Glued laminated timber is one of the modern types of lumber. When building wooden houses, it acts as an alternative to rounded logs and profiled beams. Complex production technology leads to higher prices for the material, but in return buyers receive the highest quality and excellent performance characteristics of a log house.

What it is?

Glued laminated timber is a combined building material . Its basis is sawn boards, which are glued together using adhesives using special technology. For production, lamellas free of defects and knots are used.

Glued laminated timber is subjected to profiling - this allows you to create the desired cut geometry for quick and efficient construction of structures.

It is also devoid of the disadvantages inherent in natural wood - flammability, tendency to deformation and significant shrinkage. But thanks to the modern approach and the use of adhesive mixtures, the material acquires additional useful properties - high strength, thermal conductivity and dimensional stability .

A house made from this material is durable, warm, cozy, with the characteristic microclimate of natural wood. And it can be built in the shortest possible time.

Gluing machine

Gluing machines for wooden structures are equipped with either glue rollers or a pouring mechanism. Gluing machines significantly reduce the cost of equipment, but, as practice shows, they are unproductive in the production of timber, where high quality gluing is required.

In addition to the low drawing speed (about 20 m/min), such rollers are initially designed for PVA adhesives, which are not used for making timber. Some manufacturers solve the problem by regrinding the rollers, by applying small notches, but this modernization does not affect the broaching speed.

Therefore, for small volumes (up to 150 m3/month), it is more effective to use manual glue spreaders.

This device consists of a small container that holds 1.5-2 kg of glue, a handle, a dispenser and a glue roller. In 4 minutes, 2 operators can prepare lamellas for one load of a 6-meter press. In fact, it is 2 times faster than working with a glue roller machine. The main disadvantage (apart from the human factor) is that it is impossible to control the exact consumption of glue.

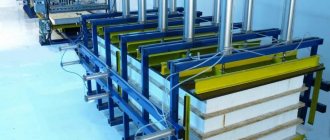

Therefore, the best option for a timber production enterprise is belt-type glue-applying installations with feeding and receiving roller conveyors.

Divided into two large groups:

Constant circulation machines

– when passing the lamellas, the glue is applied in a continuous curtain. The consumption is set in advance, the remains of unused glue and glue spilled past the board fall into the tank, from where it is sent back to work using a pump. The machine can be equipped with mixers (relevant when working with EPI), or apply glue and hardener separately (when using MF compounds). When operating mixers, periodic washing of the equipment is necessary, which results in losses of unused adhesive mass - about 1.5 kg. With the separate application technology, washing is not required and the loss of adhesive components is almost zero.

Mix application machines

– equipped with a static mixer, which looks like a spiral of a certain length and diameter with multidirectional turns. The ingredients of the adhesive mixture are pumped through this spiral under high pressure, which ensures their displacement, after which the adhesive mass enters the tube. The system operates on a “start/stop” principle - the supply of glue begins as soon as a lamella appears under the tube and stops after it has passed through, ensuring maximum material savings. Glue loss – 150-200g/shift.

All filling machines are equipped with accelerating blocks, which provide a drawing speed of 80-150 m/min, fast loading of the press and the same quality of gluing of lamellas in the package.

By the way, many glue manufacturers provide their glue-applying machines (for a nominal rental or free of charge) when using their products. But such conditions are offered only to large enterprises that can ensure consumption of adhesive compositions of at least 1.5 tons/month.

What is better - regular timber or laminated veneer lumber?

When choosing between traditional profiled timber and a glued variety of lumber, you should focus on the positive properties of the first.

The advantages of profiled timber include the fact that it is a solid solid wood . This is a completely natural building material that is highly environmentally friendly. It can be treated with solutions that prevent rotting and fire, but they do not emit harmful fumes or odors.

Glued cannot boast of absolute safety - its structure contains

synthetic glue , which can have a negative impact on health due to fumes.

Another advantage of profiled material is its low cost compared to the glued type. The latter will cost about 30% more.

In addition, in classic timber there is natural air exchange, creating a special microclimate in the home.

But profiled is inferior to glued in terms of variability in size, levels of humidity and shrinkage , the likelihood of deformation and partial loss of properties during operation. It often requires finishing work to improve aesthetics and periodic caulking of emerging cracks.

Main stages of production

The manufacturing process of building materials consists of several stages:

- Reception of raw materials - this stage involves a visual inspection of raw materials upon receipt at the warehouse.

- Wood sorting - during this procedure, low-quality lumber is removed, and the sorted logs are stacked.

- Drying of lumber is carried out in special chambers and takes about 7–8 days.

- Preliminary planing is a stage necessary to identify and eliminate defects in raw materials. For this, a four-sided machine is used.

- Trimming is a process aimed at eliminating defects; the final product is high quality lamellas.

- Splicing the resulting lamellas is a stage that includes processing the prepared materials with glue, as well as placing them in the storage section.

- Final gouging is the finishing of the material.

- Pressing is the process of placing planed lamellas into a pressing machine. There they remain for half an hour under high load.

- The final stages: quality control and packaging.

Quality control of finished laminated veneer lumber

The first three stages can be excluded from the main list. This is allowed when a specialist purchases raw materials that have already been prepared and dried.

Classification

Several types of material are used in construction, depending on the intended purpose and profile configuration.

Types of material by purpose :

- Window and door . It is made from at least 4 lamellas and is used in areas where window and door openings are installed.

- Wall. The number of lamellas reaches 2-3; it is used for the construction of walls in one-story houses and buildings with an attic.

- Support . The type with the greatest load-bearing capacity. It is used to construct building frames, floor beams and load-bearing supports.

The most popular parameters for wall beams for construction are 100-160*180 and 180-270*260 mm.

Wall timber can be made with or without a thermal insulation layer.

We recommend: How to build a sauna from profiled timber? DIY construction technology

Types by profile type :

- comb - equipped with fine teeth cut on the sides of the product;

- Finnish profile – forms a tongue-and-groove connection, its surface is almost flat;

- German profile - has from 4 to 8 connecting grooves, forms the strongest module.

Room

The plant should be located on the outskirts of the city, in a place with access roads for unloading raw materials and loading finished products. Minimum area – 400 sq. m.

Of these, 200 square meters are occupied by the production workshop, 100 square meters. m - warehouses for storing wood and finished products, 70 sq. m – room for drying wood, 30 sq. m - administrative premises and a bathroom.

To open your own production of laminated veneer lumber, you must meet many requirements:

- Constant air temperature in the room is about 18 degrees, humidity is no more than 65%;

- Fire-resistant materials are used for floors and walls: tiles, concrete, brick. A complete list of requirements for the level of fire safety in the workshop can be found in SNiP 21-01-97;

- Availability of heating, water supply, sewerage, ventilation system (requirements for it are described in SNiP 41-01-2003);

- Ceiling height – from three meters;

- Three-phase electrical network.

It is important to think in advance about how to dispose of wood waste . It is realistic to sell them as fuel raw materials or offer them to enterprises producing fiberboard and chipboard.

Workshop rent will be approximately $2000-2200 per month, repairs and finishing – about $6500.

House kits from the manufacturer

A timber house kit is a building kit consisting of several hundred elements intended for the construction of a building. In essence, these are ready-made houses in disassembled form.

Important! Installation of a house kit made of laminated veneer lumber is carried out only on an established foundation.

All parts of the kit have strictly verified dimensions, made in accordance with the architectural design. The elements are matched to each other, which greatly simplifies and speeds up construction.

The assembly includes:

- frame crown;

- interfloor ceilings;

- roof base;

- rafter system with lathing;

- pillars, logs, beams;

- external and internal walls;

- finishing and rough floors.

The kit includes assembly documentation with a detailed assembly diagram .

Each part must be numbered and packaged.

What's included in the complete package

A house kit is a kind of building kit. It consists of a complete set of elements necessary for the construction of an object. Upon agreement, preliminary antiseptic treatment of the timber is carried out. The house kit includes numbered wall parts, beams, rafters with sheathing and other materials. When transporting it, a strapping frame made of wooden boards is installed.

A ready-made house kit made from durable laminated timber simplifies construction, increases its efficiency and reduces cost. The Garden House company uses the highest quality laminated timber for the construction of houses. Maximum speed of construction and complete satisfaction with the result are also ensured by high precision of parts and professional assembly of the house.

Production of laminated veneer lumber

Production technologies were developed in Finland about 30 years ago.

Nowadays, modern laminated timber is mass-produced all over the world.

The resulting product is processed and completely ready for use.

Raw materials for production

Manufacturers prefer to use coniferous trees due to their availability and low cost. Pine, spruce and larch trunks are used cedar and fir wood is used abroad . Due to the high cost of raw materials, oak and ash timber can only be made to order.

In the production of multi-layer timber, natural materials are often combined. Spruce and pine are used for the outer layers - their wood structure is more uniform. Larch and cedar are used for internal inserts - they are characterized by high strength.

The most valued raw materials are from northern wood - it has the highest strength class.

Types of glue

Several types of glue are used to make laminated veneer lumber. They differ in classes of water resistance, operation and environmental safety.

- Melamine. Transparent adhesive used in Russian and European production for the construction of long-span structures.

- Resorcinol . A dark composition with increased moisture resistance; it is used to glue the outer parts of the timber for use in conditions of high humidity. This type of material is used by US manufacturers in shipbuilding, bridges and open structures.

- EPI system . Transparent adhesive composition, used in low-rise construction in Japan and Russia.

- Polyurethane . It has a transparent structure and hardens quickly. Suitable for gluing window and door beams.

We recommend: What and how to decorate the inside of timber houses - materials and technology. DIY interior decoration

Quality Standards

The production of laminated veneer lumber does not require a license. But products must meet quality standards confirmed by relevant certificates.

State standards for laminated timber:

- GOST 20850-84 “Glued wooden structures. General technical conditions”;

- GOST 16588-91 “Lumber products and wooden parts. Methods for determining humidity”;

- GOST 19414-90 “Massive laminated wood. General requirements";

- GOST 25884-83 “Glued wooden structures. Method for determining the strength of adhesive joints during layer-by-layer chipping”;

- GOST 15613.4-78 “Massive laminated wood. Methods for determining the tensile strength of toothed adhesive joints during static bending.”

Manufacturing technology

- Preparation of raw materials . Undried and uncut boards are sorted, sawed into blanks according to specified parameters, peeled of bark and sent to drying chambers. The final moisture content of the board should not exceed 8-12%.

- Defect removal and calibration . Each board is processed on four-sided machines. This allows you to eliminate wane residues, knots, cracks and other defects.

- Grinding . Finishing of the lamellas is carried out to ensure geometric accuracy and tight fit of the workpieces.

- Gluing . The glue application machine applies the glue to the surface of the wide side of the workpiece in an even layer. Then the lamellas are pressed into solid timber under a pressure of 15 kg/m2 for 30 minutes.

- Profiling . On the sides of the beam, cuts are made in the form of tenons, ridges, and grooves in accordance with the planned configuration.

- Treatment with protective compounds . Finished products are impregnated with mixtures that prevent burning and rotting of laminated veneer lumber.

Finished products are quality tested and packaged for shipment or storage.

Purchase of raw materials and consumables

Glued laminated timber is made from coniferous wood: pine, spruce, larch, cedar, oak and ash. It is economically profitable to use those varieties that are mined as close as possible to the plant.

Depending on the manufacturing technology of laminated veneer lumber, raw materials are purchased in the following types:

- sawlogs (the raw materials are debarked and cut into boards of the required parameters);

- unedged board (processing occurs with edge-edging equipment);

- edged board (such raw material is immediately sent for cutting).

Wood is the main raw material, but glue is also needed to make timber. There are several types of adhesive base, which is selected depending on the purpose of the finished product:

- polyurethane, which is universal and quick-hardening, after drying the seam turns out to be a light milky color;

- melamine-urea-formaldehyde - colorless and especially durable composition;

- universal transparent, are the most environmentally friendly. The timber, which is made using such glue, is widely used in low-rise construction;

- resorcinol, forms a dark seam after drying, used for products that will be used at high levels of humidity.

On the issue of raw material prices: the cost of wood varies, depending on the type and species. For example, the wholesale price for edged spruce boards starts from 6,800 rubles per 1 m3. And to produce 150 m3 of timber you will need about 400 m3 of wood raw materials and 550 kg of glue.

Why make it yourself?

If you have the necessary tools, you can make laminated veneer lumber yourself. This allows you to obtain material of non-standard dimensions that are not commercially available.

Doing it yourself will help you adjust the layers of timber according to strength, pliability, length, width, surface type . It can be used for finishing work, furniture restoration and other small jobs where purchasing large quantities of laminated veneer lumber is impractical.

note

For production, ordinary boards or slats from a construction supermarket are suitable.

For more thorough and precise processing, milling machines and grinders , but at home you can get by with a wood hacksaw and a plane . The surfaces to be glued are treated especially carefully - they are sanded, dust removed and degreased.

Gluing is carried out using ready-made glue, which can be purchased at retail outlets. It is necessary to strictly follow the instructions for applying and drying the glue.

We recommend: Building a private house from timber - stages of construction from foundation to roof

Clamps are used to secure and compress glued parts . After drying, the finished timber is finally planed and sanded.

Necessary equipment and its features

To produce structural timber you need to purchase special equipment.

The drying chamber is equipment that allows you to increase the production speed of profiled timber by 3 times. They are vacuum, convective, aerodynamic. The cost is about 1.5 million rubles.

Operating diagram of a drying chamber for laminated timber

Four-sided milling machine - designed for processing and sanding boards. The unit serves for uniform sawing of lamellas and ensures smoothness. The cost of the machine is 400 thousand rubles.

The fundamental distinctive feature of the line is the basing of the processed timber along the entire length and processing of the bases during the first pass

A double-sided tenoning machine cuts mini-tenons on both sides of the workpiece for gluing under a press. Applies glue under pressure to mini-spikes. The price ranges from 200 to 650 thousand rubles.

One kind of double sided tenoning machine, K4S6

The end splicing line is installed on a press; its length is 3, 4.5 and 6 m. This length does not always allow for gluing sections of lamellas of different lengths. As an alternative, a continuous splice line is used, the parts apply pressure to a specific section of the boards or a single joint.

Semi-automatic end splicing line FJS-20AH

An effective option is an automatic line that performs several functions at once: cutting mini-tenons, applying adhesive, splicing and cutting lamellas. Cost – from 1.4 to 2 million rubles.

Automatic line for the production of structural timber

What is Finnish laminated timber?

Finnish profile types include sections with complex configurations and insulation . The lower edge of such a beam is equipped with connecting tenons, and on the upper edge there are grooves corresponding to the size of the tenons. The stepped groove located between the spikes is deeper in the middle and shallower at the edges.

A sealing material is placed along the edges of the groove , and a heat-insulating synthetic tape . The groove is covered from the sides by the beveled edges of the upper beam. This design allows you to achieve a high level of thermal insulation, avoid moisture ingress and blowing through the structure.

This type of insulation is labor-intensive and expensive. Simplified and budget options involve compaction only in the center or only on the sides. This also allows you to achieve good windproof performance.

Advantages and disadvantages of the material

The demand for laminated veneer lumber is growing every day. This is due to the numerous positive properties and advantages of the material:

- Minimum percentage of shrinkage, which allows you not to wait for the house to shrink, but to immediately put it into operation.

- Excellent thermal insulation properties, often not inferior to brick.

- Does not require finishing - the surface of the timber is even and smooth, without cracks or defects.

- The timber is not subject to burning, rotting, wormholes and fungal infections.

- Maintains geometric proportions, does not deform or change shape.

- Glued laminated timber is easy to install, which significantly reduces the construction process.

- Provided proper installation, high moisture resistance and resistance to wind penetration are ensured.

- There are no restrictions on length, and the thickness of the product can include up to ten lamellas.

- The low weight of the products does not require the use of special construction equipment.

Disadvantages of laminated veneer lumber:

- The high cost of lumber compared to rounded logs and profiled beams.

- The need to maintain a certain level of humidity in the home in the absence of temperature changes.

- Low air permeability of structures.

- The need for additional thermal insulation during the construction process.

Some manufacturers use low-quality synthetic compounds for gluing, which significantly reduces the environmental friendliness of timber products.

Estimated business plan for a plant for the production of laminated veneer lumber

Organizational form and legal aspects of opening a wood processing plant

To register production activities, it was decided to open an LLC on the general taxation system.

OKVED:

- 20.20.22 Production of modified wood

- 20.30.1 Production of wooden building structures and joinery

Sales routes for laminated veneer lumber

- Organizations specializing in the construction of low-rise buildings.

- Trading enterprises engaged in the sale of building materials wholesale and retail.

- Individuals (population) constructing residential buildings, cottages, dachas and MAF (baths, gazebos, etc.).

Capital Investment

To carry out production activities, the following equipment was purchased:

- drying chamber – 510,000 rubles;

- edge trimming machine – 200,000 rubles;

- multi-saw machine – 900,000 rubles;

- four-sided machine – 1,110,000 rubles;

- automatic line for splicing lamellas along the length – RUB 2,150,000;

- tenon cutting machine – RUB 1,700,000;

- glue application machine – RUB 220,000;

- vertical hydraulic press – RUB 1,900,000;

- forklift – RUB 500,000

- beam crane – RUB 300,000

- sharpening equipment – 120,000 rubles.

Total: RUB 9,610,000

Production start-up costs

According to preliminary calculations, it will take 3 months to organize the technological process, during which the legal registration of the business, preparation of the production premises, assembly, installation of equipment and personnel training, commissioning, development of the technological process, and product certification are carried out.

Estimated costs for this period:

- Salary of personnel involved in organizing the production process, including taxes – 1,100,000 rubles;

- Rent of industrial premises (2000 m2 * 60 rubles * 3 months) – 360,000 rubles;

- Other production costs (vehicles, office equipment, travel expenses) – 150,000 rubles;

- Creation of warehouse stocks of raw materials (3200 m3 * 1200 rubles) – 3,840,000 rubles.

Total: RUB 5,450,000

Standard of material costs

The weighted average consumption coefficient of coniferous sawlogs for the production of timber is 2.925 m3/1m3.

That is, to produce 300 m3 of timber you will need 877.50 m3 of raw materials.

The consumption of the adhesive mass can be calculated using the formula: ((KL - 1) * chShZ * chDz * X * Keys) + (A * KSh * chTZ * KL * Keys * B * chDz * Y), where

CL – number of lamellas;

chShZ – rough width of the workpiece;

chDZ – rough length of the workpiece; X – glue consumption rate in kg/m2 when gluing onto a smooth fugue;

Keys – number of products per 1 m3 of timber; KSh – number of tenons per 1 glue seam;

chTZ – rough thickness of the workpiece; Y – rate of glue consumption for gluing onto a mini-tenon.

For this calculation, it is necessary to know the number of seams when splicing onto a mini-tenon (B) per 1 linear meter of lamella and the length of the cross-section of the mini-tenon (A). On average, 1 m3 of timber requires 4-6 liters of glue.

Estimated output and profit

From the 4th month, the plant’s operation is brought to its design capacity, producing 300 m3/month of construction timber. Sales price of 1 m3 of laminated veneer lumber – 11,200 rubles

Planned profit 300 m3 * 11,200 rubles = 3,360,000 rubles/month.

The cost of manufacturing laminated veneer lumber, taking into account monthly expenses from the 4th month of plant operation:

- rent of a production workshop – 120,000 rubles;

- salary of management personnel and workers (22 people in total) including taxes - 381,000 rubles;

- electricity, gas – 70,000 rubles;

- transportation costs – 40,000 rubles;

- material costs (saw logs, glue, impregnation) – 1,240,480 rubles;

- other expenses (travel expenses, services of third parties, depreciation) – 80,000 rubles.

Total: 1,931,480 rubles/month.

The cost of 1 m3 of laminated veneer lumber is RUB 1,931,480 / 300 m3 = RUB 6,438.27.

Useful videos

Characteristics and features of the material, advice and recommendations from a specialist, see:

Watch all the stages of laminated veneer lumber production - from sawing timber and drying blanks to cutting corner joints and coating with protective compounds: In the video below - the advantages and disadvantages of houses made of laminated veneer lumber, assembly features: The significant advantages of laminated veneer lumber make it

a popular and effective building material for the construction of durable buildings. The high price is paid off by the beautiful appearance of the building on the outside, and the comfortable and cozy atmosphere inside.

Adhesive system

The strength and environmental friendliness of laminated wood structures (GWS) largely depends on the composition of the adhesive systems used. The latter must ensure long-term strength, indestructibility and reliability of wall enclosing and load-bearing structures. The environmental friendliness of the finished material is also of great importance.

Types of glue for the production of modern KDK

The choice of gluing materials depends on the purpose and type of finished wooden structure:

| Type of CDC | Adhesive system | Peculiarities |

| Serial products and large wooden structures, parts of prefabricated houses | Resorcinol (based on phenol or resorcinol-formaldehyde resin) | Forms a durable, chemical-resistant black seam. In liquid form, it contains toxic components that are particularly hazardous to health. |

| Glued laminated wood of various types and classes of responsibility | Melamine (based on melamine-urea or melamine-formaldehyde resin) | Forms a strong white glassy seam. Contains harmful ingredients |

| Glued laminated timber used for construction projects | Polyurethane (PUR) | Ensures reliability, high functionality and environmental friendliness of ready-made DCs |

The Garden House company builds houses from high-quality laminated veneer lumber, the production of which uses health-safe polyurethane adhesive Purbond (Switzerland), HB S line.

Advantages of Purbond PUR adhesive systems

Purbond introduced its first line of adhesives more than two decades ago. This manufacturer was the first developer of PUR technologies used in the manufacture of load-bearing laminated wood structures. Today, Purbond one-component adhesive systems are widely used throughout the world. Their demand is explained by five main advantages:

- High viscosity. This figure is 24,000 Brookfield units, which is approximately 4-6 times higher than other PUR adhesives and melamine systems. Increased viscosity eliminates “hungry” gluing during the pressing process, during which glue particles penetrate into the pores of the wood. The seam is uniform, hard, and elastic.

- No additional components. The one-component nature of the material eliminates the dependence of the hardening rate on the ratio of the adhesive mass and the hardener. This ensures reliable adhesion of wood surfaces, the moisture content of which is up to 18%, and the amount of defects is reduced to a minimum.

- Improving working conditions for cutting tools. When planing in the area of adhesive joints, the blades become dull more slowly. Therefore, the periods between sharpenings are doubled.

- Environmental friendliness. In the production of PUR adhesives, formaldehydes and solvents that are harmful to health are not used. When solidified, only carbon dioxide is released into the atmosphere; in the cured state, the material is inert. Such products have environmental properties comparable to solid wood.

- Resource saving. For gluing, a minimal amount of substance is used, compared to other adhesive systems.

The Garden House company uses Purbond PUR adhesives for joining lamellas along the length (HB S049) and for the production of multi-layer timber (HB S209). The use of these materials eliminates delamination and destruction of the CDK.

Several projects of our houses made of laminated veneer lumber

Kontu-260

RUB 7,576,800

Maus-112

RUB 3,340,814

Kontu-218

RUB 5,950,560

View all projects