Description

Global volumes of waste plastic, glass and rubber amount to millions of tons. Therefore, the need for enterprises for processing recyclable materials increases every year. The problem is that the equipment for this is expensive.

Treatment plants are even more expensive, without which the plant pollutes the environment with emissions no less than garbage. It is much easier and cheaper to open new landfills for waste disposal, especially in Russia with its vast expanses.

Experts believe that if you focus on small volumes of recycling, tire recycling activities can be economically profitable.

There are several options for tire recycling ideas:

- Grinding into crumbs. The resulting substance is used for the production of rubber tiles and automobile parts, for the substrate in road construction, for filling sports equipment, and for repairing bridges.

- Tire restoration. The worn tread is removed from the tires and a new one is applied. A cold or hot technological method is used. Natural resources are significantly saved, since to produce one tire “from scratch” you need 30 liters of oil, and when produced using the retread method - 5 liters.

- Pyrolysis. At very high temperatures, fuel, gas, carbon black and steel cord are obtained from tires. The technology is unstable, expensive and takes a long time to pay off.

- Complete destruction by burning. This releases energy that can be used in production.

The first two technologies are environmentally friendly; when using pyrolysis and combustion, harmful substances are released into the atmosphere. “Dirty” production will require lengthy and expensive coordination with environmental protection services, as well as the installation of special treatment facilities.

And given the relative innovation of tire retreading and the skeptical and wary attitude of consumers, your best bet is to get into the tire crumb business.

Pyrolysis plant for recycling tires into fuel

This method of recycling tires involves burning them in an airless space at a temperature of 500-1,000 degrees. As a result you can get:

- coke;

- gas;

- liquid fuel.

The metal cord remains intact and goes for further melting. The average yield of liquid fuel is 40% by weight of the raw material.

Tire recycling and burning equipment includes:

- Loading chamber;

- Combustion chamber;

- A condenser in which gas is converted into fuel.

The technology allows you to change the type of pyrolysis and ultimately obtain more gas or coal. This ensures waste-free and environmentally friendly production. The resulting gas is reused in the installation and no harmful substances are released into the atmosphere.

Chinese-made pyrolysis plants are popular. But they have significant disadvantages:

- instructions and documentation are often in Chinese, without translation;

- difficulty ordering spare parts;

- installation does not comply with the stated characteristics.

Business plan

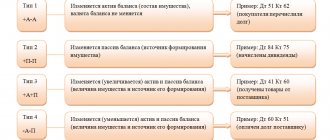

The implementation diagram looks like this:

- registering an enterprise and obtaining permits to operate;

- study of technology;

- production location planning;

- purchase of equipment;

- purchase of raw materials;

- hiring workers;

- sales of finished products;

- financial calculations.

When working with recyclable materials, competition is insignificant and you don’t have to do detailed market research. Numerous service stations and tire shops are stable suppliers of used tires, and with high construction rates there is always a demand for recycled products.

You can download a ready-made business plan for tire recycling using the link.

Market analysis for crumb rubber production

Most old tires are not recycled. In many cities there are no places for their storage and disposal. People throw a large number of used tires on the roadsides.

The problem is only getting worse due to the constant increase in the number of vehicles. As a result, the volume of tires subject to recycling is increasing. The country does not have a system for recycling old tires. There are very few tire recycling plants.

Tire recycling as a business may be of interest to entrepreneurs. There is a demand and need for crumb rubber, but competition is low. You can occupy a profitable niche in the market, because in most regions there are no tire recycling plants.

Registration and permissions

A tire recycling business can be registered as an individual entrepreneur (RUB 800) or a limited liability company (RUB 4,000).

Waste tires belong to waste hazard class 4 - low-hazard substances. To carry out activities for the collection, transportation, processing, disposal, neutralization, disposal of waste of classes 1-4, a license is required, issued by the Federal Service for Supervision of Natural Resources.

The validity period of the license is unlimited, the cost of obtaining is 7,500 rubles.

In addition to the license, it is necessary to obtain work permits from the Sanitation Station and the State Fire Supervision Authority.

Tire recycling equipment

We invite you to familiarize yourself with the types of equipment from the Eco Gold Standart company, which today is the leading manufacturer of tire recycling equipment on the Russian and CIS markets. The company produces two types of tire recycling lines: Eco Gold, Eco Gold Euro. Both lines are produced with a capacity of 400, 550, 700, 1400, 4000 kg per hour. However, the composition of the equipment is completely different. Let's take a closer look.

Composition of Eco Gold line equipment

Composition of Eco Gold line equipment:

- machine for cutting and processing tires “Guillotine”;

- hydraulic machine "DS-650";

- loading conveyor - 1;

- primary grinding apparatus Shredder KG - 2;

- Shredder grinding apparatus - 3;

- device for primary grinding - 14;

- belt separator - 4;

- collection cyclone - 5;

- Vibrating sieve - 8;

- Magnetic separator - 11;

- industrial electrical equipment - 12;

- Dust cyclone - 10;

- metal structures and gas ducts - 13;

- fans: transport and high pressure - 9;

- impact crusher - 7;

- vibrating sieve and dust cyclone - 6.

Composition of equipment of the Eco Gold Euro line:

- hydraulic machine "KV-700";

- cutting machine;

- loading conveyor;

Technical characteristics of EcoGold Euro tire recycling - installation for primary grinding;

- transport and high pressure fan;

- magnetic and belt separator;

- collection and dust cyclone;

- industrial electrical equipment;

- metal structures and gas ducts;

- impact crusher;

- vibrating sieve

Exclusively all types of equipment are fully automated and equipped with a high degree of protection against unexpected loads, improper operation and unstable high voltage.

Technology

The process of recycling tires by shredding occurs as follows:

- Collection of tires.

- Sorting and selection of recyclable tires. Removing thorns, nails and other foreign elements.

- Cutting tires into small pieces.

- Loading the material onto a conveyor and then into a special installation, where the rubber is crushed and the metal components of the tire are removed.

- From the shredder, the crumbs enter the rotary crusher, where they undergo another stage of grinding and purification from impurities.

- To obtain the purest possible rubber, the material is further processed in a separator.

- The crumbs are sorted into fractions on a vibrating sieve.

- To obtain an especially fine powder, the crumbs are passed through a grinder.

- Packaging of products ready for shipment.

For storage in a warehouse, it is necessary to ensure room temperature and dry air, since high humidity has a negative effect on the processed material.

In addition to crumb rubber, the recycling process leaves behind the textile component of tires and metal wire, which can be scrapped.

Instructions - how to make crumb rubber

Content:

Rubber crumb is one of the modern and fashionable materials that are used for laying playgrounds and paths, decorating adjacent areas and even roofs. And if you want all the work to be done carefully, efficiently and for a long time, then it is better to do it yourself.

To realize your idea, you can make crumb rubber at home and save money on buying ready-made material. This is exactly what we will tell you about in our article.

What to make crumb rubber from

There are two main options for making crumb rubber yourself:

- Use of car tires, tubes and other unnecessary rubber materials. Of course, in the process of grinding the selected materials (in particular, tires), some difficulties will arise. This is due to the fact that the raw material is difficult to grind; it contains metal cords that need to be removed. However, with scissors, cleavers, a knife and an ax available, you can begin the process of chopping resources.

- Use of any rubber materials. In this case, it is important to cool the raw materials to a temperature of minus 70-80 degrees Celsius. This will make the material brittle, brittle and grind it to the desired state. The output will be the same crumb, but the process itself is very labor-intensive and difficult to implement at home.

How to make crumbs at home

Having prepared a sufficient amount of raw materials and all the necessary tools, you can get down to business. It is important to remember that to create a coating of crumb rubber 1 cm thick and an area of 1 sq.m. you will need about 8 kg of rubber.

So, having prepared the required amount of rubber, you must begin removing unnecessary elements. This can be done with an ax or a sharp large knife.

After removing all metal particles from the tires, you need to:

- Cut the material into thin strips. Their thickness can vary from 0.5 to 1 cm. But the thinner the better.

- These strips need to be chopped transversely using scissors or a knife. The result should be small squares and diamonds that will look neat in the finished product.

The resulting raw material - crumbs - is completely ready for use. They can simply fill paths and areas on the playground, while simultaneously providing waterproofing. And the best part is that you created the material with your own hands and saved money from the family budget!

ekopol.kz

Room

A tire recycling business should not be located close to residential areas. It is best to rent part of a workshop from an industrial enterprise in an industrial zone. In this case, you will not have to deal with bringing the premises into compliance with fire and sanitary standards.

The size of the mini-factory should be approximately 300 square meters. m. to accommodate all the necessary equipment, a warehouse for raw materials, a warehouse for finished products and a change house for workers.

The premises must have proper communications - electricity, water supply, heat supply and sewerage.

Recycling

Rubber recycling allows you to extract rubber from waste tires. This can be done in several ways:

- Chemical. The most toxic and harmful to the environment.

- Mechanical. Tires are crushed and exposed to high temperatures.

It is the second option that is now used in tire recycling. It is very popular, but more expensive. Please note that recycling tires also produces metal waste. During processing, metal cords are separated from synthetic ones.

Now the number of vehicles is constantly growing. The amount of waste, including tires, is also increasing. There are still not enough enterprises for their processing in our country. If recycling is properly organized, recycling car tires can bring enormous income.

To make tire recycling profitable, you need to think through everything. Let's take a closer look at the organization of this business. You will need vehicles, because old tires will need to be collected and brought to the warehouse. There the metal parts are removed, and the rubber goes to cutting. Tires need to be cut into small pieces. For this purpose, the mini-factory has powerful scissors. The crushed tires are poured into the hopper of the factory reactor.

At high temperatures, the tires in the reactor decompose. Recycling car tires allows you to obtain a number of products at once:

- liquid fuel;

- gas;

- residue containing carbon;

- metal.

To support tire recycling, some of the gas is returned to the reactor. The rest of the gas enters a special pipe. In terms of volume, its quantity can be compared to the exhaust of a truck. The carbon residue is sifted to separate the steel cord.

After processing you will have a carbon residue, liquid fuel and steel cord. Rubber crumbs are purchased by many enterprises that manufacture rubber products. She is always in demand. Steel cord and liquid fuel are also in demand.

The peculiarity of tires is also their weight. Each one is quite heavy. Such large-scale waste becomes a good source of polymers. There are many of them even in small towns, so recycling of car tires will always be a popular service. The main thing is to establish the process itself and obtain all permissions.

And recycling car tires will save the environment from pollution, because tires naturally take hundreds of years to decompose.

Equipment

The most expensive part is purchasing equipment for production. To ensure an uninterrupted technological process, the following machines and devices will be required:

- equipment for removing the bead ring from the tire;

- tire cutting machine;

- devices for grinding rubber into crumbs of different fractions;

- conveyor for feeding material;

- magnetic separator – 2 pcs.;

- air separator;

- vibrating sieve for different degrees of crumb filtration - 2 pcs.;

- bunker for collecting crumbs;

- storage bin for metal wire;

- dust cleaner;

- electrical panel;

- loader.

In addition, you need to purchase:

- Containers for packaging crumb rubber.

- A vehicle if you plan to independently deliver products.

- Workwear and protective equipment for workers.

- Computer and office equipment for record keeping.

Making crumb rubber with your own hands at home

In recent years, the use of crumb rubber and materials made on its basis for decorating areas, organizing paths, and covering the roofs of houses has become fashionable. Crumb rubber can also be used to create waterproofing for building foundations. In order to use elements made from crumb rubber on your site, you can contact a company that professionally works with crumb rubber. However, working with this material is not so difficult. If you wish and have free time, you can make crumb rubber at home with your own hands.

What is DIY crumb rubber made from?

When solving this issue, you can go in two ways. Path number one relies on the transition of rubber to a brittle state at low temperatures. If at home it is possible to cool the source material for preparing crumbs to a temperature of -70 ... -80 degrees Celsius, then it will be possible to obtain crumbs from any type of source materials. However, solving this problem at home is not so easy.

Path number two is to competently select the source material. As we know, crumbs can be obtained from tires and tubes from car wheels. But tires are very difficult to grind under normal conditions, and it is also difficult to extract the metal cord from them later. For this reason, to obtain crumb rubber at home, it is better to use old worn-out tubes as raw materials. This material can be cut quite easily using improvised tools available in any home.

How to make crumb rubber at home?

At the initial stage, it is necessary to prepare a sufficient amount of raw materials, i.e. old car inner tubes and corresponding cutting tools. To make a coating with an area of one square meter and a thickness of 10 mm, about 8 kg of rubber crumb is required. When producing crumbs from old chambers, the loss of material by weight is minimal. Thus, it is necessary to prepare the starting material at the rate of 8 kg of old cameras per 1 square meter of coating.

To grind rubber, you can use ordinary scissors or an ax. If desired, you can build special guillotine shears. As a last resort, you can organize cutting of the cameras with a fairly sharp knife.

Making crumbs should be done according to the following algorithm:

- Remove all metal elements from the old camera

- Cut the camera into thin strips

- Grind the thin strips obtained in step 2

See also:

rezinovaja-kroshka.ru

Raw materials

Used car tires for recycling can be purchased:

- at tire service stations and service stations;

- at large motor transport enterprises;

- at a recycling collection point, or open your own waste tire collection points.

The big advantage of tire recycling as a business is that the cost of old tires is very low, sometimes you can get it for free, and in some cases you can earn money for recycling.

Revenue part

As a rule, the average price of 1 kg of crumb rubber from tires and tires is about 17 rubles. In parallel with this, one production line produces no more than 2100 tons of products per day. Consequently, the monthly income from the sale of the main product will be approximately 750 thousand rubles.

Technology for processing tires into crumbs

To the total amount of income should be added the amount from the sale of fuel oil - 375 thousand rubles. The total revenue will be 1,125,000 million rubles. per month, and net profit before tax will be 645 thousand rubles.

Hiring workers

Depending on the volume and schedule of work, production will require:

- Shift supervisor - 2 people.

- Equipment operators - 4 people.

- Loaders - 2 people.

- Driver – 1 person.

- Receiver at the tire collection point - 1 person.

- Product distributor - 1 person.

- Accountant - 1 person.

To save money, some of the functions of accounting, sales and general management can be taken over by the business owner.

Since the business is specific, and workers will have to deal with waste, the company will most likely have a high staff turnover.

Sales of products

The main consumers of the mini-plant are construction organizations and enterprises producing building materials. The list of manufactured products that include crumb rubber to improve technical characteristics is quite wide:

- roofing moisture-resistant coating;

- railway sleepers and gaskets;

- filler;

- shoe soles;

- road surface;

- paving slabs;

- fiber concrete;

- various rubber products.

Wire from tires obtained as a result of processing is handed over to scrap metal collection points.

Product cost and preliminary financial calculations

In order to open a mini plant for the production of crumb rubber, an entrepreneur will need to incur certain financial costs, which we propose to understand further. All data is taken as the average statistical indicators in this industry.

- Registration process – up to 150 thousand rubles.

- Rent – 180 thousand rubles.

- Repair work and arrangement of the workshop - 150 thousand rubles.

- Purchase of tanks for fuel oil – 80 thousand rubles.

- Production line - about 1,500,000 million rubles.

- Production tools – 200 thousand rubles.

Result: 2,260,000 million rubles.

Tire recycling schedule in Russia

In addition, to ensure a high-quality production process for processing tires and tires, the plant must pay the following monthly costs:

- Salary to employees is about 120 thousand rubles.

- Electricity and other communication systems – 30 thousand rubles.

- Costs for transportation and advertising campaign – 150 thousand rubles.

Result: 300 thousand rubles.

Financial calculations

The main initial investment in the idea of a processing business is the purchase of equipment. Manufacturing technology cannot be organized in a handicraft way, so a full set of machines is required to complete the production line.

The amount of capital investment consists of the following costs:

| № | Naming of expenditures | Amount, rub. |

| 1 | Registration costs and permits | 10 000 |

| 2 | Workshop rental (2 months) | 100 000 |

| 3 | Indoor renovation work | 60 000 |

| 4 | Purchase, installation and commissioning of equipment | 2 800 000 |

| 5 | Purchase of vehicles | 450 000 |

| 6 | Purchase of raw materials and supplies | 50 000 |

| 7 | Product promotion | 50 000 |

| 8 | other expenses | 30 000 |

| Total | 3 550 000 | |

The amount of monthly production costs is approximately equal to:

| № | Naming of expenditures | Amount, rub. |

| 1 | Workshop rental | 50 000 |

| 2 | Public utilities | 40 000 |

| 3 | Wage | 200 000 |

| 4 | Purchasing fuel | 25 000 |

| 5 | Purchase of raw materials and supplies | 50 000 |

| 6 | Repair of equipment | 30 000 |

| 7 | Administrative expenses | 20 000 |

| 8 | other expenses | 40 000 |

| Total | 455 000 | |

On average, the recycling line can recycle 3 tons of tires per day. From this amount of raw material, approximately 2 tons of crumb rubber and 800 kg of steel cord are obtained. The price of crumbs depends on the fraction, on average it is 17 rubles/kg. Scrap metal is accepted at 6.5 rubles/kg.

There is also additional income from accepting tires for recycling from delivery companies, at 1,500 rubles per ton. Presumably, this is 20% of the total volume of incoming tires.

The total monthly income of the mini-factory is:

| № | Source of income | Calculation | Amount, rub. |

| 1 | Rubber crumb | 2 tons x 17 rub./kg x 1000 x 30 days. | 1 020 000 |

| 2 | Wire | 800 kg x 6.5 rub./kg x 30 days. | 156 000 |

| 3 | Acceptance of tires | 3 t x 30 days. x 20% x 1,500 rub./t | 27 000 |

| Total | 1 203 000 | ||

With annual expenses (including initial investments) of 9,010,000 rubles. and an income of 14,436,000 rubles, a business with the given parameters will pay for itself in six months.

How much does it cost to start a tire recycling business?

The cost depends on several factors.

The price of equipment for processing tires into crumbs depends on its type, manufacturer, and technical characteristics. For example, tire recycling machines will cost:

- single-shaft - in the range of 120,000 - 2,800,000 rubles;

- twin-shaft – from 450 tr.

- grinding installation – from 770 t.r.

If we consider lines for grinding used tires into crumbs, which perform a range of work with a productivity of 500 kg/h, you need to calculate from 1.3 million rubles. Equipment for a mini-factory will cost from 10 million rubles.

These are far from the only business costs that an entrepreneur will have to bear. It is necessary to take into account the costs of premises, personnel, registration and other expenses.

Production facilities and warehouses

Tire recycling as a business will require premises. It is required for the following:

- placement of equipment;

- storage of raw materials;

- storage of finished products.

To install the line you will need from 200 m2. You can store old tires in an outdoor hangar or a fenced-in area for unloading recyclables. Acquiring the necessary premises can become a burden for a new entrepreneur.

An alternative is to rent the required space. The rental cost, depending on the region, can range from 20 to 100 rubles/month.

Personnel costs

Fixed expenses must be taken into account, including the wage fund.

It is calculated based on the number of employees, the size of their salaries and contributions to the budget.

For the uninterrupted operation of a production line with an output capacity of finished products (crumb rubber) of 150 tons/month, about 10 people are required. Approximate monthly wage fund – 500-550 tr. These are average calculations and may vary depending on the region of Russia.

Other expenses

The monthly expenses of this business are approximately 800 thousand rubles.

Rubber processing as a business is accompanied by other monthly costs:

- Purchase of packaging bags (containers) for finished products. The price of a 30 kg bag will be 8 rubles, based on monthly consumption it comes out to 4 thousand rubles;

- Communication – 10 tr;

- Unforeseen expenses - 10 tr;

- Average energy consumption data for the production line, calculated based on the production volume of finished products of 150 tons/month. equals approximately 100 rubles/month;

- Maintenance – 50 tr;

- A separate expense item is the replacement of cutting elements (knives) – 35 thousand rubles;

- Garbage truck services - 20 tr.

Adding up the cost of rent and salary, the amount of fixed monthly expenses will be about 820 rubles.

License to enter and sell

You can find information on many websites that a license is required to recycle tires as a company. Tires have the fourth hazard class. In accordance with the legislation of the Russian Federation, a permit is required for the collection and disposal of this type of waste.

Before submitting documents, an entrepreneur must have:

- production area;

- industrial with a sanitary zone;

- equipment;

- permits from Rosprirodnadzop, Rospotrebnadzor, fire inspection.

The cost of the license is 7.5 thousand rubles. Receipt time: 45 working days. When using the services of intermediaries, the cost of obtaining a permit increases several times.