Tiles and paving stones made from rubber crumbs are a low-cost and quite high quality products.

The material does not require expensive raw materials and a large amount of labor.

For manufacturing, it is enough to simply purchase several special machines and rent a small workshop.

Rubber paving slabs and paving stones are at the peak of popularity today. It is easy to sell not only at retail to individual companies and individuals, but also to sell in large quantities to trading enterprises .

In this article we will talk about the production technology of these products and give characteristics of the equipment.

Pros and cons of products

This product has many advantages. The crushed rubber tires from which it is made are high-quality material. For its manufacture, good synthetic rubber , expensive fillers and oils are used.

Advantages of crumbs made from such rubber:

- It is durable, “does not bend” under heavy weight, it can be laid in workshops, garages and car washes.

- It serves for a long time and faithfully up to 35-40 years, and at the same time does not wear out or “shed”.

- It is resistant to moisture, remains intact and dries quickly even after tropical downpours, which is why it is used in water parks and saunas.

- It is not afraid of sudden changes in temperature; it is not afraid of either severe frosts (up to -40) or sweltering heat (up to +50).

- Shoes do not slip on it - it is difficult to get injured on such tiles; “sports” surfaces are paved with it – tennis courts, playgrounds.

- The material is not damaged by aggressive substances; it is used to cover the floors of chemical laboratories.

- The tiles are easy and inexpensive to install and clean. It is used to pave stairs, entrances to buildings, shopping centers and many other “public” spaces with a large flow of people.

Also, paving slabs made from rubber crumbs can be given a wide variety of shapes, sizes and colors, and beautifully fit into the interior of the premises and landscape . It is placed in summer cottages and in elite cottage villages, on balconies and terraces.

Technology for manufacturing tiles and paving stones

Cold and hot pressing are the two most popular technologies used to produce tiles and paving stones today.

Hot way

Using hot manufacturing technology, tiles can be produced cheaply and quickly.

It should be borne in mind that such products are not durable and are “afraid” of severe frosts.

It is possible to find a buyer for such a product only in a temperate climate zone .

To perform hot pressing you need:

- First, give the raw materials the desired condition. To do this, in a special mixer it is necessary to create a continuous mass of crumbs and a binder - polyurethane glue.

- Distribute the mixture into molds and send it under a special volcanic hot press, which is heated by electricity or steam. He heats the mass and gives it the desired shape using pressure exceeding 5 tons. After such pressing, the material is ready - nothing else needs to be done with it.

The duration of the process and temperature depend on the thickness of the mixture:

- if this indicator is 8-15 mm, you need to press for 3-7 minutes at a temperature of +120-130 degrees;

- if 15-25 mm – 5-10 minutes. at +140-150;

- if 25-40 mm – 15-18 minutes. At +150;

- if 40-50 mm – 20 min. also at +150.

Cold way

“Cold” pressing is a more labor-intensive and expensive process. But it’s much more realistic to make good money on it, since “cold” tiles have all the above advantages.

To produce cold-pressed products, you must:

- Prepare raw materials. To do this, you need to do the same as in the case of hot pressing: create a continuous mixture from a polyurethane adhesive binder and crumb rubber. Plus add coloring matter. The important point is that much more glue will be required.

- Move this mixture into molds and send it to be pressed under 5 tons of pressure in a volcanic cold, unheated press.

- Next, the material is sent to a special chamber (heat cabinet) to dry at a temperature of +50-60 degrees. How long it stays there depends on the thickness. The thicker the material, the longer it takes to dry. On average, this process takes 5-7 hours.

- After heat treatment in a special chamber, the material is “completely dried” at normal room temperature.

The thickness of the crumb rubber fractions depends on how crushed the raw materials are. The finer the rubber, the finer the fraction. This thickness can vary by more than a hundred times - ranging from 0.1 mm to approximately 10-12 mm.

Thin fractions (up to 4 mm) are used to produce relatively expensive single-layer colored tiles, while thick ones are used to produce cheaper material consisting of several layers of the original black color.

The quality of “large” crumbs is lower because it contains unwanted impurities (“inclusions”) of metal or fabrics.

But it is also cheaper to produce for two reasons:

- firstly, it is not painted;

- secondly, to create a single-layer “solid” product, it is necessary that the adhesive binder completely envelops each individual chip.

Therefore, the larger the individual rubber particles, the less binder is needed to connect them.

The tile can also be “combined”, when the top layer of “quality” is thin, and the bottom layer is cheap and thicker. This material is usually about one and a half centimeters thick.

Components

For manufacturing you will need the following components:

- Directly crumb rubber. The tile consists of 80-90% of it.

- Polyurethane binding adhesive. It accounts for about 10% of the total size of the material. This glue not only binds the chips into a solid tile, but is also used to connect it to any surface.

- Dye. There is 5% of it in the tiles. Usually the coloring matter looks like a powder.

- Colored rubber granules. This substance is used to create patterns on the surface of the finished product and make it aesthetically pleasing. It is quite possible to do without this component.

Crumb rubber can be purchased at :

- special processing plants;

- enterprises producing rubber goods (rubber products). For them it is a by-product of production;

- factories that restore damaged tire treads. One of the waste products from this process is crumb rubber.

Equipment

For small production you will need:

- a volcanic press that can produce up to 100 m2 of products in 1 day. Its cost is around 300 - 400 thousand rubles;

- drying chamber (heat cabinet). Its price is 100,000 - 150,000 rubles;

- compression molds for crumb rubber – 40,000 rubles. each. You will need at least 3-4 of them;

- construction mixer (centrifuge type) – 120,000 – 220,000 rubles. You will need 2 of them.

Also, during production you cannot do without such equipment as:

- table (for molding) and platforms for mixers;

- carts for moving barrels of glue;

- a spatula to trim the mixture in the molds when laying;

- scales (electronic);

- specialist. a drill equipped with an attachment to mix the components;

Price of raw materials for the production of rubber tiles:

- 1 ton of black rubber crumb costs an average of 20,000 rubles;

- ton of colored – 25,000 – 40,000 rubles;

- 1 kg of polyurethane glue – 150 rubles;

- dyes – 8-10 rub. for 1 kg.

Electricity consumption will be approximately 15 kW/h.

You can purchase equipment from manufacturers such as Alfa-SPK, ECO-TOP, Alfa-MSK LLC, and intermediaries who deliver it from other countries (Far East Trans and others) at an affordable price .

Tile molds

Rubber tile molds can be purchased from the equipment manufacturers listed above. Common sizes : 550x550x55 (45) mm, 1100x1100x55 (45) mm.

How the described material is made

Typically, the production of rubber tiles begins with the processing of recyclable materials. Old tires can be shredded in two ways:

- Using mechanical crushing. To implement this, cutting machines are used. They are inexpensive, anyone can work with them, so the cost of producing raw materials is quite low.

- Using shock wave crushing. To carry it out, old car tires are placed in special chambers, then they are subjected to a certain effect, as a result of which crumbs are obtained. This process is fully automated and can be controlled by one person. Due to the high cost of installation, the cost of raw materials increases.

Note! Before sending the tires to the crusher, all metal parts are removed from the car tires, then they are cut into strips 5 cm wide. And only then the blanks are sent to the crusher, where they are cut into the sizes of the specified fractions.

Business plan

The production of rubber tiles from crumbs is not very expensive. To create a small plant, you will need approximately 1,200,000 rubles.

To ensure the production process you need:

- an area of approximately 120-130 m2 for a workshop and warehouses for storing raw materials and finished products;

- 3-4 workers for one shift;

- accountant and manager.

1 m2 of tiles can be sold for 1,700 rubles, and 100 tiles can be sold wholesale for 62,000 rubles.

The profitability of such production is quite high - around 20-40%, and if up to 35 m2 of products are produced per day, then the costs incurred will pay off in 4-6 months.

During this time, you can receive sales revenue of about 7.5 million rubles. (35·1700·21 days·6 months = 7,497 thousand rubles).

Monthly:

- Income 35·1700·21 days. = 1,249.5 thousand rubles.

- Expense 920 thousand rubles.

- Profit 1249.5-920 = 329.5

Profitability will be:

329,51249,5∙100%= 26,4%

By gradually developing your business and increasing productivity, you can achieve a higher level.

What are rubber tiles made of?

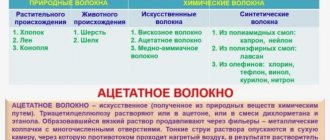

Rubber tiles are made from old rubber, such as old car tires and other things. But before starting work, the rubber must be specially crushed into small fractions.

The composition of the future paving stones includes:

- fine rubber fraction;

- polymer glue, which acts as an astringent;

- dyes that are designed to give the finished product the light that you need;

- Modifying additives: will help make paving stones strong and durable.

Is it possible to make tiles at home?

It is impossible to produce high-quality products that are manufactured using a cold method “at home”. But the “hot” cheap option is quite realistic .

To make rubber paving slabs with your own hands, large areas, money and time are not required - it will be enough to buy equipment such as a hot press, molds, and, of course, raw materials in the form of crumb rubber and other components.

If you buy the cheapest used equipment, then the starting investment will not exceed 200,000 - 250,000 rubles.

Thus, mini-production of slabs from crumb rubber with your own hands is possible even in the garage. Problems may begin later - at the sales stage. “Hot” tiles are a product with not a very good reputation, so there may be problems finding customers.

Process stages

The production of tiles from rubber crumbs involves several stages of work:

- At the preparatory stage, the production process consists of processing and preparing recyclable materials. Car tires are crushed to the required fraction by hand or using special equipment.

- Preparation of the mixture. The components necessary for the manufacture of rubber coating are loaded into construction mixers: rubber crumbs, polyurethane glue, coloring pigments, modifying fillers.

- Molding of products. The prepared and thoroughly mixed mixture is poured into molds.

- Then, using cold or hot pressing, the prepared raw materials are pressed in molds to the required density and thickness. In hot pressing, materials are baked at high temperatures.

- Baking. This stage will only occur when producing tiles using cold pressing. Its essence lies in the fact that prepared molds are installed in heating cabinets. In them, products are processed at low temperatures.

In order for the resulting products to have the required operational and technical characteristics, it is important to select the correct size of rubber crumbs and strictly follow the material manufacturing technology.

The resulting tiles are durable, strong and highly resistant to wear. Thanks to the porous structure, puddles do not form on the surface of such a coating, since after rain, water quickly seeps through the material and goes into the ground. The tiles are laid on any flat surface.