The Russian housing construction market is again moving towards stable growth - and it seems that even the experiment with the introduction of escrow accounts will not significantly affect its development. Thanks to this, the production and sale of fastening materials is becoming an increasingly promising business area.

Self-tapping screws are used both by private individuals during repairs and by large construction organizations. The production of self-tapping screws is a profitable business idea, the implementation of which will allow the entrepreneur to receive a stable income.

1. Application of self-tapping screws 2. Production technology 3. Investments 4. Registration 5. Preparing the premises 6. Equipment 7. Raw materials 8. Personnel 9. Ways of implementation 10. Payback calculation

Use of self-tapping screws

The official name of the self-tapping screw is self-tapping screw element. The material has a high fastening ability (due to the thread), which determines its popularity in the construction industry. There are many types of self-tapping screws: they differ in material and features of the structural elements (head, slot, end).

| Thread pitch | Application area | Diameter, mm | Lengths, mm |

| Average | Universal, for different types of fastening | 3.0; 3.5; 4.0; 4.5; 5.0; 6.0 | 12; 16; 20; 25; 30; 35: 40; 45; 50: 60: 70: 80: 90:100:120:140; 160; 180; 200; 220 |

| Frequent, carving in 2 passes | Metal sheets up to 0.9 mm thick without dowels. You need to drill a hole first | 3.0; 3.5; 4.0; 4.5; 5.0; 6.0; 8.0 | 12 — 200 |

| Rare | Soft materials without dowels (wood, plastic, plaster) | M | 16 — 150 |

| Medium, herringbone profile | Concrete, brick, hammered into dowel | 3.0; 3.5; 4.0; 4.5; 5.0; 6.0; 8.0 | 12 — 200 |

| Asymmetric | Elements of modern wooden furniture. Chipboards, plywood. You need to drill a hole with a diameter of 4.5 or 7 mm. | 5.0; 7.5 | 40 — 70 |

| Variable with notch | Concrete, brick, without dowels (dowels). It is screwed into a hole 15 mm longer than the self-tapping screw. | 7.5 | 70 — 200 |

Self-tapping screws are used to work with:

- metal products;

- wood products;

- plasterboard sheets;

- sandwich panels;

- window profiles.

Business registration

At the initial stage of organizing a business, an entrepreneur registers a company and indicates the codes of the activity that he intends to engage in.

Choice of legal form

For a small enterprise, a convenient form of doing business is opening an individual entrepreneur. In this case, it is much easier to maintain accounting records, and you can use one of the simplified regimes to pay taxes. Since this type of business has constant documented expenses for raw materials, it is beneficial to use the “Income minus expenses” mode, paying a tax of 15% on profits.

It should be borne in mind that if you want to expand sales channels at the expense of budgetary and state enterprises, such an organizational and legal form may not be enough. In the context of supply competitions, there is often a direct ban on working with individual entrepreneurs due to the latter’s lack of ability to work with VAT. In addition, the LLC (limited liability company) format gives purchasing managers much more confidence. The undoubted disadvantage of this format is the mandatory full maintenance of accounting records, as well as the payment of income and property taxes of the organization.

OKVED codes

The production of self-tapping screws belongs to group 25 of the new OKVED-2 classifier, mandatory for use from January 1, 2017.

| Code | Name |

| 25 | Production of finished metal products, except machinery and equipment |

| 25.9 | Manufacture of other fabricated metal products This class includes the manufacture of a variety of metal products, such as: cans and buckets, nails, bolts and nuts, metal household items, metal fastenings, ship screws and anchors, prefabricated fastenings for railway tracks and other miscellaneous products for use in households and industry. |

| 25.94 | Manufacturing of fasteners This grouping includes: • production of rivets, washers and other non-threaded products; • production of threaded fasteners such as bolts, screws, self-tapping screws and similar threaded products |

Particular attention should be paid to the fact that this OKVED falls under the tax holiday program in most regions of the Russian Federation. This means that a newly registered individual entrepreneur has the right to a 0% simplified tax rate for the first two years of his activity.

Market situation

The self-tapping screw business is directly related to the construction sector, since its participants are the main consumers of screws.

Due to the difficult international situation and problems in the economic sphere (domestic and global), the last few years have been marked by a crisis in many industries in Russia, including construction.

Now the situation is returning to normal. The construction market fully recovered by the end of 2020. According to data for the first quarter of 2018, 19.6% more apartments were commissioned compared to the same period in 2020. 72.5% more residential buildings were commissioned during this period. The general situation, the macroeconomic environment, indicates an increase in the consumption of building materials - that is, in favor of the business of producing self-tapping screws.

Registration of opening of activity

To open the production of self-tapping screws in the Russian Federation, you must first start preparing a set of documentation. If your plans are to create a large organization that will produce a wide range of products and involve the work of many hired employees, you should pay attention to opening an LLC. This approach will allow you to sell products through non-cash payments and sell them to legal entities, as well as create contractual relationships with suppliers of raw materials.

This type of activity is not subject to licensing, so you do not have to deal with any permitting paperwork. The only thing that awaits you on the way to opening a business is the need to undergo special certification. If you want to create a mini-production, you should register as an individual entrepreneur.

Premises and location of the enterprise

The success of a business is determined by the location in which it is located. Some companies are the most attractive to potential buyers in the sense that they can be reached without much difficulty, including by public transport. But this does not apply to this case. There is no need to rent a beautiful building in the central part of the city for your workshop. After all, this will not be a bakery or a snack bar, but a production facility. Since purchases of such products occur in tons, sales volumes will certainly not depend on the location of your premises.

Option for a garage room for the production of self-tapping screws

The most important requirement in our case is the availability of convenient access roads. After all, if the product is of high quality and does not need good advertising, the buyer will be ready to pick it up from absolutely anywhere, so when choosing a premises, it is necessary to take into account this particular criterion. Choose an inexpensive and convenient workshop that will meet the set of requirements for the production of self-tapping screws. For example, this could be a garage for large equipment. It will be convenient to use and will cost a small amount. All you need to do is remove all the debris from there, install lighting and start working.

Equipment and its wise choice

Once you decide on the premises, it is important to pay attention to the most expensive part of the project. These are machines for the production of self-tapping screws, which take up a lot of space in the room and have a considerable cost. Their selection and acquisition depends on which production method will be used in practice. The most common method is cold stamping, which involves the use of the following special technology.

- metal cutting depending on the product format;

- receipt of blanks into the carving hopper;

- sending “semi-finished products” to the furnace for the purpose of hardening;

- subsequent sterilization process.

There are a large number of machines on the market for the production of such products. Some of them can create about 50 units per minute, and some devices can create 300 screws.

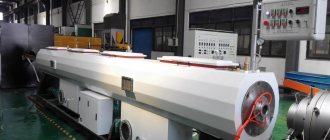

Self-tapping screw production line

Here it is necessary to competently approach the issue of product selection. It is logical that in the second case the production process will proceed faster, but the cost of such a machine will also be higher. But the device will pay for itself faster than a product that can produce only 50 pieces. However, the entrepreneur needs to choose, but experts advise not to spare money and purchase more productive equipment. Its cost will be about 600,000 rubles.

Service staff

One of the key advantages that manufacturing self-tapping screws has as a business activity is that there is no need to hire a large number of personnel. But, nevertheless, good equipment will require appropriate maintenance. An approximate calculation is as follows: 1 machine requires two workers, the average salary of each of them will be 20,000 rubles per month. You will also need to hire an accountant with a salary of 25,000 rubles. The equipment is difficult to operate, so employees will be required to undergo special preparatory measures. In addition, these specialists will have to monitor not only the condition of the equipment, but also the quality of the product in general.

Acquisition of raw materials

Raw materials for making self-tapping screws

To manufacture the product, you will need to purchase high-quality raw materials, which traditionally include brass and steel, supplied in the form of large coils. The cost of one ton of raw materials is 2,500 rubles; with this amount of material, about 500,000 finished products can be obtained. And the most important issue that is taken into account is the features of product sales. To resolve this issue, it is necessary to enter into a contractual relationship with a company or store. The main thing is that the manufacturer is focused on its own buyer.

Production technology

The process of manufacturing self-tapping screws is automated. The equipment is responsible for the entire production process. The required raw material is steel wire (rolled metal).

Let us describe the process of manufacturing products using the cold stamping method:

- We make preparations. We cut pieces of equal length from rolled metal (blanks).

- We form the caps and apply the carvings. In fact, you get ready-made self-tapping screws.

- The products are placed in an oven, where they are hardened to increase their strength.

- We wash the screws to eliminate interference during further processing.

- We spray anti-corrosion coating on clean screws.

The finished product becomes highly durable, capable of withstanding the negative effects of the environment for a long time.

Wire for the production of self-tapping screws

Any production requires optimal raw materials and technology. All types and varieties of fasteners are described by GOST, so the material of the product must comply with the technical parameters. The different characteristics of the metal allow us to produce a range of self-tapping screws with excellent parameters of strength, ductility and chemical composition. Wire for the production of self-tapping screws is in most cases used from high-carbon or stainless steel.

Wire for the production of self-tapping screws

When using machines for making self-tapping screws, it is important to consider the form factor of the supplied wire. The most preferred option is the bobbin type; such a device can easily be placed on a drawing machine without prior preparation. The chemical composition of the metal must meet many requirements; for metal screws, harder alloys are used, and for wood, ductile ones. The conditions for using the product are important, if construction work and fastening elements are located indoors, processing is carried out in a few simple steps and is not so important.

Investments

The main cost item for starting a business is the operating line for the production of screws, which operates automatically. Automation is more expensive, but more profitable in the long term. You don't have to hire a large staff.

| Expense item | Cost, rub. |

| Registration | 10 thousand |

| Premises for rent, 100 sq. m | 50 thousand |

| Equipment | 2 million |

| Raw materials, months norm | 150 thousand |

| Salary, 4 people. | 100 thousand |

| Additional expenses | 200 thousand |

| Total | 2.51 million |

The cost of renting premises is indicated subject to working in a city with a population of up to 500 thousand people. We rent premises that are ready for use and do not require major repairs. The costs of all preparatory work are included in additional costs.

Costs and profits

A quick return on investment is only possible if you have already established sales channels. An investment of 900,000 rubles will pay off in 10 months with an average profit of 90,000 rubles.

Start-up costs: approximate calculation for Krasnodar

| Expense item | Amount, ₽ |

| Business registration | 5’000 |

| Equipment | 800’000 |

| First batch of consumables | 70’000 |

| Unexpected expenses | 30’000 |

| Total | 900’000 |

Monthly costs

| Expense item | Amount, ₽ |

| Rental payments | 28’000 |

| Salary to employees | 152’000 |

| Consumables | 70’000 |

| Fare | 10’000 |

| Total | 260’000 |

Registration

A business producing self-tapping screws can be organized as an individual entrepreneur or a legal entity. However, LLC opens up great opportunities for selling products, allows you to increase sales, production capacity, and financial and economic indicators of the business.

Construction companies and large retail chains prefer to cooperate with legal entities. Working as an LLC, you can find regular large customers, develop stable sales channels and gain a foothold in the market.

An individual entrepreneur is much easier to register and maintain documentation.

A little about technology

Of course, the demand for construction products is constantly growing, and since self-tapping screws belong specifically to this group of products, starting a business in this niche is quite promising. It is strongly recommended to produce goods by cold stamping. This is due to the fact that in this way it is possible to achieve the most optimal technical parameters of the product. The technology itself is quite simple and is divided into 2 stages.

At the first stage, a blank is formed. In simple words, a blank. At this time, both the main part and the head with tip are manufactured. The next step is thread cutting using special tools that are installed on automatic machines. If you plan to gradually develop your business, then you can also add some equipment for the production of self-tapping screws. The technique will allow hardening to increase strength.

Preparing the premises

You need a room of about 100 square meters. m. There will be a production workshop with equipment, warehouses for raw materials and finished products, staff premises, and a place for loading/unloading goods.

The premises may be located on the outskirts of a populated area. It must be connected to the electrical network, a power cable (the equipment will consume a lot of energy), and must comply with fire and sanitary safety conditions and be connected to communications. An important condition is the availability of automobile access to the site.

Production premises should not be rented far from sales markets, since costs for fuel and fuels and lubricants increase unjustifiably. It is better to rent equipped empty space at a large enterprise.

Pre-project activities

Before you begin implementing a self-tapping screw production project , assess the degree of preparation of the organizational and legal components of your business.

Things to check:

- Is your company registered as a legal entity?

- Is she registered with the tax office and has a current account been opened?

- Has the location of the main workshops and office buildings been determined?

- Have negotiations been held with equipment suppliers?

- How mature is the job market in the region?

- What permits and licensing documentation will be required.

Equipment

The operating line for the production of screws consists of several machines:

- Drawing machine.

- Cold heading unit.

- Thread rolling machine.

- Tempering furnace.

- Galvanic bath.

- Drying centrifuge.

The drawing machine draws the wire, heats it, and cuts the blanks of the required size and diameter. The point and heads of the screws are formed on a cold heading machine. A thread of the specified size is cut on a thread rolling machine. The self-tapping screws are hardened in a hardening furnace. In a galvanic bath, an anti-corrosion coating and zinc anode are applied to them. The finished screws are dried in a centrifuge. Next, it remains to check the quality of the output material and package it. The cost of such a line according to the terms of the business plan is 2 million rubles. Productivity 180-200 pcs./min.

Basic issues of organizing production and commercial activities.

If you do not have your own funds, you must contact the bank for a loan. The bank will begin to consider your application only if you have a meaningful business plan, and will be able to issue a decent loan for organizing a business project. You cannot do without a detailed step-by-step description of the upcoming activity even in the case when the initial capital is already available and you just need to register a legal entity, this could be, for example, an individual entrepreneur (individual entrepreneur) or LLC.

The technology for manufacturing self-tapping screws is simple, but it should be scrupulously analyzed and carefully calculated in advance, before opening a company.

It resembles the production method of a regular nail. The difference between metal fasteners is that the rod has a head and an external thread.

Cold stamping method diagram:

- first, the raw material in the form of twisted wire is sawn crosswise into small bars of the required length;

- then the cap is formed and the thread is cut;

- a mandatory procedure is hardening the resulting screws in the oven;

- products are thoroughly washed;

- A special anti-corrosion coating is easily applied to a clean surface.

To organize production, it is necessary to purchase equipment. The operating line for the production of screws is fully automated:

- The automatic cold heading machine provides rhythmic drawing of wire. The chopped semi-finished products are pushed into a large box;

- The thread rolling mechanism is equipped with special dies that grind threads of a certain size;

- Hardening of finished self-tapping screws occurs in an oven where the temperature is 880-950 ˚C;

- A special galvanizing line consists of several adjacent baths. The screws are moved into a rotating drum, then immersed alternately in a bath with a degreasing composition, in a second container with phosphate, and in a third with oxides. At the final step, the parts are washed with running water. They are now ready to be coated with a layer of zinc;

- The finished screws are dried with a hot air stream in a conventional centrifuge.

The choice of high-quality equipment is a guarantee of uninterrupted production and delivery of finished metal products to the consumer.

Experts recommend purchasing machines and other compact equipment from well-known Taiwanese companies FOB, LianTeng. Their line design is functionally complete (modular), allowing independent stand-alone layout and intermediate diagnostics after each next action. You can buy a machine that produces 50 parts per minute, or you can buy a more expensive one that works at a speed of over 250 screws in the same time. The latest generations of computer-controlled self-tapping equipment are designed for different workpiece lengths and different thread pitches. They have wide possibilities for cutting alternating projections and depressions not only for ordinary screws and screws, even for dowels.

Cold heading machines of the YH1564, YH2076 brands have proven themselves well with an average productivity of 120 and 160 screws per minute. The machines are easy to maintain, they produce excellent quality products, and have a short payback period.

It is also profitable to start the production of self-tapping screws with Chinese semi-automatic machines INNOR and Candid.

In the Russian city of Samara, SAMSTAL LLC produces affordable machines for self-tapping screws of the same name of good quality. CJSC "Monolit", Moscow. LLC "Auto", Kazan. Technoservice Krasnaya Zarya LLC, St. Petersburg. The list of foreign and Russian manufacturers of machines for producing self-tapping screws can be continued for a long time. Many form an operating line from installations and mechanisms from different manufacturers.

Raw materials

The starting material is steel or brass wire. The material must be selected based on the final purpose of the screws. For example, screws from:

- stainless steel - used when working with wood;

- high-carbon steel - used where a high hardness coefficient is needed;

- brass - for finishing work.

We deliver spools of rolled metal wire to production. It is easy to get it in Russia. One reel produces approximately half a million self-tapping screws. It is better to purchase it directly from the manufacturer at wholesale prices. This will reduce costs.

Staff

The advantage of automation is that you don't have to hire many workers. After delivery, the manufacturer performs the initial setup of the machines. The craftsmen are left to monitor their work and ensure the continuity of the production process.

No more than two or three people will be required per shift. They must undergo special training and be able to operate machines. They can also be storekeepers, deliver raw materials to the workshop, store finished products, and load them into vehicles.

You will also need a driver with a car, an accountant (can be hired through outsourcing), a sales representative who will negotiate with networks and construction companies (the entrepreneur himself can take on this work at first).

Self-tapping screw manufacturing technology

The production of the product, as previously mentioned, does not require any qualifications; it is enough to load ordinary blanks into the machine and it will independently cut threads on them.

The machine is set up by the supplier at the time of installation..

As a result of this, at first even the businessman himself can participate in production; in the future, this will help him understand what can happen with such a machine and help him avoid problems with careless workers.

All that is needed for stable operation is good wiring, which has a low chance of fire.

Since production will take place on a large scale, the best solution is to have regular customers who are able to pick up all the goods within a certain period of time.

Ways of implementation

It is recommended to use all possible implementation paths:

- enter into long-term contracts with construction companies;

- work with specialized organizations (for example, for the production of windows, doors, furniture);

- sell products to construction stores and networks;

- interact with private contractors.

Think over your pricing policy. Reasonably low prices for quality products are an obvious way to gain loyal customers. It is also recommended to think through various promotions that encourage customers to buy more and more often.

Develop an assortment. Start producing and selling several varieties of self-tapping screws, identify those that are in demand and focus on them. Nails and anchors can be produced as additional products.

Necessary raw materials for production

The raw material for the production of self-tapping screws is steel wire or rods made of various types of steel. Certain GOST standards apply to various types of raw materials, in particular, raw materials for cold heading equipment fall under GOST 5663-79. This includes cold-headed wire in coils or coils.

Wire in coils - raw material for the production of self-tapping screws

They buy wire in bulk, in tons, from metal rolling companies. Central Russia has the lowest prices for steel, but high transportation costs due to the large weight of supplies.

| name of raw materials | Size | Price |

| Steel wire GOST 5663-79 | 3-6 mm | 60 thousand rubles/t |

| Low carbon steel wire GOST 17305-91 | 3-6 mm | 52 thousand rubles/t |

How to reduce raw material costs

When thinking about optimizing the cost of raw materials in the price of finished products, you should never skimp on their quality. Replacing high-strength steel with that used for the manufacture of household products will lead to the fact that the screw heads will twist at the slightest excess of torque.

The cost of raw materials is reduced by establishing direct contacts with suppliers, agreements on discounts on shipped volumes and a carefully thought-out logistics and storage scheme.

Payback calculation

Let's calculate the payback and profitability according to the business plan for self-tapping screws:

- The amount of initial investment is 2.51 million rubles.

- The total amount of expenses per month is 350 thousand rubles.

- An operating line with a capacity of 180 - 200 screws per minute in 1 shift (8 hours) within 22 days (month) will produce 1.9 - 2.1 million pieces. self-tapping screws With an average price of 1 screw - 25 kopecks, monthly revenue will be 475 - 525 thousand rubles.

- Minus monthly costs, net profit is 125-175 thousand rubles.

- You can reach the break-even point in 15-20 months.

It will be possible to fully recoup the initial costs in about 1.5 years. Then the entrepreneur will begin to receive a stable high income. However, such a forecast will come true only with constant production and marketing of manufactured products.

With proper organization of the production process, you will be able to create a business as strong as the profiles assembled using your screws. The business plan for the production of self-tapping screws presented in the article will help you better understand the features of manufacturing fastening tools, we will tell you about the main stages of creating a mini plant and the nuances important for achieving success.

What equipment to choose for such a business

If you are focused on producing only high-quality self-tapping screws, then you must immediately take a responsible approach to purchasing the necessary equipment. Try to immediately purchase not cheap Chinese equipment, but normal devices that can last for many years. First of all, pay attention to the operating speed of the machine, on which the speed of production of self-tapping screws will depend. Therefore, it is better to spend well right away rather than buy equipment several times.