Features of socks production

Like any other business, the production of hosiery products has its own characteristics. First of all, it is worth considering the peculiarities of the socks market in Russia.

After all, there is quite a lot of competition in this field, but not all manufacturers can boast of decent product quality and at the same time an affordable price. In general, all products of the Russian socks market can be divided into 3 main types:

- First view. This includes products made in European countries (Germany, Poland, France, Italy and others) and some Asian countries (Turkey, for example). They make high quality products from good raw materials. This also includes a small part of Russian manufacturers who work on new high-quality equipment, and some Chinese manufacturers. Some Chinese-made goods are of fairly good quality, but their prices differ from the cheap analogues that fill most store shelves.

- Second type . These include products from post-socialist countries (Belarus, Lithuania), which work with domestic and imported raw materials. They also include products of Czech and Hungarian production. The quality of these products may be slightly inferior to the previous ones, but they still make fairly good products at an affordable price.

- Third type . This type includes the well-known cheap Chinese products, as well as products from some other Asian countries (Uzbekistan, Vietnam, Cambodia, Turkmenistan) and some domestic factories that operate on outdated equipment. The quality of such products leaves much to be desired, and the price is very low, due to which they will always find their buyer.

About half of the market is occupied by products of the second type, the first and third types - 30% and 20%, respectively.

It makes no sense to compete with cheap Chinese goods. You physically will not be able to produce so many products, and besides, it will be completely unprofitable. Therefore, it is worth taking a closer look at the first two types and focusing on them. The Russian market needs high-quality, inexpensive products, because the crisis dictates its own rules, and you want to use high-quality products without compromising your budget. Therefore, today this price category is considered the most promising.

Socks against boredom: how a marketer broke the stereotype and created a fashion brand

By 2002, he got bored with working in the press, and he switched to advertising - for two years he worked as a marketing manager for the Ekaterinburg Tinkoff restaurant, then he was appointed director of the advertising department of the entire restaurant chain and transferred to an office in St. Petersburg. Before opening his own business, he managed to work as a marketer in three more places - on the Geometria.ru website, in the St. Petersburg tourist and New Pharmacy chain.

But Tonkov always dreamed of his own business. “I’m a creative person, so I was looking for an idea at the intersection of business and creativity,” he says. “When I found out that the production of socks is quite affordable in terms of investment and management, I began to look into it further.”

Read on RBC Pro

Out of spite Kawasaki: how loyalty defeated competence in Russia Billionaire downshifter: how a mortgage seller got rich by comparing prices So says Gref: there are few people with a “nuclear engine” inside Hiring with a demotion: is it worth hiring a former manager for a linear position

I wanted to start small - place orders for the production of socks at existing production facilities in Russia. But it turned out differently. In the summer of 2015, Tonkov found an advertisement on Avito for the sale of the Noskof factory in the village of Razbegaevo, Leningrad Region. “I immediately went to see this enterprise,” says Tonkov. — They made black, gray and white socks according to GOST: not very wearable, but not falling apart after the first wash. It was something we could work with."

Factory with an area of 350 sq. m with a warehouse were sold for 10 million rubles. The previous owners had no time to deal with it: their main business was the production of metal structures. In addition, the business brought in almost no money. According to SPARK-Interfax, in 2014 the company’s revenue was less than 1.5 million rubles.

Tonkov did not have 10 million rubles, so he started looking for a financial partner. Sergey Zhivotov, his acquaintance from one of his past projects (he was a co-owner of Geometria.ru), agreed to become an investor. “I told him how, when and what we could come to,” Tonkov recalls. - Naturally, these were all assumptions. The business itself was still incomprehensible to us. But Zhivotov agreed.”

The partners acquired the company in early September 2020. The only condition of the Noskof seller was to leave all the workers who live in Razbegaevo at the factory. This was to Tonkov’s advantage: he did not need to look for personnel for production.

It took about two months and 2–3 million rubles to modernize the enterprise, search for yarn and determine knitting parameters. Tonkov's personal funds. From the very beginning it was clear that there was no point in selling cheap socks, which means they must be of high quality and contain at least 80% cotton. It was not possible to find such yarn from domestic manufacturers. “Russian manufacturers make only synthetic and blended yarn, which contains 50% cotton or less,” says Tonkov. “The fibers of this yarn are short, so there are a lot of tears when worn.”

Photo: Askhat Bardynov for RBC

In October 2020, Tonkov entered into an agreement with Rivage, which distributes Turkish yarn, and began preparing the first collection. At the same time, he independently developed a website and set up online advertising. “I didn’t come up with the name St.Friday Socks right away,” says Tonkov. — At first I complained to friends that all possible words on the Russian and foreign markets were already taken. But once at a friend’s birthday they told me: the company is from St. Petersburg, call it Saint Socks. And then I remembered that Friday when the idea came and everything came together in St. Friday Socks.”

The first collection consisted of 80 models: 15–20 prints in different colors. The main difference from competitors was the aggressive color combinations: white and red, black and orange. “We opened urgently at the request of my friends. Everyone wanted gifts for the New Year,” Tonkov laughs. The first customers, who bought about 2 thousand pairs, came mainly through Facebook.

City fairs have become an additional channel for promoting St.Friday Socks. “The markets became free focus groups for us. I stood behind the counter and asked people everything. I wanted to see my clients and understand why they buy bright socks,” says Tonkov. — The most important conclusion I made is that we are on the right path. Most clients have only recently switched to designer socks. That is, demand is just beginning to form.”

Stylish detail

According to Fashion Consulting Group, imports of hosiery in Russia in 2020 decreased by almost 30% compared to 2015, and domestic production grew by 7%. Most socks are sold in the budget segment (from 50 to 200 rubles per pair). St.Friday Socks belong to the middle segment; their retail price averages 300–400 rubles. for a couple.

“Socks, an intimate part of the wardrobe, have become an accent element of the image in the wake of the main fashion trend - individualization and freedom to choose your own image,” says Anna Lebsak-Kleymans, CEO of Fashion Consulting Group. — In Europe and the USA, bright socks have already moved from the conceptual category to the category of mass-market products. The first to master it many years ago were, for example, the Swedish Happy Socks and the American Soxfords.”

Russia, as usual, lags behind, but now the market for unusual socks in the country is beginning to grow. Most of the large domestic manufacturers are focused on the traditional mass market and therefore continue to produce the usual monochrome assortment, which is in guaranteed demand. The main players in the bright socks segment were the startups St.Friday Socks, Happy Socks, Funny Socks, Sammy Icon, Zaporozhets, as well as international lingerie and hosiery brands (Calzedonia, Falke, etc.) and international chains (H&M, Zara, Uniqlo, Mango, etc.), which also included colored socks in their range.

Photo: Askhat Bardynov for RBC

Socks between books

When the New Year's rush subsided, Tonkov began to negotiate the sale of St.Friday Socks with grocery retailers (Azbuka Vkusa, Bakhetle, Metro Cash & Carry, etc.), fashion stores (TSUM, Podium Market, Streat Beat, “Econika”, etc.) and even bookstores, which are actively increasing sales of souvenirs (“Read-city”, Moscow House of Books, “Bukvoed”, etc.). But no one wanted to sell expensive socks. “I didn’t expect that we would face such a failure,” Tonkov recalls. “Everyone said: “We’ll keep an eye on you.”

We observed for six months. All this time, Tonkov was content only with retail sales on the website and single wholesale orders. With average revenue of 500–600 thousand rubles. the business was making losses per month. “I spent my own savings on advertising and employee salaries, plus my mother helped. That’s how we survived,” says Tonkov.

In addition, for some reason the aspiring entrepreneur opened an office in St. Petersburg. “We sat in this office for probably only six months, after which I realized that this was a wrong move,” Tonkov admits. — The sales department still sits at the factory, assembly also takes place at the factory. We closed the office because we were throwing 80 thousand rubles down the drain. per month".

Sergey Tonkov (Photo: Askhat Bardynov for RBC)

In the spring of 2020, he was finally contacted by one of the employees of the St. Petersburg book chain “Bookvoed”, to whom St.Friday Socks offered cooperation back in the winter. She said that Bookvoed is ready to place racks of designer socks in the souvenir department. In May, Tonkov made the first delivery of 700 pairs, and St. Friday Socks appeared in several stores in the chain. Soon, on the eve of the World Hockey Championship, socks with hockey symbols were purchased by ABC of Taste.

In the spring of 2020, the entrepreneur released his first lookbook - a catalog of St.Friday Socks photographs. For the shooting, Tonkov invited stylists working with fashion magazines and department stores, and freelance photographers. In total, the catalog cost him 200 thousand rubles. However, it did not bring any new clients.

Then Tonkov decided to try his luck a second time; he decided to release a second lookbook - a series of photographs of the new collection, released in collaboration with famous Moscow designers. “The famous buyer Gosha Rostovshchikov, who at that time collaborated with Podium Market, helped me a lot,” says Tonkov. “He introduced me to designers Alexander Arutyunov, Oleg Ovsiev and Konstantin Gaidai and convinced them to release a joint collection.” Gradually, with the help of his acquaintances, Tonkov assembled a team of six fashion designers, under whose names six limited collections were released.

Thanks to the fact that some designers carried out the shooting themselves and sent finished photographs to the entrepreneur, the new lookbook cost only 20 thousand rubles. Tonkov paid the designers royalties based on sales. He spent about 200 thousand rubles on payments to all designers in the fall of 2020. “I tried to squeeze every possible PR opportunity out of the collaboration,” he says. “And I succeeded: the entire fashion elite drew attention to our socks.”

Retailers Podium Market, Yunost, Good Local, Expedition, Capsula, Moscow Socks Club, Trends Brands have been added to St.Friday Socks clients. Following them, the largest online clothing hypermarket Wildberries came with an order. In addition, the company began to receive requests for the production of socks under the chain's trademarks. For example, Tonkov made several sets of socks under the Testosteron brand for the Red Cube gift shops. True, most retailers took the goods for sale and did not pay immediately, but only after someone bought the socks. “Back then we supplied a lot for sale simply because we wanted to be present on store shelves,” says Tonkov.

According to SPARK-Interfax, the total revenue of the legal entities of the project, LLC Noskof and LLC Friday, for the entire 2020 amounted to 15.5 million rubles, profit - 236 thousand rubles. 70% of all funds earned came from wholesale sales, the rest came from the online store. “It got to the point that business stopped eating up my personal funds and I set myself a salary,” Tonkov rejoices. “But there was practically no profit due to the fact that we spent a lot on advertising and packaging testing.” Thematic sets of socks from St.Friday Socks are now sold in cardboard and even wooden boxes - this increases the manufacturer’s costs, but gives the product a premium look and allows it to be positioned as a gift.

Photo: Askhat Bardynov for RBC

In fact, designer socks are a very marginal product. The cost of a pair of St.Friday Socks is 40 rubles. (and ordinary black socks can be made for 3 rubles.) Their price on the store shelf reaches 400 rubles, but the retailer takes most of the margin. In September 2017, the company received 2 million rubles. revenue and about 200 thousand rubles. arrived.

The problem was also that the retailer was in no hurry to pay for the goods taken for sale. “For several months they simply deceived us, showing statistics on sales of 50-100 pairs per month. In fact, they sold many times more products, but did not transfer the funds to us,” says Tonkov. — For debts up to 30 thousand rubles. We didn’t even go to court.” Large debtors had to go to court: the entrepreneur won several cases, some are still being considered by the courts. For example, according to Tonkov, Podium Market paid regularly at first, but stopped in the spring of 2020. “We submitted an application to terminate the contract in April, and since then we have not been able to receive either goods or money,” Sergei sighs. The total debt of Podium Market to St.Friday Socks amounted to more than 700 thousand rubles. However, according to Vedomosti estimates, in total in 2020, 64 claims from counterparties were filed against Podium Market for a total amount of more than 1 billion rubles. Now the network is coming under the control of Stockmann, and no one knows when it will pay off its payments to suppliers. After this incident, Tonkov stopped working with retailers on sales terms and began demanding prepayment.

Tonkov associates the development of the project with supplies abroad. “We have already received more than a hundred requests from all over the world from people wanting to buy our socks,” he says. It is difficult to establish exports: the goods are inexpensive, and the cost of delivery eats up a significant part of the margin. However, St.Friday Socks are already sold in several offline stores in the USA, Finland, Estonia, Latvia, Greece and Kazakhstan.

View from the outside

“We weren’t afraid to combine socks and books”

Olga Rogozina, head of the system communications department of the Bukvoed book chain

“We liked St.Friday Socks products right away. It was quite suitable for our new product group “products for self-expression”. It includes all products that allow a person to express his personal aesthetic tastes: T-shirts or bags with book and literary themes, quotes; caps, notepads, mugs. Such subcultural manifestations seem very promising to us. We are optimistic about the development of this product group and assume that it will occupy more than 5% of the company's total turnover. We were not afraid to combine socks and books, because we are used to surprising our customers and being ironic.

Sergey not only offered us his product, but also listened to our recommendations and changed the packaging design. The socks are popular, with sales peaking during the Christmas gift season. We are currently looking for opportunities to expand both the St.Friday Socks line and the entire “products for self-expression” trading group.

“Producing socks is one of the simplest”

Mikhail Labakhua, director of brand development "Zaporozhets"

“For the last few years, people have not been shy about wearing colored socks. Previously, it was a shame: people thought it was something indecent. Now they believe that such products can at least be given as a gift. Due to the increased interest in colored socks, new players have appeared. Since the production of socks is one of the most simple and quite developed in our country, the barrier to entry into the market is low. You can place orders at existing production facilities, or launch your own factory. The development of this segment can be judged by the appearance of racks with colored socks in shopping centers. Now I can say with confidence that we have our own strong players in this segment. Their advantage over Western brands is in price and speed of delivery.”

How socks are made: 5 stages of production

The production of sock products does not require a huge amount of equipment, but still, one machine at all stages of product manufacturing is not enough.

The process itself is quite simple and takes place in several stages:

- The base of the sock is made. First, the main part of the sock is formed on a special knitting machine. Depending on how fine the yarn is needed and what raw materials are used in production, the type of machine will differ. The density of the product will directly depend on which needles are used. The thinner the needle, the tighter the sock.

- The toe of the sock is sewn up. This stage takes place using a kettel machine. The machine can be semi-automatic (preferably) or manual. Since the sock processing process requires a worker to manually place each warp on the machine, it cannot be fully automated. And further processing takes place without human intervention.

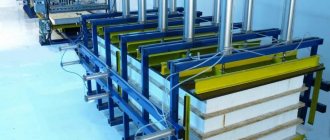

- The socks are formed using a press, and then the base is steamed using a special unit. Drying of the product also occurs at this stage. It uses semi-automatic pressing machines, which are controlled by only one worker.

- At the next stage, the products are marked, embroidered, and a logo is applied. This process can take place in different ways depending on what equipment is used.

- The last, final stage is the packaging of the finished product. Some manufacturers ignore this element, considering it an unjustified waste of money, but this is not at all the case. It is the packaging that attracts the first attention. Therefore, it is important that it stands out among others and attracts the attention of potential buyers.

There is nothing complicated in the production of socks. It is quite easy to master in a short time, after which you can start working.

Is it possible to start your own socks production at home?

If you want to start your own socks business, but you don’t have enough money to rent premises, hire staff and a lot of equipment, you can start your business from your home - provided that you have enough space to accommodate the main equipment. You can buy several necessary machines, a small batch of raw materials and get down to business.

For those who have design skills, this is a good chance to show creativity and come up with truly unusual and stylish products. Exclusive handmade goods are now gaining popularity. If you make your products unique, you can make good money at home.

How to open a business

Registering a business is the most exciting moment, especially for beginning entrepreneurs. To open your own hosiery business, you don’t need a lot of documents and permits.

You can open both an individual entrepreneur and an LLC. If you do not plan to launch a huge business in the future, reach large customers and work throughout the country, then it is enough to open an individual entrepreneur. If your plans are different, it makes more sense to open an LLC right away. However, the registration process will take a little longer and will cost more.

When choosing a tax system, it is more profitable to choose the simplified tax system. You will also need permissions from services such as:

- Rospotrebnadzor.

- SES.

- Fire inspection.

You can find a complete list of documents required for this on the websites of the relevant services.

To make hosiery you will need OKVED code 14.31. This includes knitted and knitted products.

Organizing a business from scratch

Registration of production

If you plan to produce socks exclusively for your region and sell them in small batches, it is enough to register as an individual entrepreneur. If an entrepreneur is going to cover the national market, attract investors, find large buyers and suppliers, and also if he organizes a business on a partnership basis, it is advisable to open an LLC.

It is better to choose a simplified taxation system, a suitable activity code according to OKVED - 17.11 - it works in the production of hosiery products.

Obtaining Permits

Before starting work, you should obtain permission from regulatory authorities:

- SES;

- fire supervision;

- Rospotrebnadzor.

Before the fire inspection, it is necessary to install a fire alarm, smoke and fire detectors, automatic fire extinguishers in the workshop, and provide good ventilation. Rospotrebnadzor will check the compliance of goods with GOST, in this case, GOST 8541, which regulates the quality of hosiery products produced on automatic circular hosiery machines. The SES will check the equipment and premises for readiness for operation and their compliance with sanitary standards.

Rent of premises for a production workshop

To organize a workshop you will need to rent a suitable premises. Its location is not critical - you can use a garage or production hangar outside the city - this way you can save on rent. The workshop area depends on the volume of production and must be sufficient to accommodate all the equipment and comfortable work for the staff.

Purchase of equipment

To make socks, you will need to purchase:

- 2 knitting machines;

- 1 kettel machine;

- 1 automatic or semi-automatic molding machine;

- 1 packaging line, including a unit for supplying products with labels.

Buying used equipment can save a significant amount, but it is more advisable to purchase new machines - they provide higher productivity and product quality.

You will also need a certain amount of workshop and office furniture - tables, chairs, shelving, etc.

Recruitment

The number of employees also depends on the volume of production. There are no special requirements for employees, but their knowledge in the field of hosiery production and work experience are welcome.

At first, administrative tasks will be performed by the business owner himself, after which you can hire a manager. Accounting is entrusted to a visiting specialist. Two guards working in shifts will be responsible for the security of the premises during non-working hours.

What equipment is needed to produce socks?

To produce socks, you will need several types of installations, which are used in turn at all stages of production.

Their number and power depend on the volume of products you will produce. Below is an example of a list of basic equipment for small production.

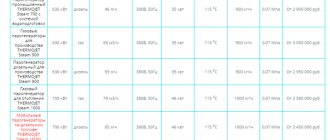

| Name of equipment | Quantity |

| Knitting machine | 4-5 |

| Molding plant | 2-3 |

| Sewing machine | 2-3 |

| Packing machine | 1-2 |

The cost of the equipment will differ depending on which manufacturer you choose and whether you buy new equipment. On average, new equipment will cost about 1.8 - 4 million rubles.

Why do you need a sock knitting machine?

A knitting machine is the unit where the base of the product is made. It directly affects the quality of knitting, density and other elements of the product. Also, what size cylinders you use will determine what size socks you end up with. For example, for men's sock models, diameters of 3.5-4 inches are suitable. For women's products, it is necessary to acquire smaller diameters.

What should a knitting machine be like for producing socks?

The quality of your knitting machine will be reflected in the quality of the finished hosiery products. The machine must be selected based on what products you are going to produce, in what volume and from what raw materials. These characteristics determine which unit is best suited to your needs.

It is also important to carefully select your machine supplier. Domestic manufacturers, as a rule, make relatively inexpensive cars, but this will affect the quality of the product. Chinese and Korean analogues will cost a little more. But their quality is also inferior to European standards. Italian and Czech equipment will cost much more. But this way you can produce truly high-quality products.

What products can be produced using a sock knitting machine?

You shouldn’t stop at just one type of hosiery. After all, there are a lot of them, and the larger the assortment, the greater the turnover and profit of production. Of course, subject to excellent quality, interesting design and competitive prices.

It’s better to start with one type of product – for example, men’s socks in dark colors. They are in greatest demand. Once you have mastered this segment, you can start producing women's socks, adding different colors and original design elements.

In addition, it is also worth taking a closer look at other types of products. You can start making tights, leggings, and knee socks. Various headbands and tops for dress boots can also be made on knitting machines. This should be taken into account when expanding the range.

What to look for when buying a sock knitting machine

When choosing a machine, be sure to pay attention to how suitable it is for the production of your products, is it powerful enough? After all, it depends on how many pairs of socks you will produce. At the initial stage, a small factory can produce 300-500 pairs of socks per day. Also pay attention to other technical details.

If you are planning to purchase used equipment, think about how profitable such an investment is. The machine may already be pretty worn out and often break down: then you will spend much more on repairing it than you could save. If you definitely decide to buy such a machine, seek advice from a specialist who can objectively assess the condition of the unit.

Range

At the very beginning of production, it is better to produce one type of product. These can be basic models for men in dark colors made of cotton. Then gradually add women's and children's models.

You can increase the number of assortments by creating:

- author's design (installations of characters from popular films, games);

- tights, stockings, leggings or knee socks;

- woolen products;

- knee pads, elbow pads;

- bandages for arms and head.

Selection of raw materials and suppliers

The quality of raw materials plays a significant role in the production of socks. After all, it depends on how durable, pleasant to the touch and high quality the socks will be. The highest quality products are made from natural materials.

There are 3 main types of raw materials:

- Threads made from animal materials (silk and wool). These include angora, merino wool, cashmere, silk and others.

- Threads made from plant materials. Various types of cotton, viscose, linen, bamboo and their mixtures. They are the most popular, especially in the warm season.

- Synthetic threads. Often used with an admixture of natural threads.

The quality of the same materials may differ from one manufacturer to another. Italy produces the highest quality materials, but they are more expensive. Good raw materials can be found from Indian manufacturers. Chinese and domestic manufacturers are not of high enough quality. Many materials are not even produced here, so some of the raw materials will have to be ordered abroad.

To do this, thoroughly study the supplier base and choose the best option. It is better if you have two or three suppliers. If someone has problems with timely delivery or does not have the right material in stock, you can turn to others.

Room

The place where you will locate the production must be large enough to accommodate the required amount of equipment, while workers must move comfortably while working. The optimal area is from 100 square meters. measures. Don't forget that you also need to store raw materials and finished products. All necessary communications must be provided in the premises.

Recruitment

To work in a small production facility in two shifts, four workers are enough, as well as a security guard, a technologist and a cleaner. Auditing and marketing services can be outsourced, and the business owner himself can deal with financial issues, procurement and sales of products.

If you buy European equipment, the supplier will perform all commissioning work and train staff free of charge.

Domestic market research

Before opening a mini sock production, you need to study the market, the relationship between supply and demand, and trends. Today, Russian manufacturers supply 50% of the total volume of socks sold on the domestic market. But the quality of products imported from China, Turkey, and India often leaves much to be desired.

Russian entrepreneurs have a huge advantage over foreign suppliers: they know exactly what properties of a product can attract the attention of their compatriots. For example, the production of woolen socks can satisfy the needs of the majority of the population, because this type of product is relevant for residents of Russia.

Another advantage can be considered the fact that the domestic manufacturer will not have to pay import customs duties or overpay for the transportation of products, which will have a positive effect on the cost of products sold. The optimal price-quality ratio is what every buyer focuses on when choosing a product.

Knitted products have always been in good demand and are considered one of the most sought-after products. Having started the activity with the production of men's socks, and having determined the target audience, the entrepreneur should begin producing products for women and children, the range of which is limitless. You can sell products through retail chains, online stores or your own retail outlets.

How much money will it take to open?

The bulk of the money will be spent on purchasing equipment. But besides this, there are several costly expense items.

Below is an approximate list of the main cost items for starting a business:

| Expense item | Amount in rubles |

| Registration and taxes | from 20 thousand |

| Equipment | 1.5-4 million |

| Purchase of raw materials | from 35 thousand |

| Communal expenses | from 10 thousand |

| Rent | from 25 thousand |

| Salary (6 people) | from 125 thousand |

| TOTAL | 2.025 - 4.025 million |

As a result, the approximate amount for starting a business is from two to four million rubles. The amount varies depending on your region, the choice of suppliers of raw materials and equipment, and the scale of production. Read how to find an investor.

Where to sell products and how to promote your business

With the development of the Internet and shopping and entertainment networks, it is now not difficult to find a way to sell your products. You can sell socks to wholesalers, arrange for the supply of products to retail stores, create your own website for this, or use social networks. It is best to use several distribution channels.

When will the investment pay off?

If you work in two shifts of 10-12 hours, then 1 knitting machine will produce about 400-500 pairs of products. If there are four machines, then approximately 1600-2000 pairs. Up to 60,000 pairs can be produced per month.

The wholesale cost of one pair of products is approximately 10-15 rubles. In this case, the maximum revenue at 100% sales without deducting expenses will be 600-900 thousand rubles. Net income minus rent, wages, taxes, utility bills and other deductions - from 100 to 500 thousand rubles. Of course, it will be difficult to achieve such indicators in the first months of work. On average, the payback for such a business is 1.5-2 years, but with a competent approach and hard work, the period can be reduced to 7-9 months.

Financial calculations

Investments in a business project

The starting investment in the business will be (in thousands of rubles):

- opening of an enterprise – 10;

- rental of premises during the preparatory period – 10;

- purchase of equipment – 2000;

- initial purchase of raw materials – 50;

- advertising campaign – 50;

- reserve for unforeseen expenses – 10.

Total: 2.13 million rubles.

Current expenses

Per month, the maintenance of the enterprise will require (in thousands of rubles):

- premises rental – 20;

- purchase of raw materials – 25;

- advertising campaign – 10;

- utility bills – 20;

- staff salary – 100;

- reserve for unforeseen expenses – 10.

Total: 185 thousand rubles.

Sales income and profit calculation, project payback

During a work shift, 2 knitting machines will be able to produce 600 pairs of socks, per month (with a 5/2 operating mode and two shifts per day) - up to 24 thousand units of production. The wholesale price of 1 pair is 10 rubles. Monthly revenue will be 240 thousand rubles.

Production profitability – 23%. The payback period is 39–40 months.

Making socks is a great business idea. If the business is organized correctly, it will definitely bring success to its owner.