m, | 3600 rub. | ||

| Elastic mold for decorative stone Slate Natural internal corner mold size 300×300, in the form of 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Slate Natural outer corner mold size 300×300, each mold has 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Slate Rock, set of 2 molds, in one sq.m. 12 molds measuring 500×220mm, area of 1 mold 0.09 sq.m. | 3600 rub. | ||

| Elastic mold for decorative stone Slate Rock internal corner internal, mold size 300×300, each mold has 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone for Vaulted slate Rock external corner external, mold size 300×300, in the form of 4 segments. | 2500 rub. | ||

| Elastic mold for decorative stone Cliff set of 2 molds, 1 sq.m. 10 molds size 580×230mm, area of one mold 0.1 sq.m. | 3600 rub. | ||

| Elastic mold for decorative stone Cliff inner corner mold size 300×300mm, 1 mold - 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Cliff external corner mold size 300×300mm, 1 mold - 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Old brick in one sq.m. 7 molds measuring 502-440 mm, area of one mold 0.15 sq.m. | 2500 rub. | ||

| Elastic mold for decorative stone Old brick external external corner , mold size 250×250mm, mold capacity 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Old brick internal internal corner, mold size 250×250mm, capacity of each mold 4 segments | 2500 rub. | ||

| Elastic form for decorative stone Wild stone in one sq.m. 6 forms measuring 502x440mm, area of one form 0.17 sq.m. | 2500 rub. | ||

| Elastic mold for decorative stone Wild stone inner corner mold size 300×300mm | 2500 rub. | ||

| Elastic mold for decorative stone Wild stone external corner mold size 300×300mm | 2500 rub. | ||

| Elastic mold for decorative stone Dolomite, set of 2 molds, 1 sq.m. 12 molds 480×230mm, area of one mold is 0.09 sq.m. | 3600 rub. | ||

| Elastic mold for decorative stone Dolomite internal corner mold size 300×300mm, mold capacity 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Dolomite external corner mold size 300×300mm, capacity of one mold 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Old Germanic brick in one sq.m. 7 molds measuring 502-440mm, area of one mold 0.15 sq.m. | 2500 rub. | ||

| Elastic mold for decorative stone Old German brick internal corner mold size 250×250mm, mold capacity 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Old German brick, outer corner mold size 250×250mm, mold capacity 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Flagstone set of 2 molds, one sq.m contains 12 molds measuring 510×220mm, area of one mold is 0.08 sq.m | 3600 rub. | ||

| Elastic mold for decorative stone Flagstone internal corner mold size 300×300mm, mold capacity 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Flagstone external corner mold size 300×300mm, mold capacity 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Canyon set of 2 molds, in one sq.m there are 12 molds measuring 500x220mm, the area of one mold is 0.09 sq.m | 3600 rub. | ||

| Elastic mold for decorative stone Canyon internal corner mold size 300×300mm, mold capacity 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Canyon external corner mold size 300×300mm, mold capacity 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Strength set of 2 molds, 1 sq.m. 12 molds measuring 500×220mm, area of one mold is 0.09 sq.m. | 3600 rub. | ||

| Elastic mold for decorative stone Strength inner corner mold size 300×300mm, mold capacity 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Strength, outer corner, mold size 300×300mm, mold capacity 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Slate Lamellar set of 2 molds, 1 sq.m. 12 molds measuring 500×22 mm, the area of one mold is 0.09 sq.m. | 3600 rub. | ||

| Elastic mold for decorative stone Vaulted slate Lamellar internal corner mold size 300×300mm, mold capacity 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Vaulted slate Lamellar outer corner mold size 300×300mm, mold capacity 4 segments | 2500 rub. | ||

| Elastic mold for decorative stone Brick Old Prague in one sq.m. 12 molds measuring 500x220mm, area of one mold is 0.09 sq.m. | 1800 rub. | ||

| Elastic mold for decorative stone Decorative panel Egypt set of two molds size 610×330mm, mold capacity is 1 segment | 2500 rub. | ||

| Elastic mold for decorative stone Painting Old Town set of one mold size 580×420mm, mold capacity is 1 segment | 3600 rub. | ||

| Elastic mold for decorative stone Decorative elements for stone N1 set of one mold, size 260×300mm, mold capacity is 1 segment | 2500 rub. | ||

| Elastic mold for decorative stone Decorative elements for stone N2 set of one mold size 260×300mm, mold capacity is 1 segment | 2500 rub. | ||

| Elastic mold for decorative stone Decorative elements for stone N3 set of one mold size 260×300mm, mold capacity is 1 segment | 2500 rub. | ||

| Elastic mold for decorative stone Decorative elements for stone N4 set of one mold size 260×300mm, mold capacity is 1 segment | 2500 rub. |

Characteristics of reinforced concrete rings

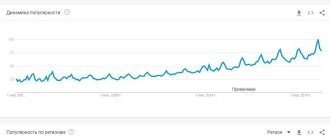

Reinforced concrete rings are widely used in the construction of wells for various purposes, ventilation shafts, bridges, and so on. The rings are manufactured in various diameters, and their design allows for comfortable adhesion between the elements. Thanks to this, the use of reinforced concrete rings is very convenient and economically justified. Therefore, the demand for this material has a positive trend.

Reinforced concrete is a combination of steel and concrete. Steel rods, which are used as reinforcement (from 4 to 10 mm), cope well with tension, and durable concrete tolerates compressive loads well.

Technology for the production of reinforced concrete rings

Schematically, the production process of reinforced concrete rings is as follows.

Organizational aspects

To organize a mini-production, it is enough to attract only 5-6 people: a couple of general workers, a couple of loaders and a molder. To increase labor motivation, it is necessary to establish piecework wages for them.

OKVED for an enterprise specializing in the production of reinforced concrete rings

The organizer of a business for the production of reinforced concrete products, even at the stage of registering a company, must select the appropriate codes, according to the all-Russian classifier of types of activities. For a company that produces concrete products, these are: OKVED 26.61 (production of concrete products) and OKVED 51.53.24 (sale of building materials).

( 5 ratings, average: 2.00 out of 5)

Loading…

Similar business ideas:

- Concrete production plant - 7 steps to implementation...

- TOP 30 business ideas with minimal investment

- TOP 30 business ideas without investment

- Chatbot marketing: is it possible to get a good income...

Where to start?

Before you start organizing production, you need to find out everything about your competitors. The plant is not a rival. As a rule, factory prices are inflated, so there is little demand here. Serious competitors are private entrepreneurs. If there are few of them, you can safely get down to business.

- First, you need to register an LLC or, depending on who the businessman plans to work with.

- Secondly, any product must have a quality certificate. In this case, it is enough to request this document from the manufacturer when purchasing concrete. Based on it, fill out your certificate.

- It is best to start making rings in early spring. At this time of year and until December, products are most in demand. Well, in winter, entrepreneurs sell the remaining goods.