People learned to produce glass products a long time ago, but glass has not lost its relevance in the modern world. Store shelves are lined with products in glass containers - mineral water, juices, canned food, baby food, coffee, etc. Glass container production volumes are growing every year. Is it profitable to create your own production of glass bottles, what is the technology for their production and is such an enterprise profitable - read about this in the article.

Recycling of raw materials is a poorly developed business due to the fact that entrepreneurs still poorly understand the essence of the technology. The problem is that in Russia there is no effective glass waste management system, and advanced management tools are not being implemented.

Business structure

This is the totality of the production parts of the enterprise that are included in it, as well as their interrelationship.

The structure of the glass bottle production business looks like this:

- main production (result of activity - finished products);

- auxiliary production (for example, equipment repair, energy supply);

- servicing production (provides main and auxiliary production with transport, warehouses, etc.).

It is through the effective interaction of all elements of the production structure that the highest results and profits can be achieved.

Form of entrepreneurship

Before starting the production process, it is necessary to legally formalize the future enterprise. You can register as an individual entrepreneur or open a legal entity.

For state registration of a legal entity, you need to complete the following steps:

- choose the name of your company, as well as its legal address;

- collect information from the passports of all persons who will be the founders of the company;

- form the authorized capital of the future organization (for an LLC this amount is 10,000 rubles);

- prepare the charter of the enterprise, approve it by the co-founders, prepare an order for the appointment of a director;

- select code 23.1 OKVED (production of glass and glass products);

- choose a tax system.

After this, you need to fill out an application form, pay the state fee (4,000 rubles for an LLC) and contact the tax office with a package of necessary documentation.

To register as an individual entrepreneur, it is enough to write a standard application, make a copy of your passport, and provide a receipt for payment of the state fee in the amount of 800 rubles.

Requirements for workshop premises

In order to install the necessary equipment, you will need a large room, and you also need space for a warehouse where finished products will be stored and packaged.

A building for a workshop for the production of glass bottles must meet certain requirements:

- should be located away from the residential area;

- mandatory presence of a water supply system;

- availability of sufficient energy capacity;

- convenient access road.

It is quite difficult to find space to launch production of the required size, especially in large cities. This is something that can cause certain difficulties in opening such a business.

Transport

Glass products are best transported in closed trucks so that the product is reliably protected from accidental damage. Before transportation, boxes with bottles must be secured in the body with straps.

In the early stages of a business, you can rent one or more trucks. This will allow for efficient delivery of raw materials and transportation of finished products. With the development of the volume of manufactured goods and the expansion of production, you can think about creating your own fleet of vehicles.

Staff

The success of any enterprise, and especially one that produces glass products, largely depends on the competence of its employees. Therefore, special attention should be paid to this stage.

At the initial stages of production development, specialists will be required:

- Technologist. Ensures the efficient operation of the production workshop and also controls product quality.

- Foreman. Monitors compliance with production safety rules and ensures the completion of shift tasks.

- Equipment and machine maintenance workers (2-3 people).

- Electromechanic. Ensures uninterrupted operation of electrical mechanisms.

If production volumes are large, then it is necessary to create a product sales section. You can also hire a specialist to resolve personnel issues or do it yourself.

With the expansion of production volumes, the staff must also be increased for the clear and smooth operation of the organization.

Ode to the Bottle: History and Production of Glass Vessels

Having read an extremely interesting publication about the history of glass, I immediately wanted to delve into such a specific topic as the history and production of glass objects. But not all at once, but those who are close to me, and about whom I know something from personal communication with them. I will continue from the moment when glassmaking began to grow from artisanal into mass industrial production and became an object of everyday life. This happened at the end of the 19th century. Guess what glass objects the Bottle Maniac might write about?

Ode to a Bottle

1. About vessels in general.

The Encyclopedia defines a bottle as “a container for liquids with a narrow neck.” According to historians and archaeologists, the first bottles began to be produced in the Middle East and North Africa in the 6th century. They had “ears” for straps for ease of carrying. Before this, liquids were stored and transported in earthenware (amphoras), copper jugs, wooden dishes and wineskins, which was not very convenient and practical. BOTTLES became almost the first objects of glass production .

The first experiments in the production of bottles were varied - the vessels turned out to be crooked, cloudy, of incomprehensible color and shape (I must say, even now they turn out like this from not very experienced glassblowers, centuries flash by - nothing changes), but they were already light and comfortable, which just what was needed for the production and storage of drinks (convenient - perhaps, but light - a controversial statement, especially when a small bottle weighing 4 kg comes from the workshop... uh... but oh well).

When glass craft developed in Venice and the fame of Venetian products went far beyond the borders of the Apennine Peninsula, local craftsmen cast bottles in metal molds and they became artistic products: bizarre in appearance, tall and graceful, flat or almost spherical, decorated with convex relief designs depicting not only flowers and fruits, but also genre scenes from mythology. In such bottles, drinks and seasonings were served on the table in rich houses (those were blessed times, eh!). Others were used for storing other liquid products, but they were also very expensive at that time.

In the 17th - 18th centuries, medicines and perfumes began to be stored in glass vessels. A bottle without a cork is no longer a bottle, but simply a vessel for liquid. At the same time, ground stoppers made of glass or cork oak bark appeared, providing an airtight seal; Before that, corks made of various materials were used (even a bunch of bast), and on top, as a rule, they were filled with wax, on which the owner or manufacturer of the product put his stamp. Sealing wax began to be used for these purposes much later.

Factory production of glass in Russia began in 1635. Around the same time, they started producing bottles. The first domestic bottle was produced at a glass factory built in the area of the current Istra station near Moscow, and was intended only for pharmaceutical purposes.

A little later, under Peter I, the “bottle” measure appeared.

Russian bottle = 1/20 of a bucket = 1/2 of a shtof = 5 glasses = 0.6 liters (the half-liter appeared later - in the twenties of the 20th century). Since the bucket held 20 bottles (2 0 x 0.6 = 12 liters), and in trade the count was on buckets, the box still holds 20 bottles.

Or like this:

After the creation of the metric system in 1792, the wine bottle began to serve as a measure. Moreover, its production was strictly controlled. The 0.75 liter capacity was approved in 1866. This was not chosen at random: a case of 6 bottles (4.5 liters) was equivalent to a gallon according to the British Imperial system. And the practical side: a 0.75 liter bottle can be poured into 6 wine glasses (or 6 wine glasses).

At the end of the 19th century, American engineer Michael Owens invented an automatic bottle production machine. By 1920, approximately 200 Owens machines were operating in the United States. Soon such machines became widespread throughout the world. Since then, bottles have been one of the most popular types of glass products. They are so different! In terms of purpose, shape, color, capacity - one thing remains the same - they are glass (I am not taking plastic containers into account here - these are also containers, of course, but we are talking about real bottles ).

In the USSR, the number of types of bottles produced for food liquids was quite limited, in accordance with the current standard, only a few dozen: for still wines, champagne, cognacs, vodka, liqueurs, juices, beer, soft drinks, vegetable oil and dairy products, in contrast to the perfumery, cosmetics and pharmaceutical industries, where there is a great variety of glass containers. But my excursion into history is again not devoted to all vessels in a row, but only to the most perfect ones - bottles for wines and other alcoholic products.

In Madrid there is the only museum in the world where more than 10 thousand examples of glass vessels from all over the world are exhibited (I want to live in this museum).

2. Biography of the bottle.

Once upon a time they drank wine instead of water (diluted, of course, to the color of amethyst). Until the beginning of the 17th century, wine was considered the one and only healing, strengthening, long-lasting drink. In cities, drinking raw water was dangerous. Ale without hops spoiled very quickly. In addition, in those days there were no drinks containing caffeine. To store wine, in addition to earthenware and wooden utensils, they also used large leather bags made from the whole skin of goats or sheep, specially tanned. They could hold up to 60 liters of fermented grape drink. For large wineskins with a capacity of 300 liters, the skins of oxen and buffaloes were used. The sewn skin was turned inside out - the wool and undercoat served as an additional filter for wine. The outside of the skin was rubbed with salt, and the inside was impregnated with tar. The taste of wine in such a vessel acquired a “smoky” hue. In the 17th century everything changed: chocolate went around the world from Central America, coffee from Arabia and, finally, tea from China.

At the same time, the art of distilling water was developing in Denmark, distillers for cheap white wine were being invented in the west of France, and hop additions turned ale into a much more “hardy” beer; In the largest cities, clean water began to flow through the pipes, which their residents previously lacked. The threat of extinction loomed over the wine industry - new ideas and fresh projects were needed.

Therefore, it is no coincidence that the creation of the most famous brands of wine, which are considered classic today, dates back to the second half of the 17th century. Their success was facilitated by the invention of glass bottles.

A bottle more similar to the modern one was first produced in 1630 by Englishman Kenelm Digby. However, it was more of a decanter than a bottle. A decanter is a special decanter into which those who like to do everything correctly pour wine before pouring it into glasses. Mr. Digby's work, made of thin and fragile glass, was intended to bring wine from a barrel in the cellar to the table. Round bottles made of thick glass, dark brown and green, began to appear. After all, as you know, wine does not like light and should be stored in maximum darkness.

It is noteworthy that in the matter of bottle production, Russia practically did not lag behind the West. The production of glass bottles began in our country just 5 years after Mr. Digby's invention. This is despite the fact that around the same time in Russia they generally learned what glass was and how to make it. Since then it has become a tradition - liquids (except oil) are better in glass.

3. My declaration of love to the Bottle.

Look at the bottle once in a lifetime, not as a shell of a drink, but as an independent work of art! Her form is perfect, like that of a woman, she is slender and graceful; she’s alive... She’s so pleasant to hold in your hands, she’s pliable and responsive (let’s leave Freud alone), she’s ready for anything, and it’s completely unfair to treat her like an ordinary meaningless object, or even like trash that you don’t feel sorry for throw away.

A few photos of old gutte bottles from my home collection:

4th dream of the Bottle Maniac: some hundred or two years will pass, and the bottle will become a very rare antique item, an expensive gift, worth only on the table of true connoisseurs of beauty. Now wines are poured into boxes and plastic bags, it’s becoming less and less common to see an elegant bottle or a solid damask on the table, even the dishes are being replaced by paper plates and plastic glasses - it’s so convenient - wow! and threw it away... where is the porcelain and earthenware, silverware, crystal glasses? There are no them, what was broken, what ended up in collections, what was lost when moving - life is fast and we have no time to think about beauty...

Fragile glass faces the same fate, it is heavier than cardboard, it is not so convenient to store, it is more difficult to recycle, I can name a bunch of other reasons why bottles will soon be replaced by more advanced materials. And people will forget about glass bottles, and only occasionally, on major holidays, such a rarity will appear on the table in the homes of wealthy people - a glass bottle of wine, whiskey, cognac... (I woke up - it was a good dream, I often dream about it)

They also say that it is in beautiful bottles that genies are most willing to settle, ready to fulfill any wish of the owner of the bottle, so be careful... I sincerely believe in what I write. And it’s not just me, Ray Bradbury has a wonderful story “The Blue Bottle” - it’s short and very philosophical, read it at your leisure, you won’t regret it.

I really love this object, its form, its soul; I hope I was able to convey in words what I feel when I pick up the BOTTLE.

Facts and some photographs were found on the Internet, some of the photographs and thoughts are my own. The article is not educational, the Internet is full of information about bottles with the most contradictory information, if you want - dig, read, share...

The author of the article about glass (link at the beginning) promised to write more about lampwork, and if you are interested, I can write about the hammering technique and blowing large formats - bottles, of course.

Thank you for your attention, your Bottle Maniac, Olga Rodionova

Where to look for raw materials

In modern society, consumers have a growing interest in various products sold in glass containers. Consequently, the volume of glass waste is also growing. However, in Russia there is practically no waste sorting system. There are only 60 large waste sorting complexes operating in the whole country. As a result, about 92.5% of glass containers in Russia are sent to landfill.

The collection of raw materials can be organized as follows:

- install stationary containers for glass collection;

- organize a mobile collection point for glass containers;

- conclude an agreement with manufacturers of glass products on the transfer of broken glass;

- collect raw materials at a solid waste landfill.

What is necessary

First of all, the business plan “Production of glass containers” emphasizes that a legally capable enterprise that has entered into an agreement for the supply of equipment for the production of glass containers must have its own premises.

Given the fairly large dimensions of the production line, it is necessary to coordinate the requirements for the premises with suppliers. In addition to sufficient area, it is necessary to connect all communication lines. Starting from the supply of electricity and water, ending with heating and sewerage.

By the time the installation of equipment is completed, the staff of workers who will service this equipment must be fully staffed. The supply and installation of equipment takes a long time, so there is no need to waste time on downtime associated with recruiting personnel.

Production

The process of producing glass bottles occurs in several successive stages:

- Raw materials are supplied to the receiving hoppers of the glass line.

- Raw materials are sent to consumable bins. There, the batch components are dosed using weighing dispensers in the required proportions, as well as the batch components are mixed in mixers.

- The charge is fed into the furnace compartment, then into the glass melting furnace.

- The glass melt is boiled and then prepared for formation in feeders.

- Products are given their final form in glass-forming machines.

- Heat treatment of products in annealing furnaces.

- Visual and technical quality control of the product, as well as testing for heat resistance and pressure.

- Packaging of finished products.

- Transportation of products to the warehouse or to the customer.

Types of glass

Glass is a material that is obtained by cooling a molten mass of quartz and soda. Glass products are transparent and colored.

In order for the finished bottle to be colored, different dyes are added to the glass (for example, a cobalt compound for blue, manganese for violet, etc.).

Equipment

The machines are highly expensive. You can order the entire production line from the manufacturer according to the parameters you need, or you can buy each machine separately.

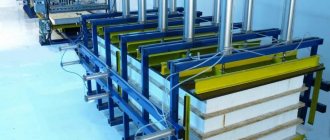

The production line includes the following types of equipment:

- glass supply line;

- glass raw material crusher;

- glass forming machine;

- glass melting furnace;

- cooler

It is better if production is automated as much as possible; this will reduce the risk of injury in the enterprise and also provide income tax benefits.

A variety of mold compositions are used in glass production. They are:

- drip and vacuum;

- pneumatic and mechanical;

- pressing, blow molding and blow molding;

- carousel, conveyor and sectional.

To register a business, you will need documents that confirm the quality of the equipment.

Technology

The technological process for the production of glass products in general looks like this:

- collection and preparation of raw materials;

- composition formation;

- cooking - the mixture is placed in the oven. Water and other chemicals should be boiled out of it (as a result, the composition becomes completely transparent);

- cooling - the molten mass is taken out of the furnace and allowed to cool;

- forming – bottles are formed using glass molds;

- firing of finished forms in a kiln;

- processing of finished products.

The entire production process of glass products must comply with technological standards.

Profitability

To start your own glass bottle production business, you need to invest a significant amount, but such a business will begin to make a profit in the second year of operation. In monetary terms it looks like this:

- expenses (equipment, rent for premises, raw materials, payment for energy resources, staff salaries, taxes) – 11,500,000 rubles;

- annual income from the sale of glass products is 12,200,000 rubles.

Variety of cans and bottles in our catalog

It is worth noting that we manufacture a wide variety of container options, including our online store that offers the purchase of glass bottles with a stopper for tinctures and canning jars. Their volume can be completely different: 35 ml, 50 ml, 100 ml. Even if your product requires the use of non-standard types of glass bottles, we will always meet the customer halfway and discuss all possible packaging options. In addition, you can additionally purchase lids for such containers, select a design from the presented sketches, and design jars and bottles as required by the corporate style of your company.

Sales markets for finished glass containers

The most significant consumers of glass containers on the Russian market are organizations producing alcoholic beverages and beer. Glass products can also be sold to canneries, beverage and juice manufacturers. Mutually beneficial agreements need to be concluded with such enterprises.

It is wise to research your and surrounding areas for the presence of distilleries and breweries. If there are such enterprises, then you can agree with them on the supply of bottles for specific drinks: champagne, wine, vodka, etc.

The production of glass bottles is a very expensive business. To achieve success, you need to invest all your effort, time and entrepreneurial savvy into it. If everything is done correctly, then this business will pay for itself in full. We recommend looking at existing glass manufacturers and conducting competitive intelligence.

30.01.2020