Business Features

The business of producing frameless furniture can rightfully be considered one of the most creative.

It is in this direction that an entrepreneur can realize all his design ideas, because the final product must be unique, individual, but at the same time organically fit into the interior of the premises. Frameless furniture primarily includes a “bean bag” - the so-called Bean-Bag. Externally, it is a bag that is sewn from durable and dense furniture fabric and contains some kind of filler (it can be either bulk material or soft synthetics). This type of interior item is becoming increasingly popular, although it came to us not so long ago. The reason is simple - such a chair, like any chair or an ordinary classic chair, fully performs its main functions, but at the same time takes up relatively little space and can be moved without much effort to change the situation or even put away in a closet. Accordingly, larger models can easily replace a sofa or even a bed.

The main target audience includes absolutely the entire population. However, if you look a little further, such pieces of furniture are most often bought by young people with average incomes, small apartments and those who follow modern trends. But the likelihood of selling such a chair to a conservative or wealthy person is extremely low - they prefer classic, traditional furniture. Hence, along with the universal model range that the workshop will produce, an excellent option would be to manufacture frameless furniture to order according to a rough sketch or at least the client’s sketches.

It is impossible to say unequivocally about the difficulty of entering the market. Of course, there is high competition in this not new business segment, but a customer-oriented approach, high-quality production, the use of safe materials and a unique design will easily allow you to find your client.

Features of the frameless furniture manufacturing business

The first frameless furniture was made in Europe in the 60s of the 20th century. In Russia, its production is only gaining momentum, so there is a chance to occupy its niche in this direction. The production of soft ottomans, armchairs and sofas is suitable for those who want to realize their design talent.

Frameless furniture differs from ordinary furniture in the absence of a rigid wooden frame. It is made from fabric, fur, leather and filler, which is most often polystyrene foam. Such products are convenient, take up less space than traditional ones, and are easy to move if necessary.

Tailoring of frameless furniture can be carried out to order according to the client’s sketches. You can start your own business producing bean bags even with a small amount of investment, doing sewing at home. Sales in this case are carried out through an online store or social networks. In the future, when there are more clients, you will have to think about renting premises and hiring staff.

Reference. Entry into the frameless furniture production business varies greatly - from 30,000 to 20,000,000 rubles. The amount of investment in the project depends on the financial capabilities and ambitions of the entrepreneur. To take a worthy place in the all-Russian market, you will need an amount of 3 million rubles.

Manufacturing technology

Frameless furniture, in particular a bean bag chair, is made extremely simply - it is sewn. To do this, fabric is purchased according to need, which will serve as upholstery. It should be resistant to abrasion and tearing, but at the same time be pleasant to the touch. When starting a business, you can choose a budget price segment, and later, when working with some clients, it is possible to manufacture furniture from expensive materials.

Next, using pre-made patterns, the fabric is cut into components for the cover. After this, the cover itself is sewn. Here it is necessary to pay great attention to the quality of the seams: they must be very strong, withstand significant loads, but at the same time not stand out from the general background of the furniture. The best option would be to use a double seam using unbreakable threads. In this case, it is necessary to determine the area where the zipper will be located, allowing you to remove the filler and, if necessary, wash the cover. Lightning should also not interfere with the user, be invisible and not cause inconvenience.

In the upper part of the case it is necessary to make a hole through which air will be released, and also to place a special handle for carrying.

After this, the purchased filler is placed in the case (placed in a special package, which must also be durable and not tear during its removal). The result is a finished bean bag chair that does not deform during use, is resistant to abrasion, and is also lightweight.

Production process

Let's look at the process of producing frameless furniture using the example of sewing a bean bag chair. It consists of two covers of the same size - internal and external, and a filler, which gives the product its shape.

To make one chair, about 5–6 m of fabric and 4–5 kg of polystyrene foam are consumed. The first stage of work is creating a pattern on paper. Then it is transferred to fabric, the parts are cut out and sewn together. A hole is left in each bag into which a zipper is sewn. On the inner case its length is 30–40 cm. On the outer case it is 1 m.

The lower part of the product is usually sewn from the remaining fragments of fabric to reduce costs. Next, the inner case is filled with polystyrene foam granules, zipped up and placed in the outer bag. To make the outer cover, dense wear-resistant fabric is used - velor, leather, jacquard. To ensure that the chair retains its shape and the fabric does not move, it is recommended to connect the bags together with Velcro in several places.

Attention! In 1 day, an experienced seamstress can produce 2 units of frameless furniture.

DIY bean bag chair. Stages of work

Cut the material according to the following pattern, adding 1.5 centimeters on each side to the indicated dimensions for seam allowances. It is better to cut out the side parts according to a pattern previously drawn on paper, then the parts will be symmetrical.

Pin the back and bottom part facing inward and stitch to the place where the zipper will be located, i.e. leave 30 cm of seam unstitched. Baste with a temporary hand stitch, straighten the seam allowances, baste and sew on the zipper. Open the temporary seams.

Pin facing inwards and stitch the front part and back parts. Pin and baste them with the bottom and back pieces.

All seams can be processed with an overlocker or a seam - an imitation of an overlocker, which is found on modern machines. Or, to reinforce the seams, you can fold the seam allowance in half and stitch over it.

Baste and stitch the front part. This seam should not be reinforced additionally. Turn the product inside out. Place a stitch along the perimeter of the front part, securing it with a fold 0.7 cm high. The resulting edging will strengthen the seam and give visual rigidity to the product.

Fill the case with foam balls. To do this, you need to take a 1.5 liter plastic bottle, cut off the neck and bottom so that you get a pipe. If the bottle has a waist, even better. Open the bag with the filler, insert the bottle into it and secure the bag with tape. Make sure that the neck of the bag is completely secured with tape and the balls will only spill out through the bottle. Unzip the chair and put the cover on the bottle. Close the zipper, fixing it at the “waist” of the bottle. Hold this area with your hand and turn the bag of filler over. Fill the chair to about 2/3 of its volume. If there is too much filling, the chair will not “hugg” and will be uncomfortable. If it's too small, it will sit too low.

All materials for the chair can be purchased at regular sewing stores. The only difficulty may arise with the purchase of filler. It is sold by companies engaged in the production of frameless furniture or manufacturers of thermal insulation materials. An important point is the quality of the filler. Ideally, polystyrene foam granules should be the same size - 4 - 5 mm. If the balls are too small, the chair will be heavy. If they are too large or of different sizes, then the fluidity of the filler will be lost, and you will have to distribute it inside the chair by hand. Also, sometimes the so-called “crushed material” is used to stuff frameless bean bags. This is recyclable material, which is made from defective foam boards. This kind of filler does not flow at all, but only squats under the weight of the person sitting and makes an unpleasant squeaking sound. If the filler has a strong chemical smell, it should be ventilated for several days in the open air, for example, leaving a bag of balls open on the balcony, or even pouring them into a fabric bag.

Where to start opening a business

Due to the fact that this category of product appeared on our market relatively not very long ago, it is necessary to carefully approach the process of starting to sell frameless furniture. At the first stage, it is necessary to find out who in the future will be potential clients who will be able to make similar purchases. Due to this, you will have to focus on a product that is in great demand.

After this, you need to select the premises in which you plan to carry out your trading activities. Then, without fail, you must take care of the range of goods that you will sell. It is desirable that it be broad and very diverse. And be sure to take care of advertising your own company at the last stage after completing the documents.

Business concept

Today, the production of frameless furniture involves the production of sofas, chairs, poufs, pillows, hammocks, and children's items. Products of different sizes and colors will complement any interior in an original and harmonious way.

To become a successful businessman, you will have to work hard and actively, constantly look for fashionable new items, and understand the texture of materials.

The main goal of the business is to constantly expand the range and improve the quality of manufactured goods.

What will be required for implementation?

To competently organize the idea under consideration for the production of frameless furniture, you need to draw up an effective business plan, which will reflect the following points:

- analysis of demand and activities of competitors;

- range of products;

- procedure for registering an enterprise;

- the amount of necessary equipment and raw materials for work;

- expenses associated with renting premises, salaries of staff;

- methods of selling goods;

- preliminary calculations of net profit, payback periods for investments.

Expenses:

- Registration of a business entity.

- Renting premises.

- Communal payments.

- Cost of equipment.

- Cost of fabrics.

- Filler cost.

- Cost of accessories (zippers).

- Cost of reinforced threads (MARS; ARES; Polyart; Neva)

- Seamstresses' salaries.

- Taxes and other obligatory payments.

- Advertising.

- Office expenses.

- Website creation (design, domain, hosting).

- Website promotion.

- Unexpected expenses.

Step-by-step plan for starting a frameless furniture production business

To organize a business producing frameless furniture, you need to rent a room to place a workshop in it. For a beginning entrepreneur, you can rent a small heated room with an area of 25-30 sq.m., which can accommodate 4-5 sewing machines for sewing covers. It is necessary to purchase sewing machines and provide good lighting in the room. You will also need a small warehouse to store raw materials and finished products. Since the products and raw materials - polystyrene foam - are bulky, it is advisable to allocate about 50-80 sq.m. for a warehouse at first. This room must be dry and clean.

Which OKVED code to indicate when registering a business?

If you are planning to open a business selling frameless furniture, then in this case you need to use OKVED code 46.47 - trading in household and office furniture. In the event that at some point in the future you plan to make similar furniture yourself, you can additionally indicate OKVED code 31.01 - furniture manufacturing.

What documents are needed to open?

Before starting work, you need to register an individual entrepreneur with a simplified form of taxation. What is the OKVED code for production

frameless chairs, sofas, ottomans - 36.1, 36.09 (wholesale trade of furniture).

When purchasing materials for production, it is necessary to require certificates of conformity and hygienic certificates for fabrics, polystyrene foam, and zippers from manufacturers.

It is also necessary to certify finished products so that they can be sold to consumers. This type of production is not subject to licensing.

What permits are needed for the production of frameless furniture?

To open an enterprise that will produce frameless furniture, you do not need any special permits or licenses. In addition to documents related to company registration and certificates confirming the quality of your products, it is also necessary to prepare project documentation. These papers must be agreed upon with representatives of the following institutions:

- MUP "Gosenergo";

- Rospotrebnadzor;

- Rospozharnadzor.

These approvals are mandatory for enterprises engaged in serial production of furniture. If you plan to work only on individual orders, you will not have to waste time and energy on resolving this issue.

Necessary equipment for the workshop

To produce frameless furniture, you need to purchase equipment:

- industrial sewing machines, 4-5 pcs. – 100,000 rubles;

- overlock – 20,000 rubles;

- table for cutting covers, 2 pcs. – 20,000 rub.;

- electric knife for cutting parts, 2 pcs. – 10,000-12,000 rubles;

- vacuum cleaner for filling cases with polystyrene foam – 700-1000 rubles.

In total, you need to spend 150,700 rubles on equipment.

Materials for sewing frameless furniture

In addition to the equipment, you need to buy the materials necessary for sewing:

- threads;

- zippers;

- furniture fabrics, leather for internal and external covers;

- granulated polystyrene foam and other consumables.

Costs for materials can be about 100,000-150,000 rubles.

How to choose equipment for such a business

If you are faced with the need to purchase various equipment and all kinds of materials, then when choosing them, you must pay attention to quality.

It is this criterion that most often determines the final cost of a certain type of furniture. Despite the fact that lower-quality materials are cheaper, you should not save on future clients, since negative assessments of your company are not at all necessary.

Frameless furniture manufacturing technology

If, in addition to selling, you decide to make frameless furniture, you must strictly follow the plan. First, you must find out all the preferences from the customer. After this, you can create a project of the proposed furniture and present it to the customer for inspection. As soon as the project is approved, you can safely begin manufacturing frameless furniture.

Making a bean bag chair

Making frameless furniture with your own hands should start with simple products, for example, sewing a beanbag chair. This piece of furniture will easily fit into any interior of the room. At the same time, even novice handmade fans are quite capable of sewing such a chair.

Bean bag chair pattern

First, you will need to take the finished patterns and transfer them to the fabric using chalk, and in this case, you will definitely need to leave seam allowances of about 1-1.5 cm. In this way, you will need to prepare a blank for 2 bags: an outer and an inner one. In any case, it is necessary to calculate in advance the dimensions of such furniture so that there is enough material for it, and also so that it “fits” into the dimensions of the room.

After the patterns are ready, begin the process of sewing the parts together. To do this, sew the wedges along the side edges, and then sew the top and bottom. At the same time you will need to sew in a zipper.

This way you will complete a small bag. The large outer bag is also made in a similar way, with a large zipper sewn into it at the last edge. If any decorative elements will be used, such as pockets or loops, these should also be sewn on at this stage.

It is convenient to fill the chair bag so that the filler does not spill out, using a paper funnel, which can be attached to tape

After the bags are ready, you will need to insert the outer bag into the inner one and start filling it with granules. To do this, you can use either a funnel or a regular plastic bottle. To do this, cut off the bottom and neck so that only one pipe remains.

The filling density of the bag chair is approximately 50 - 70 percent of the volume of the cover

This pipe will need to be inserted into a bag of polystyrene foam granules and secured well with tape. After this, the zippers on the bags are unzipped. The bags are put on an improvised pipe and secured with locks.

Next, carefully turn the container with the granules over and wait until they begin to pour into the inner bag. It needs to be filled to approximately 50-70% of the internal volume. If you want to adjust the rigidity of such furniture, then add more filler - it will become stiffer.

Note! If you are going to make your chair from thick fabric, you will also need to sew special valves into it so that excess air can be released. In this case, it will quickly adapt to the shape of your body in a timely manner. In addition, additional ventilation will not allow excess moisture to accumulate in it.

Financial calculations

Start-up capital

The initial investment amount will be approximately 715,000 rubles.

The main costs are presented in the table.

| Flow type | Amount, rub |

| Paperwork | 50 000 |

| Rent of a sewing workshop and office (100 m²) | 90 000 |

| Repair | 30 000 |

| Purchase of materials and accessories | 130 000 |

| Equipment | 205 000 |

| Office equipment and office furniture | 100 000 |

| 80 000 | |

| other expenses | 30 000 |

| Total | 715 000 |

How much can you earn?

The cost of manufacturing a regular bean bag chair will be approximately 1,000 rubles, but the selling price of the product increases at least 4 times, i.e. from 4,000 rubles. In one working day, a staff of five seamstress-cutters will be able to produce approximately 7 chairs. If 100% of the goods are sold, then the company will be able to earn 28,000 rubles every day. For 22 working days of the month, the income will be approximately 616,000 rubles. Taking into account current monthly expenses, net profit will be equal to 206,000 rubles/month.

Personnel formation

The administrative part of the staff consists of a director and an accountant. Working hours: Monday to Friday, Saturday and Sunday are days off. The positions can be combined; at first, they are performed by the individual entrepreneur himself.

Company administration salary and bonus:

| Job title | Salary, Rub. | Prize | Salary and bonus | FZP | ||

| % | rub. | months | year | |||

| Production Manager | 40 000 | 10 | 4 000 | 44 000 | 44 000 | 528 000 |

| Accountant | 25 000 | 10 | 2 500 | 27 500 | 27 500 | 330 000 |

The working category includes craftsmen, designer, and customer service manager. Craftsmen work in the production of frameless furniture in two shift teams of three people. Managers accept incoming orders and contact customers. The designer has an artistic education and works on developing models.

Salary and bonus of working and support staff:

| Job title | Staff units | Salary, rub. | Prize, rub. | Total bonus and salary, rub. | Full salary, rub. | Total, rub. per month for the total number of employees | ||

| % | rub. | months | year | |||||

| Master | 6 | 15 000 | 10 | 1 500 | 16 500 | 16 500 | 198 000 | 99 000 |

| Manager | 2 | 14 000 | 10 | 1 400 | 15 400 | 15 400 | 184 800 | 30 800 |

| Designer | 1 | 15 000 | 10 | 1 500 | 16 500 | 16 500 | 198 000 | 16 500 |

| Cleaning woman | 8 200 | 0 | 0 | – | 8 200 | 98 400 | 8 200 | |

Summary statement of the number of workers:

| Categories of workers | Number | Full salary month | FZP year |

| Basic | 9 | 146 300 | 1 755 600 |

| AUP | 2 | 71 500 | 858 000 |

| Auxiliary | 1 | 8 200 | 98 400 |

| Total | 11 | 209 500 | 2 514 000 |

| Contributions to various funds per month, rub. | 74 000 |

Total amount needed per month for salaries of all personnel and contributions to various funds: 283,500 rubles. We add this amount to the initial capital, since the company does not bring in enough profit in the first month.

Step-by-step launch instructions

- Registration . First, the company is registered as an individual entrepreneur operating under a simplified taxation system. Before concluding contracts with suppliers for raw materials and equipment, you must request from them certificates accompanying each type of material. It is also necessary to undergo mandatory certification in order to be able to sell the product to consumers. This type of activity is not subject to licensing. Next, it is necessary to prepare project documentation, which is submitted to the MUP Gosenergo, Rospotrebnadzor and Rospozhnadzor. All these documents must be completed by an entrepreneur who plans to establish serial production of furniture. To sew products for individual orders, this issue will not need to be resolved. The cost of processing all documents will be approximately 50,000 rubles.

- Premises . Calculate the area of the future sewing workshop based on the scale of production. For example, you plan to place 5 seamstresses in a room. For each you need to prepare a workplace. This is approximately 30-35 m². Tables for cutting material will also require additional space. Therefore, we add at least another 30 m². You should also equip a dry warehouse for storing finished products (20-25 m²). Thus, the total area of the rented workshop must be at least 80-90 m². If you want to make an office, you can allocate a separate room for it or rent space in another location. As for repair requirements, there are basically none. The only point that needs to be provided is high-quality lighting and fire alarm equipment in the production workshop. Rent will be approximately 70,000 rubles/month, and preparing the premises will cost you 25,000-30,000 rubles.

- Equipment and materials. To operate an office, you need to purchase a computer, office equipment, and furniture worth approximately 100,000 rubles. Finished goods must be stored on special racks. The cost of one item reaches 10,000 rubles. For a warehouse with an area of 30 m² you will need to buy at least three racks (30,000 rubles). Equipment that will be required to implement the business: industrial sewing machines (5 pcs.) – 110,000; overlockers (2 pcs.) – 40,000; cutting tables (3 pcs.) – 25,000; special installation press for fittings (1 pc.) – 15,000; additional available tools - 15,000. Raw materials for starting production will cost 130,000 rubles. These include: fabrics, fillers, accessories, threads.

- Staff . For a small factory for the production of frameless furniture, the following employees will be required: seamstresses - 5, equipment adjuster - 1, sales manager - 1, accountant - 1.

- Advertising and searching for potential clients. To ensure the protection of manufactured furniture from counterfeits, you should take care of its logo in advance and register it. This will not only be required for security, but will also form the basis of a successful advertising campaign. As for PR, at the initial stage of organizing a business you will have to spend about 80,000 rubles on it. The main sources of attracting potential clients can be the Internet, colorful leaflets, and newspaper articles.

Market analysis

Developing a strategy for any business project includes drawing up a portrait of the target audience. It is important to clearly understand who the product is aimed at. The future entrepreneur must analyze the market situation and assess the level of competition in his niche.

The target audience

Buyers of frameless furniture are young people with average incomes. Usually these are owners of small apartments, guys and girls who are interested in modern trends. Also, the target audience of the business includes young couples with small children; for them it is important that the child does not get hurt on the sharp corners of the furniture during active games.

People of advanced age with above-average incomes hold conservative views. They are unlikely to buy bean bags, as they prefer traditional furniture made in a classic style.

Bean bags are purchased in bulk for:

- holiday homes;

- hotels;

- nightclubs;

- cafe;

- children's institutions.

A business plan for the production of frameless furniture should cover the main audience of buyers. Who buys frameless furniture? As a rule, these are modern young people who strive for everything new and unusual. This type of furniture is also chosen by parents who want to protect their child from sharp corners. Or older people who value comfort.

The bean bag chair is in greatest demand - comfortable furniture that takes the shape of the person sitting on it. These chairs are very light and compact, even a child can move them around the apartment. They are purchased for cottages, clubs, cafes, kindergartens and so on.

When manufacturing frameless furniture, it is very important to use the principle of exclusivity, that is, the models should be varied in design. Achieving this is not at all difficult, given the wide range of furniture fabrics presented on the modern market. Look for new original styles, experiment with color and texture, produce custom-made furniture and you will expand the market for your products.

You can produce custom-made furniture for organizations and institutions with their logos and symbols, sew replaceable covers, make ottomans and armchairs according to customer sketches.

Make armchairs for children from bright fabrics, with pockets, lacing, appliqués or any other interesting elements.

Assessing the level of competition and risks

It is better to start the production of frameless furniture in a city with a population of more than 100,000. For the successful development of a business project, it is necessary to collect information about existing competitors. If they exist, you should familiarize yourself with their range and pricing policy, and study reviews of their work. This information will help the entrepreneur avoid mistakes made by existing companies in the city that manufacture frameless furniture.

The main business risk is a small flow of customers . To achieve success, you will have to work hard, constantly improving product quality. To find your first buyers, you need to make yourself known by creating groups on social networks, advertising your product on city portals and forums.

Furniture is not for everyone

Before moving directly to the discussion of the process of organizing the production of frameless furniture, let's see who are the people who buy bean bags and other similar furniture?

Active young people, not conservative in their views, who strive for the new and unusual, who want to diversify their lives and refuse banal interior items - this is the main group of buyers. Such people follow the news of the modern world and are the first to try its new developments. Also, young married couples with small children buy frameless furniture. They buy such furniture for safety reasons, since there are no corners.

Elderly people will also find frameless furniture convenient, since many of them have a back that is a sore spot. Immersed in it, a person completely relaxes and warms up. An ideal solution for older people.

If you focus on “innovators”, you must understand their psychology. The fact is that such people make choices based on emotions. And they want to receive only unique and non-standard things that no one else has. Therefore, when manufacturing frameless sofas, armchairs, and ottomans, use the principle of exclusivity. That is, each subsequent piece of furniture must differ from the previous one in design. This is not difficult to achieve thanks to the variety of furniture fabrics that are available on the market. Constantly add new styles, experiment with old ones, accept individual orders, and very soon the whole city will know about you, and maybe even more.

How much money do you need to start a business?

Together with the rental of premises (within 70,000 rubles/month), about 450,000-500,000 rubles will be needed to start production of sewing frameless furniture.

You can invest less money if you create production at home, and generally refuse to hire third-party workers at first. In this case, you need to have skills in cutting and sewing covers, and purchase a minimum amount of equipment and materials. This production option allows you to save on renting premises and labor costs, but productivity will be low and the payback of the business will take longer.

Pros and cons of frameless furniture

Like any other type of furniture, frameless furniture has its advantages and disadvantages. The advantages include:

- Convenience and increased level of comfort. The fact is that the filler creates a weightless effect, which makes it possible to relieve tension from the spine and completely relax it.

- Absolute safety. This type of furniture does not have sharp corners, which means children cannot get hurt on them. In addition, the bags weigh no more than 10 kg, so if such an object falls on you, nothing bad will happen.

- High degree of mobility.

- Easy to maintain and highly environmentally friendly. The fact is that the materials for the cover or filling of frameless furniture are completely natural. They can be: satin, eco-leather, tarpaulin, genuine leather. The covers on the furniture are removable and easy to clean, and the filling must be replaced every six months. This makes it easy and simple to get rid of dirt, dust and harmful microorganisms that accumulate in it.

- High degree of maintainability. For example, to repair a frameless chair, it is enough to replace the filling or sew up a torn cover.

- The ability to become a memorable feature of the interior, since this type of furniture can have a variety of colors and shapes.

Frameless furniture takes the shape of the body

Frameless furniture is great for children's rooms and corners, as it is safe

Frameless chairs are very light, so you can take them with you anywhere.

Cons of frameless furniture. There are not many of them. Its main disadvantage is the removal of the filler. The fact is that over time, polystyrene foam balls lose their shape and frameless objects begin to “sag.” As a result, you have to replace the filler, which costs money.

The filling of frameless furniture wrinkles quickly, so it must be replenished from time to time

Note! In addition, this type of furniture can not be used in all interiors. In the case when you have a classic or business setting in the room, ordinary cabinet furniture will suit you, and not soft multi-colored balls. In addition, they cannot be used where there is high humidity, as this can cause polystyrene foam and fabrics to deteriorate.

In any case, this option for decorating the furniture should be kept in mind, since frameless furniture can be made with your own hands quickly, simply and is relatively inexpensive. Classic designs require carpentry skills, special tools, as well as very complex drawings and sketches.

The frameless chair has a handle so it is easy to carry

Having mastered sewing bags, you can not only furnish your home with them, but also organize a small production at home. Typically, such furniture is in steady demand due to its originality and simplicity. In addition, it can be moved to another room without any problems or raised to the attic if not needed.

You can sew a bag for a frameless chair with your own hands, for example, from old jeans

What else do you need to know when starting a frameless furniture production business?

The most popular frameless furniture is considered to be a bean bag chair and a chair in the shape of a pear or ball. One seamstress can cut and sew 3 such products per shift. From 5 to 7 kg of polystyrene foam filler is consumed per chair. In a month of work (22 working days), one worker will be able to sew 66 chairs, 5 people will make 330 products. To fill them with polystyrene foam pellets, you will need about 1650 kg of filler and about 4000 meters of various types of fabric for the outer and inner covers.

Each product has a zipper (2 pcs.) sewn into the outer and inner covers. A total of 660 locks are needed.

The best fabrics for sewing

To make a frameless sofa, you will need two bags: an internal one for the filling and an external one, which acts as upholstery. The inner bag is made of durable but breathable material of any color. Ideally, a non-slip fabric is selected - it is easier to make neat, even seams.

The material for the outer cover can be anything: from special raincoat fabric for bean bags to suede, eco-leather and even fur. Basic requirements for the material: wear resistance, the ability to quickly clean or wash. Choose a color based on the shades that predominate in your interior.

Where to find suitable material? Choose trusted suppliers. Bright and high-quality fabrics for frameless furniture are available in the Bosfor Textile store. Here they sell both rolls and pieces from 3 m. Here you can take the necessary raincoat fabric and sew such a bright frameless sofa:

This is the model we are learning to sew at home today.

Should you make the sofa chair a single color or combine several shades in the product?

You decide!

Marketing features of promotion

Protecting your brand from other manufacturers means creating your own logo, trademark and registered trademark. You need to find a way to distinguish your furniture from those produced by other manufacturers.

Advertising is needed to increase sales, and you will have to spend money on it. You need to create your own website through which you can accept orders and advertise your products on social networks, and use all available means of online advertising. You can make flyers with photos and descriptions of manufactured products and distribute them in crowded places.

Features of advertising and target audience

Where do they buy? The main sources in which it is advisable to advertise are the Internet, thematic and general advertising publications, as well as thematic exhibitions of furniture and accessories.

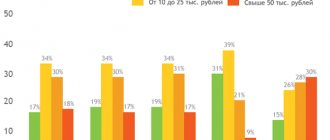

The consumer that manufacturers of frameless furniture are targeting is mainly a young man with an average or above average income, an active user of the Internet and Internet gadgets, fashionable and non-conservative (conservatives prefer traditional furniture). In addition, consumers of bean bags are also young families, both childless and those already having children. The latter is especially important, since bean bags do not have hard and sharp corners that could injure a small child.

Clients who buy frameless furniture have an important psychological feature: they are more focused on realizing their own fantasies, rather than purchasing ready-made mass-produced furniture. That is why the furniture you sew should not be “standard and monotonous”.

Having taken up the business of producing frameless furniture, immediately think through a line, collection, assortment and constantly add new “designer features” to your colorful catalog.

Buying a frameless chair is most often a so-called “impulse purchase.” A person sees a new product well photographed - by a photographer specializing in interior photography - and if he likes what he sees, the person decides to buy. Thus, a separate expense item should immediately include the services of a high-quality interior photographer who will do a photo shoot with your chairs in suitable “glamorous” interiors.

Another option for glamorously presenting your product is to provide your chairs as furniture for local television studios, where especially popular, top-rated programs in the region are filmed. If the studio where the program is filmed is equipped with your furniture, and a lot of people in the region watch this program, then your chairs will become familiar - and this will be the best advertising for their further promotion.

However, what will cost you more – a photo shoot with an expensive interior photographer or promotion on local television – is up to you to decide. But if you have connections on television, be sure to use this chance.

Monthly expenses

| Article | Expenses, rub. |

| Renting premises | 40 000 |

| Communal payments | 8 000 |

| Staff salaries and payments to funds | 283 500 |

| 55 000 | |

| Website promotion | 15 000 |

| Depreciation | 20 000 |

| Total | 421 500 |

Marketing program

Before drawing up a marketing plan, the market for a given product in the region is analyzed, prices and operating features of competitors are studied.

During marketing analysis, the following tasks are performed:

- Market segmentation.

- Study of economic conditions, the relationship between supply and demand.

- Studying the requirements of consumers of this type of service, determining the level of competitiveness of the workshop.

- Analysis of the socio-psychological characteristics of a group of consumers, motivation for decisions when contacting a workshop.

Product policy consists of increasing the competitiveness of the services provided, improving their quality characteristics in accordance with consumer demands, and optimizing the assortment.

The communication component of marketing includes advertising, sales promotion, and service policy. Planning an advertising campaign consists of the following stages:

- Determination of the object (workshop), addressee (consumer group) and motive of advertising.

- Selection of advertising media and their optimal match, schedule of advertising performances and estimates of advertising costs.

Calculation of advertising effectiveness:

| Method | Advantages | Flaws |

| A television | 1. Fully controllable. 2. Quick impact | 1. Very expensive. 2. Selectively. 3. Difficult to convey technical information |

| Magazines | 1. State your goal easily. 2. Simply convey technical information. 3. You can use coupons | 1. Slow advertising. 2. Smaller audience. 3. It's hard to show action. |

| Press (local) | 1. Relatively inexpensive. 2. Good audience coverage | 1. Slow advertising |

| Radio | 1. Quick advertising. 2. Inexpensive | 1. Huge audience reach. 2. It is difficult to show the advantages of the product (services) |

| Posters | 1. Wide audience coverage | 1. Expensive. 2. It is difficult to show the advantages of the product (services) |

| Sound advertising in trolleybuses | 1. Fast. 2. Relatively inexpensive. 3. Wide audience coverage | 1. It is difficult to show the advantages of the product (services) |

As advertising means we choose: billboards in front of the workshop on the streets of the city, advertisements in newspapers, television and radio advertising. The most effective advertising will be a group on social networks.

In parallel with the selection of advertising media, a system of sales promotion measures, a service policy and technical maintenance were developed. Sales promotion measures include discounts.

The service policy and maintenance include home delivery of the product.

Production and prices

Rent a sewing workshop or sew it yourself?

Anyone who is just starting to sew bean bags can get by with a sewing machine and the space of their apartment - there is no talk of any workshop. But as soon as the first numerous orders begin to arrive, the sewing of covers has to be outsourced - orders are given to third-party seamstresses. However, there are pitfalls here - entrepreneurs complain that seamstresses inflate prices for their services, while the quality of their work remains low. After a series of conflicts, the question of creating your own production arises.

However, seasoned entrepreneurs warn: it is not advisable to create your own production of frameless furniture until you have a constant, predictable flow of orders. The way out of the situation is to rent a sewing workshop premises, hire seamstresses of your own selection and constant quality control.

For sewing frameless furniture, the same fabrics are used as for standard sofas and armchairs, so seamstresses will not be forced to retrain while trying to master some new technologies.

Investments and income

Infusions

To implement a business plan for organizing a frameless furniture workshop, initial investments will be required:

| Article | Amount, rub. |

| Registration of individual entrepreneur | 5 000 |

| Marketing | 55 000 |

| Purchase of furniture and equipment | 239 000 |

| Purchasing consumables two months in advance | 350 000 |

| Rent of premises (for two months) | 80 000 |

| Staff salary fund (for 2 months) with payment to the pension fund | 283 500 |

| Total | 1 012 500 |

Costs can be reduced by reducing the number of employees and purchasing used equipment. But this will increase the cost of wages and depreciation, since old equipment will fail more often. The amount of 1,012,500 is borrowed from Sberbank at 18% per annum for two years. The monthly payment is 11,000 rubles.

Planning income

The profitability of the workshop will not be affected by seasonality, so the main factors on which profit depends are traffic and advertising. There are no competitors near the workshop, so 1 master will bring in at least 800,000 rubles per month. And the annual revenue will be from 9,600,000 rubles.

Let's calculate net income by subtracting monthly expenses from revenue:

800,000 – 421,500 = 378,500 rubles. Of this amount, 50% will be spent on the purchase of consumables. Total monthly net income is 189,250 rubles. A small workshop for the production of frameless furniture will generate 2,271,000 net revenue per year.

We calculate profitability:

(189,250 / 1,012,500) x 100% = 18.69%.

Until the entrepreneur returns the main investment, the profit will be divided into the following parts:

- 15% – non-production expenses (payment for delivery of furniture to the client, purchase of household cleaning products, depreciation of equipment, etc.).

- 15% – main fund.

- 40% – early repayment of the loan.

- 30% – entrepreneur’s income.

Since the monthly return on investment will cost 40%, which is 75,700 rubles, we can calculate the return on investment of the project:

1,012,500 / 75,700 = 13.3 months. Taking into account all the risks, the payback of the project is 1.5-2 years.

Payback period

It will be possible to recoup the investment in 4-5 months, but only if all the above conditions are met.

Production premises

To organize a business for sewing frameless furniture, you need to rent a workshop. The area of the room depends on the scale of the project.

For example, in order to install four or five sewing machines you will need a workshop with an area of 25-30 square meters. m. For ten machines – 50-60 sq. m. There are no special requirements for the room, the most important thing is that there is good lighting. In addition, you need a warehouse to store finished furniture.

The storage room must be dry, clean and spacious, since furniture without a rigid base does not fold like regular frame furniture.

Features of the production process

Frameless furniture is made very simply. The design of the bag consists of a lower cover filled with polystyrene foam balls. For the bottom cover, you can use any dense fabric, for example, satin. The choice of fabric for the top cover is unlimited and depends entirely on your imagination.

Faux leather bean bags are the most popular because they do not require special care.

But chairs made of furniture fabric are no less popular. The top cover must be removed for washing; this requires a zipper.

One seamstress can make two or three bean bags in a day. On average, one bag requires about four kilograms of polystyrene and about five meters of fabric for the cover.

Features of frameless furniture models

Before you get to work, you should familiarize yourself in detail with all the features of frameless chairs:

- The design of such furniture does not provide for a rigid frame.

- Depending on the purpose and size of the living space, the chair can be of several sizes in diameter (usually 50 and 100 cm).

- The bean bag chair consists of two covers: outer (removable) and inner.

Note! To sew an outer (removable) cover, velor, micro-corduroy, artificial fur and leather, and linen are usually used. When choosing fabric for the outer cover, it is worth considering the design of the room so that the chair can harmonize with the interior.

For the inner cover it is worth choosing especially durable natural fabrics. Linen material comes in handy: it allows air to pass through perfectly and has a fairly smooth sliding surface. Even used bed linen is suitable for sewing an inner cover.

The most important feature of a frameless chair is that under the weight of a person it takes on the shape of the resting body, which allows you to relax and unwind. While in it, you can read, work on your laptop, watch TV and even take a nap.

Among the advantages of homemade bean bags, the following aspects can be highlighted:

- Original design. You can choose not only the texture and color of the fabric, but also the design of the chair. For example, colorful and bright covers in the shape of a soccer ball or the face of a cartoon character are suitable for a children's room.

- Light weight and easy to transport. The weight of an average-sized bean bag chair does not exceed 8-10 kilograms, so even a child can move it around the house.

- Possibility of use in any interior and outdoors. A comfortable soft chair is perfect for a children's room and bedroom, and will also fit perfectly into the landscape design. The only thing that needs to be taken into account when sewing a chair that will be placed in the garden is that for the top cover you should select waterproof fabrics with high wear resistance.

- Easy cleaning. The presence of a removable top cover allows you to keep the chair neat. You can easily wash the removable cover in the washing machine or use dry cleaning services.

Expert opinions

Entrepreneur Artyom Subbotin, head of the SOFTBAG company, which is engaged in the production and sale of frameless furniture, recently gave an interview to our website, in which he shared his own experience of creating a business for the production of frameless furniture from scratch.

How much did it cost you to implement the idea of sewing and selling bean bag chairs? The entire sale cost me 3 million rubles. And this is only because I immediately wanted to reach the All-Russian level. Otherwise, I could keep the amount to about 20,000 - 30,000 rubles. In this case, I would earn 20,000 - 25,000 rubles. per month, and would pay off in 1-2 months.

Does the frameless furniture manufacturing business have its pitfalls? The biggest pitfall is the production of covers. Decide right away: are you ready to do them yourself? This will cost you about 200 - 300 thousand rubles. This includes investments for small production and the initial purchase of fabrics. There is another way - to order sewing covers from home-based seamstresses or in an atelier. This is the most thorny and unsuccessful path: you will be constantly let down on deadlines, given outright hackwork, inflated prices, etc., and most importantly - a complete lack of commitment on the part of your partner. You can also order ready-made sets of covers. But here, too, the main thing is that they are not made by yesterday’s beginners - home-based seamstresses or ateliers. It is necessary that the patterns are checked, the quality of the stitching corresponds to furniture standards, not clothing standards. This is the nuance that beginners constantly forget about.

What channels do you use to promote frameless furniture? Basically, we promote our products via the Internet, through our website and our blogs. We also use contextual advertising, hold competitions and prize draws, and advertise on social networks. Recently, our website brings us about 200-250 sales per month, which is about 40% of our sales. The rest is corporate orders and dealer sales.

Choosing filling for a bean bag chair

As a filler you can use:

- Polystyrene foam granules (balls) – polystyrene foam. Depending on the size of the finished chair, you should purchase 1-2 packages of 60 liters each. Due to its properties, this material is optimally suited as a filler for frameless furniture. Expanded polystyrene is hygroscopic, light weight, and resistant to high humidity. Foam balls do not absorb sweat and water, and will not retain unpleasant odors.

- Mixed filler, which consists of 70% foam balls and 30% foam rubber. This ultra-soft filler will allow you to feel maximum comfort while relaxing.

- Small wood shavings. This filler should be used for chairs that will be located in a dry, ventilated area.

- Cereals and legumes. As a filler for not too large models, you can use peas, beans, beans, buckwheat, and rice. But it is worth considering that such a filler absorbs moisture and musty air, and also attracts the attention of rodents and insects.

- Rags (old things cut into small pieces). Maybe a bean bag chair will not be light and soft with such a filling, but this option will be the most budget-friendly.

It would not be amiss to add dried stems of lavender, chamomile or mint to the filling - the herbs will create an aromatherapy effect.

Risks and disadvantages of business

Like any other business, the production of frameless furniture is still associated with certain risks. First of all, you need to take care of the quality of the purchased raw materials and supplies, so be sure to ask for safety certificates from suppliers.

Don't skimp on advertising. Despite the fact that competition in this area is still small, the presence of even one competitor in a compact locality that conducts a more competent marketing campaign can cause a drop in demand for the product being sold, and the company will begin to operate at a loss.

Sources

- https://bisnesideya.ru/proizvodstvo/biznes-na-beskarkasnoj-mebeli-plan-kak-nachat-s-nulya.html

- https://xn—-8sbebdgd0blkrk1oe.xn--p1ai/biznes-plan/proizvodstvo/proizvodstvo-beskarkasnoj-mebeli.html

- https://abcbiznes.ru/biznes-idei/216-torgovlya-beskarkasnoy-mebelyu-otlichnyy-biznes-dlya-nachinayuschih.html

- https://Zapusti.biz/biznes-idei/proizvodstvo-beskarkasnoj-mebeli

- https://vipidei.com/proizvodstvo/mebel/proizvodstvo-beskarkasnoj-mebeli/

- https://zhazhda.biz/plan/proizvodstvo-beskarkasnoj-mebeli

- https://www.openbusiness.ru/html/dop7/beskarkasnaja.htm

- https://zen.yandex.ru/media/id/5d32d0bec49f2900b33cccd0/5dce786577c1617acad0a4cd

[collapse]