Flour production as a business

The production of flour products is considered an off-season business. This means that these products are in demand at any time of the year. In Russia, as in any other country, flour products are one of the most popular goods, so flour producers usually do not experience a shortage of buyers.

The main obstacle that can stand in the way of a novice entrepreneur is many competitors. In view of this, it is necessary to produce products of high quality. This is the only way to achieve success in this area.

Clean economy in numbers

Selecting a premises for production, its disinfection and cleaning, installation of a ventilation system and insecticidal measures are an important part of the costs of starting a business. In addition, such production will require a lot of permits from various supervisory organizations. It won’t be a big mistake if you need to plan expenses for all of the above in the amount of up to 300,000 rubles.

If 100 kilograms of a high-quality product are produced per hour of operation of flour production plants, then the first purchase batch of raw materials will require at least 200,000 rubles.

A round sum of 100,000 rubles will be required for installation and commissioning of plant equipment. To this we must add the cost of equipment for the mini-plant itself, which is 1,500,000 rubles. It turns out that you will initially have to invest at least 2,000,000 rubles. But within a month of the enterprise’s operation, a profit of 200,000 rubles will be received from the sale of goods. It turns out that within a year of operation the enterprise can recoup all costs and reach a profitable operating mode.

But only with a conscientious attitude to production, without reducing technological requirements and avoiding unjustified economic measures, will it be possible to consistently obtain high-quality flour and maintain your trade contracts with partners. And there will definitely come a time when there will be insufficient production scale to satisfy all available orders. Then you will have to think about expanding your business. And this will give a new level of profit and success.

Varieties and types of flour

Flour products can be made from:

- wheat. The most common. Makes up seventy percent of the total volume of flour produced in the Russian Federation;

- rye. Not as popular as wheat products. Rye grains are frost-resistant, so they were used more often in the past;

- corn. It is considered the “youngest”. Came to Russia from the USA;

- buckwheat Used for preparing oriental dishes, as well as for people on a diet;

- oats. Common, used by confectioners;

- rice Popular in Southeast Asian countries and China. It is nutritious, but provokes metabolic disorders and leads to a lack of vitamins;

- flax Used for treatment. Fatty, very healthy, expensive;

- soy. Rich in protein elements, nutritious, often used for preparing Asian dishes. It is becoming more common in the Russian Federation;

- peas It is a Russian alternative to soy products.

Kinds

On store shelves you can find flour made from various types of raw materials. To obtain the product the following are used:

- Wheat . Indispensable for the production of bakery products, pasta and other products. It accounts for 70% of the volume of flour produced in the Russian Federation.

- Rye . Rich in amino acids, vitamins, microelements. It is used for the production of culinary and bakery products, nutritional mixtures.

- Corn . Rich in starch, carotene, iron, vitamins PP, E, D, B1. It is distinguished by nutritional value, excellent taste and medicinal properties.

- Barley . It has a rich mineral composition. It normalizes the functioning of the digestive tract, promotes the elimination of toxins, and therefore is often used as a nutritional supplement.

- Buckwheat . Easily digestible, has dietary properties. An excellent option for preparing porridges and culinary pastries.

- Oats . Flour is in demand in the confectionery industry and as a food additive. Contains many carbohydrates, nutrients, vitamins A, B, E.

- Rice . A dietary product rich in starch, vitamins, and microelements. Used for preparing infant formula, sauces, and breading of fish and meat dishes.

- Linen . Used for medicinal purposes.

- Soy . The product is nutritious and rich in protein. It is a component of many Asian dishes.

- Peas . Used as an alternative to the Asian counterpart.

Flour making technology

Wheat flour production

The production process consists of several stages:

- The grains are cleaned and conditioned. All dirt is removed from the grain shells (dry/wet method). The procedure is repeated the required number of times.

- The raw materials are processed hydrothermally.

- The grain is ground into flour, the grinding products are sifted.

The production process is quite simple, the main thing is to use high-quality raw materials.

Production of rye flour

Rye grains, unlike wheat grains, contain many shells and aleurones. The membranes are tightly attached to the endosperm. When the grains are crushed, sprouts appear. In view of this, sorting is carried out by size, each group is ground separately from the rest. With two-grade grinding, sifted and peeled flour is formed, with single-grade grinding, one of them is formed.

Whole grain flour production

The peculiarity of the manufacture of such a product is that the grains are ground only once. As a result, the shells and germs end up in the finished product.

Whole grain products are considered healthier than regular grains, but they spoil quickly. In addition, various insects often live in it.

Production of other types of flour

The production of flour from rice, buckwheat, and oats is practically no different from the production of wheat and rye flour products. The only thing you need to worry about is who you will sell the products to. Such types of flour are not yet very common in the Russian Federation (except, perhaps, oatmeal).

We recommend reading:

- how to open your own bakery (business plan)

- how to open a dumpling production (business plan)

- pizzeria business plan

Flour milling production line

Category: Manufacturing equipment

Characteristics of products, raw materials and semi-finished products.

Flour is a product of grinding bread grains of wheat or rye. The properties of flour primarily depend on the chemical composition and structure of the endosperm of the grain - the place where nutrients are deposited. Its bulk consists of natural polymers - starch and proteins. Their total content in wheat grain is about 85% on a dry matter basis. The structure of the grain endosperm determines the characteristics of the flour produced.

There are three types of wheat: soft, soft vitreous and hard (durum). The endosperm tissues of soft wheat grains have a powdery, opaque structure consisting of small starch grains enclosed in thin layers of protein substances. Baking flour is produced from such grains. The endosperm cells of glassy, durum wheat are surrounded by thick, amorphous layers of proteins that give them transparency. Compared to mealy grains, glassy grains have greater density, absolute mass and strength. They are used to produce flour (in the form of grits or semi-grains) for pasta.

Depending on the quality, flour is divided into wallpaper, premium, first or second grade, as well as semolina. Wallpaper flour is produced from unseeded flour and contains crushed particles of the grain endosperm and outer shell (bran). Varietal flour is produced from sifted flour. Each type of flour is regulated by the corresponding characteristics of the properties of flour: color, ash content, grinding size and amount of raw gluten.

The quality of flour significantly depends on the content of shell particles in it - bran. The main structural components of the shell are fiber and ash elements (silicon, phosphorus, potassium, etc.). Therefore, the ash content of flour is an indirect characteristic of the amount of bran. In general, it is believed that the lower the ash content of flour, the less bran it contains and the higher quality it is.

The intermediate products of grain grinding are grains of various sizes. The grains of pure grain endosperm are a high-quality product: grains of baking flour, grains and semi-grains of pasta flour or semolina. During varietal grinding, the grain, which has a shell on its surface, is subject to further processing in order to remove the shell.

Features of production and consumption of finished products. Flour mills are usually located in places where products are consumed. The essence of flour milling is the grinding of grain and the separation of its component parts: shells, endosperm and germ.

Cereal grain has a complex, hard, dense and durable amorphous-crystalline structure with different strength characteristics of its constituent parts. Therefore, for grain processing, various machines and devices are used that exert mechanical and hydrothermal effects on the grain and the products of its destruction.

The outer surface of the grain is cleaned of adhering dust, the beards are separated and the fruit shells and embryos are partially removed using wallpapering and brushing machines. In entolentors, grain and its grinding products are subjected to sterilization by impact. As a result, living pests are destroyed, grains with larvae are destroyed, and the larvae mostly die.

During varietal grain grinding, the quality of flour is increased by hydrothermal treatment. As a result of this effect, the bonds between the endosperm and the membranes are weakened; the structure of the shells changes from a brittle state to a plastic-ductile state. All this together facilitates the separation of the fruit and seed shells of the grain with minimal loss of endosperm. In addition, the baking qualities of flour are improved due to the effect of heat on the protein complex of moistened grains. At many stages of flour-grinding production, metallomagnetic impurities are removed from grain and its grinding products.

The grain is crushed by two parallel cylindrical rollers rotating towards each other at different speeds. Typically, threaded grinding rollers are used, on the surface of which grooves are applied. The profile, slope, number and relative position of the grooves are selected depending on the required grind size and the strength characteristics of the crushed grain. They must provide the maximum amount of grains of various sizes with a minimum yield of powdered flour. The grain particles, on the surface of which the shell is preserved, are additionally subjected to grinding - repeated mechanical action of the working parts of grinding machines on the product through intense friction of the particles against each other and against the working surfaces of the machine. When grinding, shell particles are removed from the surface of the grains.

A significant place in flour-grinding production is occupied by the processes of separating grain grinding products. First, they are sieved and separated into several fractions that differ in particle size. Then the fractions are sorted by quality, i.e. divided into particles consisting of pure endosperm, and particles in the form of endosperm-shell intergrowths. This operation is called the enrichment of cereals and duns (products intermediate in size between cereals and flour). For enrichment, sieve machines are used that sort bulk mixtures according to the geometric and aerodynamic characteristics of the particles. In these machines, sieves are used for sorting by geometric characteristics (size), and air flows are used for aerodynamic (mainly windage) characteristics.

After sorting, the grains and duns are subjected to further grinding on grinding roller machines. The parameters of the working parts of the machines and their operating modes depend on the size of the crushed particles.

The strength of the grain shell significantly exceeds the strength of the endosperm, therefore, during varietal grinding, shock effects are used to separate the grinding products. The grinding products are additionally crushed in fast-rotating pin and whip rotors of entolators and detachers. At the last stages of the fraying and grinding processes, grinding is carried out in whip and brush machines. In them, the original product is subjected to impact and abrasion, as a result of which the molecular adhesion forces between the endosperm and the shell are disrupted. The endosperm (in the form of flour) is separated from the bran particles with minimal crushing.

The formation of finished products - flour - according to grades is carried out by weight dosing and mixing of product flows from individual stages of the technological process. Products are packaged in transport containers—fabric bags or in consumer packaging—paper bags.

Stages of the technological process.

The processing of cereals into flour can be divided into the following stages:

- purification of grain from impurities and separation of by-products - feed grain products;

— grain surface treatment using dry or wet methods;

— hydrothermal treatment (cold or high-speed thermal conditioning) of grain during varietal grinding;

— torn (crumb-forming) grain grinding;

— grinding of large and medium grains;

— grinding of products of coarse formation and grinding;

— grinding out the waste products of grit formation and grinding;

— formation and control of finished products.

Characteristics of equipment complexes.

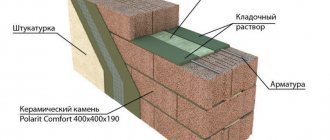

The line begins with a complex of equipment for preparing grain for grinding, which includes silos, control and transport devices for storing and forming grinding batches of grain; machines and apparatus for separating impurities that differ from grain in geometric dimensions, shape, density, magnetic and other properties; machines and apparatus for hydrothermal and mechanical treatment of grain surfaces; devices for dosing and quality control of grain.

The line includes 4...5 cereal-forming (torn) equipment complexes, each of which contains magnetic separators, roller machines, sifters and sieve machines. As the technological process progresses from the first to the last complex, the size of the processed particles decreases. Small fractions of crushed products are subjected to grinding in whip and brush machines.

The leading ones are 9...12 grinding equipment complexes, including magnetic separators, roller machines, detachers (or entolators) and sievers. The first, second and third complexes along the technological process are designed to produce premium flour. In complexes from the fourth to the sixth, premium and first grade flour is obtained. Subsequent sets of grinding equipment ensure the production of first and second grade flour.

The final complex includes equipment for weight dosing and mixing of group flows (components of flour varieties), containers for storing finished products, weighing devices and packaging machines.

In Fig. shows one of the options for the machine and hardware diagram of a flour milling production line for high-quality wheat grinding.

Rice. Machinery and hardware diagram of a flour milling production line

Design and operating principle of the line.

Pre-cleaned grain is supplied from the elevator to the flour mill by chain conveyors 1 and loaded into silos 2. The silos are equipped with upper and lower level sensors, which are connected to a central control point. Grain from each silo is released through gravity pipes equipped with electro-pneumatic grain flow regulators 3. Using regulators and a screw conveyor 4, grinding batches of grain are formed in accordance with the given recipe and productivity.

Each grain flow passes through magnetic separators 5, a grain heater 6 (in the cold season) and an automatic weighing dispenser 7. Next, the grain is subjected to multi-stage purification from impurities. In the grain cleaning separator 8, large, small and light impurities are separated. In the stone separating machine 9, mineral impurities are released. Then the grain is cleaned in disc triers: doll separator 10 and oat separator 11, as well as in a magnetic separator. The outer surface of the grain is cleaned in a vertical beaker 12, and aspiration residues are separated using an air separator 13.

Next, the grain through a magnetic separator enters the wet peeling machine 14 and after hydroprocessing by a system of screw conveyors 15 and 17, the grain is distributed into silos 18 for dehumidification. The silos are equipped with grain level sensors, which are connected to a central control center. The system for distributing grain into resting silos provides the necessary refrigeration modes with different durations and division of flows depending on the glassiness and initial moisture content of the grain. After the main humidification and defoliation, it is possible to repeat these operations through the humidifying apparatus 16 and the screw conveyor 17.

After defoliation, the grain, through a flow regulator, a screw conveyor 19 and a magnetic apparatus, enters the beaker 20 for surface treatment. From this machine, the grain passes through a magnetic apparatus into the entolator-sterilizer 21, and then into the air separator 22 to separate light impurities. Then, through a magnetic apparatus, it is fed into the humidifying apparatus 23 and hopper 24 for short-term dehydration. Then the grain is weighed on an automatic weighing dispenser 25 and sent through a magnetic apparatus for grinding into the first torn system.

Each torn system includes roller machines 26, sieves of torn systems 27, sorting sieves 28 and sieve machines 29. Sorting of products of grinding of torn systems is carried out sequentially in two stages with the production of large and partially medium grains at the first stage, and medium and small ones at the second grains, dunsts and flour. In sieve machines 29 the grains and duns of the I, II and III torn systems and the grains of the grinding process are enriched.

Coarse and medium grains of 7, 77 and 777 torn systems are processed in grinding roller machines 30 after they are enriched in sieve machines 29. The upper discharges from the screens of sifters 777 and IV torn systems are sent to whip grinding machines 37, the passage of the latter is processed in centrifugals 38. The grinding process uses two-stage grinding. After the roller machines 30 and 33, detachers 31 and 35 are installed to destroy conglomerates of intermediate grain grinding products and entolators 34 to sterilize these products by impact.

In sifters 32, 36 and 39, flour is sown from the grinding products, which enters a screw conveyor 40. From it, flour is fed into sieves 41 for control to ensure the separation of foreign particles and the required grinding size. Next, the flour is distributed through a magnetic device, an entolator 42 and a weighing dispenser 43 into functional silos 44. From these, the finished flour is supplied in bulk to road and rail transport, or using a weighing device 45, the flour is packed into bags, which are also transferred to transport for shipment by a conveyor 46 to flour consuming enterprises. Before packaging into consumer containers, the flour is pre-sifted using a sifter 47 and packed into paper bags on a filling machine 48. The flour bags are grouped into blocks, which are wrapped in polymer film on a group packaging machine 49. The resulting blocks from the flour bags are transferred for transportation to trading network.

Necessary equipment for flour production

The production line includes three groups of equipment. Each of them is used at some stage of flour production.

The initial complex includes equipment used to prepare raw materials for processing:

- Silos.

- Chain/belt conveyor.

- Devices for removing foreign particles.

- Devices for hydrothermal processing of raw materials.

- Devices through which grain quality is checked and dosing is carried out.

The main complex includes:

- Crushing devices.

- Magnetic separators.

- Roller machines.

- Screening devices.

- Devices for processing large particles.

The main complex may include a different number of units.

The final complex includes scales for the manufactured product, dispensers, and mixing devices. It is not recommended to save money on filling machines that sew bags. Their price is twenty to thirty thousand rubles. You will also need a truck and forklift.

Production equipment

The following equipment is used to produce flour:

- equipment for preparing grain for crushing;

- mill complex;

- packaging unit.

Equipment for the production of flour is supplied in complexes that are ready for production immediately after installation and commissioning.

The main suppliers of production equipment are the factories MILLTECH from Turkey, SKIOLD in Denmark, and OJSC Penzmash in Russia.

How to organize a flour production plant

In order to organize production, you will need a large area (at least two hundred square meters). It is necessary to allocate places for storing the finished product and storing raw materials.

It is necessary to choose a premises, taking into account the distance from it to grain sellers. The best option is near the elevator. It is advisable to purchase the premises. If there is not enough money to purchase, you need to draw up a lease agreement.

Grain must be laboratory tested before being put into production. You can use the services of a special company, but it is easier to hire a qualified employee.

To work in a grain warehouse, you need at least two storekeepers and a couple of loaders.

One shift in the workshop should include an operator and two workers. The production technologist controls the production. The service technician monitors the functionality of the equipment. You also need to hire a truck driver.

The premises must be securely guarded. Install video cameras and alarm system. Hire watchmen.

The accountant must be hired on a permanent basis. At first, the entrepreneur himself can look for clients. When the company begins to generate stable income, a customer relationship manager will be required.

Transportation and preparation of raw materials

Grain is delivered in railway cars. The railway tracks go directly into the territory of the flour mill.

Transportation of flour is possible by all types of transport

Grain wagons are different from regular freight wagons. They have a cone shape and several hatches at the bottom.

The locomotive brings the cars onto the track section, which is located above the receiving bunker equipment. The hatches open and the contents are poured into the bunker. From the bunker, along an underground conveyor, the grain is transferred to the upper floor of the elevator and placed in a storage tank.

A sample of each batch of raw materials is then sent to a laboratory for testing. Laboratory workers research and determine the possibility of using grain to produce flour.

The samples under study are checked for the presence of grain pests. To do this, use equipment that has two sieves with different cell diameters. During sifting, microparticles pass through the sieve and fall into the pan as sediment.

Then the samples under study are checked for contamination with impurities of other crops. After laboratory tests are completed, the batch of grain is sent to the mill.

A modern mill complex is a powerful equipment several floors high.

The grain begins its journey from the very top of the production structure and is transferred from floor to floor, passing through all stages of production. From the starting point to the finished product, the production process goes through all floors from top to bottom.

Raw materials arrive at elevator equipment from different fields and have different characteristics. To produce flour of the required quality, grain from different batches is mixed in the required proportion.

Permits and licenses for organizing a flour milling business

You can register as an individual entrepreneur. However, if you intend to engage in large-scale production, it is advisable to register the enterprise as a legal entity. Permission to start production is issued by the fire inspectorate, SES, and administration.

Permission to process grains and licenses are issued by Rospotrebnadzor. First, its employees check equipment documents, certificates from raw material sellers, and documentation on the production process.

Type of flour

In modern food production, the following varieties are regulated:

- Extra (gritty) – 10–25%.

- Highest grade (baking) – 25–50%.

- First grade (universal) – 25–70%.

- Second grade (butter) – 70–85%.

- Wallpaper – 95% or more.

Flour normalizes metabolism, regulates digestion, removes toxins, strengthens muscles, prevents diathesis and dysbacteriosis.

An adult needs from 300 to 500 grams of bread per day. During heavy physical activity, this norm increases to 700 grams. For children and adolescents, the daily dose of bread consumption is 150–400 grams.

Search for product sales channels

Buy flour:

- bakeries;

- confectionery;

- cafes, restaurants;

- supermarkets;

- wholesale bases.

Present the management of these enterprises with a profitable commercial offer. Actively participate in relevant exhibitions and forums.

Create labels that are informative and attractive to customers. This way you will make your brand recognizable.

Large production of wheat flour

There are different types of flour: rye, oatmeal, corn, barley, rice. But wheat flour is more popular in Russia. In order to become successful in this field and open a large manufacturing workshop, it is important to cooperate with good suppliers of raw materials. The performance of future flour depends on the quality of the grain. In addition to suppliers, you should take care of high-tech equipment. After all, a large enterprise must operate around the clock, therefore, the equipment must be durable, productive and automated (if possible). You need to understand that it takes a lot of money and a lot of effort to promote a large workshop.

Raw materials for production

To make flour, soft wheat is purchased. This is if it means producing bread flour. For example, for pasta products, hard grains are used.

When choosing raw materials, you need to focus on its grade. There are several of them:

- strong: this variety produces high-quality baked goods. The dough made from it is distinguished by its elasticity, elasticity, and fluffiness. Products made from this dough hold their shape well. Such wheat is sometimes mixed into low-quality grain to improve its characteristics. In this way, the quality of future flour is improved;

- medium: used for baking high-quality bread (according to GOST). This variety is also called valuable;

- weak: the name of the variety speaks for itself. It is used for subsorting. Bread only turns out good when combined with other types of grains.

To obtain good flour, you need to purchase grain of a strong or medium type. In extreme (very rare) cases, you can mix with a weak type. But it is not recommended to use it as the main raw material due to its low cost. You can ruin your reputation and “scare away” your wholesale customers.

Equipment for the production of

At first glance, it seems that you don’t need a lot of equipment - grind the grains, clean them and you’re done. In fact, to produce flour you need a large list of equipment:

- silos: containers for storing ground grains. They are tall flasks in the form of thermoses. A dry climate is maintained inside them to avoid spoilage of the ground raw materials. Flour filtration also takes place in silos. The units are equipped with hatches, ladders, and platforms for personnel control;

- wallpaper or brush: their functions are similar, so you can buy one. The devices intensively clean the surface of the grains from dirt, dust, and remaining tendrils. The shells are removed from the grains and the germs are removed. There are horizontal and vertical types of wrapping machines;

- sterilizers: disinfect raw materials. There are different types and shapes - square, rectangular, in the form of tunnels. Air sterilizers are used to sterilize grains;

- machines for hydrothermal processing of grains: necessary for washing raw materials. They come in the form of baths or flasks with built-in cleaning technologies. Divided by partitions into two sections - for initial washing and final washing;

- drying devices: continuously operating units - grain dryers. They are mobile and stationary. Drum, pneumatic and chess. Factories use stationary drum dryers;

- mills: for grinding prepared grains. This is a large-sized, automated technique. Looks like a big barrel with an engine. There are round or square mills. Built inside are strong millstones for grinding. The product is poured into a special container and the device is turned on, starting the grinding process;

- sifting devices: filter and sift the finished flour. These are large cone-shaped baths with ladders and a bag tipping system;

- packaging equipment: ready-made flour is placed in it in scattered form, and it comes out in bags. Special bags are placed in a tray;

- packages for packaging. You can make them yourself, but for this you will also need to buy a unit. Most factories purchase ready-made bags or order them with individual labels.

Production technology

If suppliers deliver grain in unprocessed form, it is adjusted to the standard at the plant itself. Sometimes this option is cheaper. Since cleaned, polished and washed grain is expensive even when purchased in bulk. But, on the other hand, all of the above equipment is required to process raw materials. Therefore, everything needs to be calculated and the results compared in advance. Let's consider the technology for making flour from unprocessed grain.

- Wheat is cleaned of dust, dirt and impurities using wallpaper or brush machines.

- Then hydrothermal treatment is carried out: washing and cleaning of the last unnecessary elements - shell, antennae, embryos.

- The finished raw materials are placed in a sterilizer.

- After these manipulations, the wheat is dried with a dry air stream.

- Grinding is carried out in mills. The unit independently pours the finished product into the provided tanks. From there the flour is transported to sifting equipment.

- The final stage is packaging. Most often, flour is packaged in bags of 1 or 2 kg. For wholesalers, packaging is carried out in plastic bags of 5 or 10 kg. Or in large bags of 25, 50 kg. capacity.

In large industries, product control is mandatory. Flour is taken for testing even before packaging. If the product complies with the standardization, its sale is permitted.

Profitability of flour production

Let's say a certain enterprise produces two tons of premium flour per shift. To organize production, purchase equipment and grain, you need about two million rubles. It is necessary to invest at least three hundred thousand rubles into the enterprise every month.

In 30 days, this enterprise produces 44-46 tons of product. If a kilogram of flour costs 18 rubles, then the income will be equal to 790 thousand. Subtracting current costs and expenses for the purchase of grain, it is possible to reach a net profit of 90-110 thousand rubles. If the enterprise operates smoothly and the product is sold stably, the production will pay for itself in 1-2 years.

Business Features

Of course, it is better to open such a business in rural areas, where you can purchase grain or grow it yourself without the extra costs of long transportation. Moreover, to start home flour production, you will need a separate room where you can freely place all the equipment. Organizing such activities in a city apartment is not only impractical, but simply impossible.

The first thing an entrepreneur should think about is not even technology or equipment, but sales markets. Very, very much will depend on who and where you plan to sell flour to, from production volumes to the type of flour. If you want to sell your product to, for example, a bakery, the main focus will be on high-grade wheat flour, while a small part of the production should be on lower grade flours (may be required for making healthy baked goods). In general, there are many different types and varieties of this product, which can be found below.

Classification of flour: types, types, varieties

The type of flour depends on the crop from which it is obtained. Flour can be made from wheat, barley, oats, rice, peas, buckwheat, soybeans, corn, and peas. Wheat and rye flour are most often used to make baked goods.

The type of flour will depend on its purpose. So, for example, wheat flour can be intended for making baked goods and pasta.

The grade of flour is determined by its quality, that is, the amount of the finished product obtained from grain. The greater this amount, the lower the grade (more shell gets into the flour, which makes it rougher). Premium flour is traditionally considered the most popular, but other varieties are also popular. Despite the fact that the highest quality product contains more protein, it lacks fiber and vitamins. Their presence in other varieties makes the raw materials attractive in the eyes of fans of a healthy lifestyle and those losing weight.

Calculation of business profitability

If you plan to sell flour at retail, then calculations of the profitability of such a business will look like this:

- Purchase of raw materials. The price of 1 ton of first class wheat is about $200;

- Sales The cost of 1 kilogram of flour is about 37 cents, the cost of bran (flour production waste) is about 8 cents.

- Calculation: from 1 ton of wheat, the flour yield will be 720 kilograms of flour and 280 kilograms of bran. All this can be realized for 280 dollars. The income from one ton of grain will be $280, and the profit will be $80. The average power of home production starts from 30 kilograms per hour, therefore, in a month you can grind about 7 tons of grain. With such volumes, the profit will be about $500 per month. Over time, you can purchase additional equipment, increase capacity and achieve higher performance.

Making flour at home

At home, flour products can be made using a special mini-mill. The procedure is as follows:

- A wholesale batch of 1st class raw materials is purchased.

- The grains are processed into flour.

- Flour products are sold.

- The bran is sold.

Twenty-eight percent bran is produced during the production of regular wheat flour.

Home production has certain advantages over industrial production. For example, there is no need to spend money on employee salaries. You can also produce a variety of types of flour products (rice, millet). A mini mill is a universal device capable of processing various types of grains.

Flour production on video

Necessary equipment

To start your own flour production, you will need the following equipment:

- Cleaning device. The main function of this machine is to separate grain from various impurities. The productivity of such equipment reaches 80 kilograms in 1 hour, and the cost is about $200.

- Sifter. This device allows you to separate the resulting cereal from the bran. The sifter's productivity is about 150 kilograms per hour, its weight is 32 kg, and its cost is about $300. Some manufacturers build a sifter into the mini-mill itself.

- Mini mill. Such equipment usually has the function of fine and coarse grinding. The cereal is crushed in the coarse grinding mode, then sifted, then passed through the grinder again, set to the fine grinding mode. The productivity of such a machine can be from 90 to 250 kilograms per hour, and the cost is about $500.

- Semi-automatic packaging machine. The cost of production equipment will be more than $1,000, but even with such funds, you are better off abandoning such a machine. Home production simply does not involve the production of such volumes of products for which this device is designed. A good alternative could be the same semi-automatic machine, but without a dispenser, which can easily be replaced by conventional electronic scales. The cost of such equipment is $700-600 lower.

- Polypropylene bags (500 pieces of 50 kilograms each cost about $85, and 5 kg bags cost about $50).

- Bag stitching machine. It's inexpensive, about $100, but it can significantly speed up the packaging process. You will also need to buy special threads.

- Small materials: spatulas, ordinary polypropylene bags (you may have customers who will purchase only 1-2 kilograms of flour).

How to start flour milling and organize the process

You can learn a lot of interesting and useful information on the forums of private flour millers. For example, a user with the nickname #KING_ZURALIA writes:

“Where the railway is 60-100 kilometers away along a dirt road, small mills are simply doomed to success. You can’t build a giant factory in the middle of nowhere. In addition, “big brother” loves wagon deliveries, so you won’t find big competitors further than 20 km from the rails. In short, consider the mileage: from the field to the mill it should be at least three to five times closer than by road to the railway.”

“Mills are a great business for the outback, where they have their own fields, although flour is transported along broken roads,” echoes his colleague [email protected]

Businessmen do not see any particular difficulties in organizing the work of flour mills, since almost all mills produced in Russia are reliable and have a high level of automation. Another advantage is that special products in case of repair will not be a headache for mechanics. Almost everywhere spare parts can be purchased quickly and cheaply.

INDUSTRIAL MILLS WITH STONE GRILLS

The SHELDEM company offers Austrian mills for industrial grinding of wheat, rye, amaranth, corn, buckwheat, barley, rice and other grain crops in order to obtain fresh natural whole grain flour. The mill body is made of hard wood, completely environmentally friendly materials. In high-capacity mills, pneumatic supply of wallpaper flour from the mill to the sieving machine is provided. The degree of grinding in all mills is adjustable. The mill wheel consists of a mixture of corundum and ceramics, or natural stone.

Freshly ground flour has many benefits. In addition to containing vitamins, freshly ground flour contains enzymes that affect the process of making bread and its quality. The rich fiber content of freshly ground flour (especially coarse flour) has a positive effect on human health, reducing the calorie content of bread and increasing the feeling of satiety.

For industrial mills, we additionally offer sifting machines that separate the ground flour into sifted flour - fine and completely without bran, peeled and wallpaper - coarser ground and with bran (especially a lot of bran in wallpaper). Industrial mills are divided into: free-standing mills without screening machine; mills with built-in sieving machine; mills with sieving machines and pneumatic flour feeding.

Financial indicators of the project

Investments and operating expenses

- rent for 3 months – 100 thousand rubles;

- purchase and installation of equipment – 1.5 million rubles;

- advertising expenses, paperwork – 80 thousand rubles;

- purchase of grain to start work - 200 thousand rubles.

Current expenses include:

- rent, utility bills – 100 thousand rubles;

- wages, taxes - 150 thousand rubles.

In some cases, transportation costs have to be taken into account.

Income and expected profit, profitability assessment

Statistics say that the profitability of the flour milling business is approximately 20-22%. It will be possible to recoup costs and start working profitably in 12-18 months with a work shift of 12 hours without stops and days off.

The greater the power and productivity of the machines, the more products can be produced per shift. Warehouses for raw materials and finished products must be designed to store a ten-day supply.

The flour milling business is interesting and relevant; by selecting a set of necessary equipment in a good price/quality ratio, you can organize a profitable production with relatively little cost.

ORGANIZATIONAL EVENTS WITHIN THE FRAMEWORK OF THE BUSINESS PLAN FOR FLOUR PRODUCTION

Before launching the main stages of a flour milling business plan, it is necessary to ensure the execution of all functional processes required for the normal functioning of the business.

- Determine the form of business and register your company in accordance with current legislation.

- Register with the tax and other government authorities, open a bank account.

- Select a suitable plot of land, analyze the possibility of growing your own raw materials and plan a complex of buildings and structures.

- Determine the composition of the production line for the full flour production .

- Calculate the number of personnel and their qualifications.

Staff

Flour production requires the formation of a staff of employees who would ensure the operation of the production line, carry out quality control at all stages of activity, keep records, report, guard, clean, carry out loading and unloading operations and manage freight transport.

A technologist will help the entrepreneur decide on the product range and select the necessary equipment model for it, develop documentation for obtaining permits to conduct activities. At the initial stage of business operation, its founder can assign this function to himself. The operator will control the operation of equipment from the production line. And an adjuster or mechanic will, if necessary, set up and repair it. If necessary, the staff should include an accountant, a security guard, a cleaner and a sales manager.

FINANCIAL AND ECONOMIC ANALYSIS

OPERATING COSTS FOR FLOUR PRODUCTION

In the process of flour production, you will be faced with the need to maintain it - since all operations require funding with cash. Therefore, the business plan for flour milling production must include the calculation of monthly costs. We list the main points for spending money:

- payment for a land plot - XXX rub.;

- rental payments or tax on buildings and structures – XXX rub.;

- utility bills - XXX rub.;

- fuel costs during the harvesting season - XXX rub.;

- repair of agricultural equipment and technological line – XXX rub.;

- transportation costs – XXX rub.;

- advertising and distribution – XXX rub.;

- wages to employees – XXX rub.;

- taxes, fees and other contributions to government bodies - XXX rub.

- other operating expenses – XXX rub.

The total cost of maintaining production will approximately amount to XXX rubles.

PROJECTING SALES REVENUE AND TOTAL PROFITABILITY

Income is 90% dependent on sales, so it is important that production volumes meet demand, and the product itself is sold in volumes sufficient to achieve payback within the target time frame. These processes in our flour production business plan will be influenced by the following factors:

- production cost;

- year-round production, due to the formation of reserves of raw materials during the growing season;

- active work with wholesale buyers and retail chains;

- product quality confirmed by independent tests.

The organization of flour milling production is planned for the following structure and sales volumes of finished products:

- First grade – XXX rub.:

- wholesale packaging of 50 kg – XXX rub.;

- retail packaging of 1 and 5 kg – XXX rub.

- Highest grade grade – XXX rub.:

- wholesale packaging of 50 kg – XXX rub.;

- retail packaging of 1 and 5 kg – XXX rub.

Following the described sales structure, the profitability of the enterprise will be XXX rubles. monthly.

WORKERS FOR ORGANIZING FLOUR GRINDING PRODUCTION

Flour production is a large-scale process associated with the agricultural work of growing grain, collecting, storing and processing it. It requires a large number of workers with varying levels of education and competencies. The business plan for flour milling describes the number of staff, specialization and level of material remuneration:

- production director - XXX rub.;

- chief agronomist - XXX rub.;

- senior mechanic or chief engineer – XXX rub.;

- food production technologist – XXX rub.;

- HR department – 3 people. – XXX rub.;

- accounting – 3 people – XXX rub.;

- shift foreman – 4 people. – XXX rub.;

- workers – 40 people. – XXX rub.;

- drivers – mechanics – 10 people. – XXX rub.;

- administrative and economic staff – 2 people. – XXX rub.;

- promotion and sales service – 6 people. – XXX rub.