Vinyl wallpapers

This coating reliably imitates various natural materials and is durable and water resistant. Therefore, this type of wallpaper is often used for covering bathrooms, hallways, kitchens, that is, rooms where there is high humidity or frequent wet cleaning is required. However, the material has a drawback - it does not allow air to pass through well. Although modern wallpaper production technology makes it possible to produce coatings with micropores that provide ventilation.

The material consists of two layers. The bottom - a non-woven or paper base - is covered with a thin layer of polyvinyl chloride, and then embossing or a design (or both) is applied to the surface. During the production of wallpaper, they are usually impregnated with a special composition that protects the walls from the formation of fungus and mold.

General information. Types of wallpaper

If you decide to start producing wallpaper, then first you need to decide what types of wallpaper you will make. Depending on the type of material, wallpaper can be fabric, polymer or paper. According to the type of moisture resistance, wallpaper can be super washable, washable, moisture resistant or non-moisture resistant. Based on the type of surface, they are divided into smooth, embossed and textured. By type of density: light and heavy. There are quite a few types of wallpaper.

- Wallpaper for painting

Today this type of wallpaper is very popular. Such wallpaper does not have multi-colored patterns or varied relief. Such wallpapers are also called structural or textured. Their main feature is that this material can be painted with any dispersion paints.

- Vinyl wallpapers

This type of wallpaper is distinguished by the fact that it faithfully imitates various natural materials, while being water-resistant and excellent strength.

Wallpaper of this type is often used for rooms with high humidity or requiring frequent cleaning, such as bathrooms, kitchens, and hallways. But such wallpaper also has a disadvantage, which is that it does not allow air to pass through well. REFERENCE! However, at the present stage it has become possible to produce wallpaper with micropores that provide ventilation. Vinyl wallpaper consists of two layers. The bottom base can be paper or non-woven, covered with a thin layer of polyvinyl chloride. The design and/or embossing is applied to this surface. During the production of vinyl wallpaper, they are usually impregnated with a special compound that protects the walls from mold and mildew.

- Paper wallpaper

This coating is the cheapest and easiest to use. This coating is characterized by environmental friendliness, breathability, and also, if it is treated with a special impregnation, moisture and wear resistance. There are quite a few different options for the production of paper wallpaper: they can be single-layer or multi-layer, have a smooth or structured surface.

- Velor wallpaper

This type of wallpaper is made on the basis of paper or non-woven fabric, on top of which a fleecy coating with a pattern is applied. This material has high decorative properties, but it is very difficult to care for and is afraid of water. If it gets on this material, the adhesive layer may dissolve and the coating will delaminate.

- Quartz wallpaper

This type of wallpaper consists of a non-woven base and a top quartz layer (dyed sand). This type of coating is resistant to mechanical damage and abrasion. In addition, due to its painted base, the joints of the paintings on the walls are almost invisible, resulting in the effect of a uniform coating.

Plant equipment

The standard equipment required for the production of canvases includes:

- Storage device. Necessary for holding paper, thanks to it you can change rolls without stopping the line.

- A device with a rotating template with which the coating is applied.

- A conditioning device designed to reduce moisture in the fabric.

- Printing section with intermediate vertical dryers.

- A rotating device that performs the function of turning the canvases over to the reverse side.

- A drying chamber in which the paste is dried, foamed and gelatinized, which is subsequently applied to the coating base.

- Calender required for flattening and embossing, including infrared heating.

- An edger designed for cutting edges.

- Packaging line. Allows you to pack finished products in shrink film.

A production line with such equipment will cost from 30 million rubles if used devices are purchased. In addition to the listed machines, it is necessary to purchase auxiliary devices, namely a raw material returner, a mixer, and a boiler.

Wallpaper production should be organized in a room with an area of at least 1800 square meters. To service the canvas manufacturing process, a staff of at least 15-18 people will be required.

Details

Wallpaper - production technology

To produce wallpaper, you may need a different number of production lines, depending on the planned production volume and what types of materials you will use. Typically, production starts with one or two lines, gradually expanding. The production capacity of one line can be 3-4 million eurorolls of wallpaper over a period of operation of 300 days a year for 18 hours a day.

IMPORTANT! When purchasing equipment, it is better to choose it of German, English, Dutch or Belgian manufacture.

List of required equipment

The following types of equipment are usually required for the production of canvases:

- Storage – needed to hold paper, helps replace rolls without stopping the line.

- A device with a rotating template - necessary for applying the coating.

- Conditioner - needed to reduce humidity in the canvas.

- Printing section with vertical intermediate front sights.

- Device for turning sheets over to the other side.

- The drying chamber is necessary for drying, foaming and gelatinizing the paste after applying the coating to the base.

- Calender - needed for alignment and embossing, plus infrared heating.

- Edger - necessary for cutting edges.

- Packaging line - needed for packaging finished products in shrink film.

A wallpaper production line consisting of the equipment listed above can cost from 30 million rubles if you buy used equipment. In addition to these machines, you will also need to buy auxiliary equipment, such as a boiler, mixer, and raw material returner.

To make wallpaper, you need to find a room with an area of at least 1800 square meters. The number of employees required to service the production process is at least 15 people.

Creating a drawing

The most important department of a wallpaper factory is the design center, where wallpaper designs are developed. Artists print out new prints on paper, after which they assign a specific name or numerical code to it. The prepared sketch is then discussed by experts and if they approve it, the drawing is transferred to software engineers. They are refining the image and bringing it into compliance with the requirements of state standards. After all this, the drawing is handed over to the colonists, who select a color palette.

REFERENCE! The actual production of wallpaper begins when the picture is completely ready.

Raw materials

For the manufacture of wallpaper, raw materials must be used that meet the technical specifications. Raw materials are supplied in rolls 550 or 620 millimeters wide. The maximum permissible deviations are no more than two millimeters. If wallpaper is made to order, the rolls may be of a different width. The diameter is generally 700-900 millimeters.

Paper is made from softwood pulp or bleached hardwood pulp. The paper must have the following characteristics:

- equal thickness;

- smooth and clean cutting of edges from the ends;

- dense and uniform winding.

No folds, stripes, stains or tears are allowed on the surface.

REFERENCE! Usually, expensive wallpaper is made from foreign, higher quality and more expensive raw materials. Inexpensive, budget wallpapers are made from domestic materials.

In addition to all of the above, production requires raw materials such as paints, varnishes, polymer pastes, and so on.

Printing a drawing

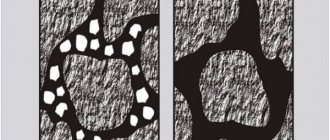

In order to print a design on a canvas, embossing rollers (printing forms) are placed on the equipment. Then paper rolls are installed there. The shafts are each dipped in a different color of paint and printed. Wallpaper production is controlled by the computer and the printer.

You cannot mix paints, as in this case the picture will float. If technology requires this, then it is necessary to apply foam paint to the paper base. After this, the canvas is judged under high temperatures. As a result, the paint foams and a relief is obtained. Often, wallpaper is additionally coated with a waterproof compound to create a canvas that is resistant to moisture. The relief is given to the pattern on the embossing unit.

Then the material enters a special workshop, where the individual webs are glued together. After all this, wallpaper samples are sent to the quality control department. There they are tested for strength, abrasion resistance and other indicators.

REFERENCE! If the material passes the test, it is dried, rolled and packaged, after which it is sent to the warehouse.

Profitability of the wallpaper production business

It is clear that wallpaper production is a large-scale and expensive business. For this reason, many businessmen planning to engage in this activity are concerned about whether their investment will pay off. There is no definite answer to this question, because it is difficult to predict how the business will develop several times forward. This is due to the fact that the wallpaper market is not stable. There is a demand for wallpaper, but there is none.

However, forecasts for the coming years indicate that the demand for this material will only increase, because people still choose wallpaper as a finishing material for their houses and apartments.

This means that the market segment in question continues to be promising for investment. In addition, by offering a product with an original design and excellent quality, you will ensure demand for it. And of course, the price should also be competitive.

A little about design

Today, domestically produced wallpaper has a rather meager range of colors and a monotonous design. For this reason, people are choosing foreign options more and more often. But you can capitalize on this by hiring qualified and experienced designers to diversify the collections you produce. Then it will be possible to set the price for your products above average.

Sales markets

It is imperative to decide where you will supply your products in advance. Initially, you should focus on large cities and industrialized regions. There is an option to sell finished wallpaper to construction stores or markets. The second sales option is to create your own points of sale. It is clear that this cannot be done without an advertising campaign.

REFERENCE! Advertising in newspapers, television and transport brings a tangible effect. However, today, advertising on the Internet is becoming increasingly widespread. And even wallpaper sales are increasingly organized online.

Stages of work. Creating a drawing

Perhaps the most important department of the plant is the design center, where various designs are developed, which then appear on the wallpaper. The artist prints out a new print on paper and then assigns it a numerical code or a specific name. The finished sketch is discussed by experts and, if approved, is transferred to software engineers.

They, in turn, modify the image and bring it into compliance with the requirements of state standards. Then the drawing is sent to colorists who select a color palette. Wallpaper production begins when the image is completely formed.

Raw materials

Raw materials for wallpaper production must meet technical specifications. It is supplied in rolls, the width of which is 620 or 550 millimeters. Maximum deviations of no more than two millimeters are allowed. When made to order, the width of the rolls may be different. The diameter is usually 700-900 millimeters.

Paper is made from bleached hardwood or softwood pulp. It must have the same thickness, uniform and tight winding, clean and even cut edges at the ends. Stripes, folds, tears, and stains on the surface are not allowed. As a rule, raw materials from foreign manufacturers are used to make expensive wallpaper (one ton of paper costs 30 thousand rubles on average), while budget coverings are made from domestic materials. The list of necessary raw materials also includes paints, polymer pastes, and varnishes.

Printing a drawing

First, embossing rolls, in other words, printing forms, are installed on the equipment. Rolls of paper are also placed there. Each roller is dipped in its own ink and printed with its own color. Wallpaper production is controlled by both the computer and the printers.

You cannot mix paints, otherwise the image will simply float. If the technology allows for this, foam paint is also applied to the paper base. The fabric is then dried at high temperature. As a result, the paint foams and a relief is formed. Often wallpaper is also coated with a waterproof compound, which then creates a washable canvas. The relief of the pattern is given by the embossing unit.

After all the above activities, the material is delivered to a special workshop, where the individual webs are glued together. Wallpaper samples are then sent to the quality control department. The fabric is tested for strength, abrasion resistance, and so on. The material that has passed the test is dried, rolled, packaged and sent to the warehouse.

Production of 3D photo wallpaper

When drawing up a business plan for the production of photo wallpapers, it is necessary to take into account that in order to print simple and three-dimensional photo wallpapers, you will need a large-format printer that supports the 3D effect function. Financial investments when organizing an enterprise:

- acquisition or rental of industrial and commercial premises;

- purchasing a large format printer;

- purchasing a computer used to create high-quality images;

- paint and paper.

There are two types of 3D photo wallpaper for walls:

- images made on a single sheet of a certain format;

- panoramic pictures used to decorate a wall or the entire room.

Is such a business profitable?

Without a doubt, wallpaper production is an expensive and large-scale undertaking. Therefore, many entrepreneurs planning to engage in such activities are concerned about the question of whether their investment will pay off. This question cannot be answered unequivocally, because it is quite difficult to assess the prospects in this matter for several years ahead. The wallpaper market is unstable - periods of growth in consumer demand are followed by periods of decline.

But overall, the demand for wallpaper is predicted to increase. People still prefer traditional finishing materials to more expensive options. Thus, this market segment is still promising for investment. The product will be in even greater demand if you offer products of good quality and original design at competitive prices.

Selection of premises and equipment

A spacious department in a large construction supermarket or a regular store in a busy place will do. Plan not only a sales hall, but also an exhibition area so that the buyer can make a choice and see a clear demonstration of his purchase. You will need storage space, as well as space for the administrator and accountant.

To equip the store you will need the following equipment:

- several shelving options;

- glazed and open showcases;

- furniture for staff.