- Monthly profit (from): $1700

- Payback period (from): 6 months

- Starting capital (from): $10,500

- Business relevance

- Stages of building a business

- Format selection

- Production technology

- Financial plan

- Selection of assortment and material

- Documentation

- Selecting a room

- Equipment and inventory

- Staff

- At home

Format selection

To open a small enterprise, a capital of 600-700 thousand rubles is sufficient, subject to the availability of prepared premises. This amount will be enough to purchase equipment and initial expenses. In this case, the productivity will be 30-50 sets of bed linen per day.

To open a small factory with a capacity of 150-200 sets per day, starting costs will range from 5-6 million rubles. At the same time, you can focus on large wholesale and cooperation with retail chains, which will make it possible to recoup expenses in the first year.

To select a format, it is recommended to analyze the domestic market and select which price category products are in demand.

Product range

The sewing workshop will produce bedding sets of different sizes, as well as individual products. For example, customers don't always buy complete sets; they may only need a pillowcase or just a sheet. This feature must be provided for and reflected in the production plan.

The entire range is grouped according to 3 characteristics:

- By product sizes: 1-bedroom, 1.5-bedroom, 2-bedroom.

- By number of products: ready-made sets and individual products.

- By material: calico, satin, poplin and other materials that the manufacturer is ready to use.

A monotonous assortment does not attract buyers, and the entrepreneur will spend a lot of resources on the development and production of too many items. If we are talking about a small workshop, it is recommended to develop 3-4 positions in each size in the first stages. For example, 3 options for a set made of satin, 3 from poplin, 4 from calico. This approach will allow you to streamline the production process, as well as accurately track which products sell best.

Production technology

Tailoring is characterized by complex processes, unlike bedding, which does not require professional skills. Cutting and processing seams is simple, the main thing is the choice of material and the formation of an assortment range.

The bed linen production technology consists of the following stages:

- placement of patterns on the material;

- cutting according to specified parameters;

- connecting parts, processing seams;

- heat treatment of the product;

- package.

Sewing technology

Standard 2-bedroom bedding set includes:

- 2 pillowcases;

- sheet;

- duvet cover.

The size of the products depends on the type of set - single, semi-size or double. Bed linen is easy to make; it is sewn using standard patterns.

The technology involves the use of special seams - linen or shirt. They are durable and non-elastic, that is, they help the finished product retain its shape for several years.

Before cutting and sewing, the fabric must be processed: this will help simplify the work and avoid shrinkage after sewing, when the size of the finished product is smaller than necessary. The fabric is washed in hot water, steamed and ironed.

Technologies for sewing bed linen are quite simple and accessible even to beginners without sewing education

Sewing sheets:

- Preparation of a rectangular piece of fabric.

- The edges of the piece are folded in 1 cm and hemmed.

Sewing a pillowcase:

- Preparation of rectangular and square pieces of fabric. The rectangular one is 15-20 cm longer than the square one; it is required to “close” the pillowcase.

- Finishing the edges of the pattern (like a sheet), including the closing edge.

- The parts are folded and stitched.

Sewing a duvet cover:

- Prepare 2 rectangular pieces of fabric.

- Process the edges of the cuts.

- Sew the parts of the duvet cover together, leaving a cut for the duvet.

- Sew a zipper into the opening (optional).

Such techniques are used both for DIY sewing and in industrial settings. The only difference is in the speed of production and the division of labor, which is practiced in large enterprises.

Financial plan

To open a mini-workshop for the production of bed linen, expenses of 600-1200 thousand rubles are required. They are necessary for renting and repairing premises, registering a business, purchasing equipment and supplies. How much does it cost to sew bed linen? Fixed expenses will amount to 300-600 thousand rubles and will be allocated to the wage fund, purchase of consumables, payment of marketing, utility, tax and rental payments.

The retail price for one set is 1.2-4 thousand rubles, depending on the calculation of the fabric for sewing bed linen, the wholesale price is from 700-2000 rubles. When selling 800 units or more, the business will pay for itself in six months.

Calculation of business payback

Based on the experience of successfully operating sewing shops producing bed linen, the cost of one set in the middle price category now ranges from 300 to 350 rubles. Thus, with a selling price of 550-600 rubles, the profit from one set of linen will be 200-300 rubles.

When the cost of organizing a workshop with 10 employees is 350-400 thousand rubles (90,000 - equipment and tools, 50-60 thousand - rent of premises, 200,000 - wages in the 1st month of work), in order to recoup the business, you need to sell not less than 2 thousand sets of linen. When calculating the sewing of up to 50 sets by one experienced seamstress in one shift, the business will fully pay for itself in just one month.

Selection of assortment and material

Sewing bed linen can be made from different types of material. The most popular fabrics for bed linen:

- flannel;

- poplin;

- chintz;

- calico;

- cotton;

- linen;

- satin

The standard set consists of two pillowcases, a sheet and a duvet cover. Many companies sell all products separately so that the buyer can create a set on their own. Fitted sheets and children's bedding are also popular.

Master class on sewing bed linen:

Business organization

Organization of production for sewing bed linen consists of the following stages:

- drawing up a business plan with calculations;

- development of assortment;

- collecting a customer base, concluding the first supply contracts;

- selection of premises, purchase of equipment and raw materials;

- recruitment;

- production launch;

- supply of products, making a profit.

Along with the launch of production, you need to start an advertising campaign, since your goal is to produce high-quality bed linen and sell it wholesale, retail, or all together.

If at the initial stage you work independently from home, then you do not need a large-scale advertising campaign, just post information about yourself on several bulletin boards, create a business card website using the Google my business tool or any other constructor.

We will further consider all the stages of starting a business using the example of opening a small workshop.

Range

You can sew for sale:

- bedding sets for adults, teenage children, babies and newborns;

- individual elements of bed linen: pillowcases, fitted and regular sheets, duvet covers;

- decorative bed linen - pillowcases, duvet covers;

- You can sew branded bed linen to order - for hotels, hotels, recreation centers, medical institutions, child care facilities such as kindergartens.

In size it should be:

- single;

- double;

- one and a half;

- king size for large non-standard type beds.

From materials it can be:

- cotton;

- calico;

- satin;

- batiste;

- chintz;

- silk;

- linen.

Take only high-quality fabrics that are hypoallergenic and pleasant to the touch. Be sure to check if the seller has a quality certificate. In a word, carefully control this issue, since the final quality of your product depends on the quality of the fabric.

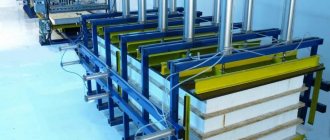

Selection of premises and equipment

For a small workshop, a room of 200 square meters will be enough. Approximately 100 square meters will be occupied by the sewing production itself. Production should be divided into the following zones:

- cut;

- sewing;

- ironing;

- package;

- storage of consumables;

- storage of waste that will need to be disposed of at the end of the shift.

The remaining 100 must be distributed to the warehouse for raw materials and finished products. Separately, you need to take into account administrative premises, a bathroom, and a staff rest room.

Equipment you will need:

- sewing machines;

- overlockers;

- steam irons.

Furniture for the workshop, including organization of workplaces:

- fabric cutting tables;

- the tables on which the sewing machines will be installed will be the seamstresses’ workplaces, so you need to provide them with good lighting;

- comfortable chairs with a backrest, since the seamstress spends most of her working time sitting and this should not negatively affect her health due to an improperly equipped workplace;

- ironing board.

Consumables you will need are scissors, hand and machine needles, thread, pins, centimeters.

Staff

Most seamstresses should have experience. The rest can be hired without experience, gradually being trained in the process of work, if at all there is a need, since at first only 3-4 seamstresses are needed.

You will also need:

- equipment repairman;

- ironers;

- cleaning woman;

- purchasing manager and product sales manager;

- accountant;

- Warehouse Manager.

When starting a business, accounting duties can be outsourced. You can take on the functions of a purchasing or sales manager.

Documentation

To open a mini-workshop for sewing bed linen, you need to open an individual entrepreneur or LLC. OKVED code – 13.92 “Production of finished textile products, except clothing.” The first option is relevant for small companies or home production of bed linen. If you plan to take out a loan or attract investors, it is recommended to choose an LLC; besides, retail chains are more willing to work with these enterprises.

To work, you need to obtain permission from the Fire Inspectorate and SES authorities. This type does not require a special license.

Market analysis

Conducting an analysis of the market and competitors is one of the most important stages for those who do not want to let their business go down the drain within the first year after its organization. Firstly, wholesale companies are not very willing to work with small enterprises, which will be the newly created clothing production.

For retail stores, purchase prices for linen will be quite high. The option of independently selling finished products through your own retail outlet requires much larger investments and time. Therefore, it is necessary to carefully study the local market and competitors in order to choose the right strategy. One of the most acceptable options is trading through an online store, but its creation and promotion also takes time.

But all of the above does not mean that you need to give up on a business even before it opens. On the contrary, we repeat once again that sewing bed linen as a business is one of the most profitable tires in the clothing business today. You just need to be careful about organizing your business.

Selecting a room

A mini-workshop can be rented on the territory of former factories. The size of the production department depends on the number of jobs. In this case, it is worth starting from the calculation of 15-18 m² for two seamstresses, plus every 5 m² for each additional employee.

Each workplace must be equipped with a lighting device; natural light will not be enough. It is necessary to install a ventilation system, since textile dust is considered a fire hazard.

Electricity supply, in addition to household equipment, requires three-phase voltage with mandatory grounding.

As a rule, the premises are divided into a warehouse where materials and finished products are stored and a work area. The latter, in turn, consists of departments:

- cutting shop;

- sewing factory;

- heat treatment zone.

Selecting a room

To organize a sewing workshop, you will need to rent a premises with an area of 150 sq. m. m. A large area is necessary because production requires the presence of several departments: a sewing shop, a cutting shop, an ironing department, a packaging department, a warehouse, a change room and an office for an accountant and managers. The room must be warm, with high ceilings (requirements of the SES and firefighters). If the premises are rented on the second floor or higher, it is advisable to have a freight elevator, otherwise there will be a high turnover of loaders. Renting a premises with all conditions will cost from 80 to 200 thousand rubles per month.

Staff

For the first stage of work, it is enough to hire:

- seamstresses (3-4 people);

- cutters (2-3 people);

- an order taker who will also handle advertising.

It is more profitable to outsource financial reporting.

Sewing bed linen requires basic knowledge and responsibility. It is not necessary to spend money on professional, highly qualified employees or designers. They will be needed for further development and expansion of activities.

Types of products - what to produce?

In small-scale production conditions, the following types of products can be produced:

- Bed linen for adults (duvet covers, pillowcases, sheets)

- Blankets and pillows

- Bedspreads and blankets

- Mattress covers

- Naperniki

- Children's bedding

- Bed linen 3D

It is up to you to decide which products are best to produce. You can produce a specific direction or all at once, but in small volumes. The most profitable area is considered to be the production of children's bedding. But there is also competition in this market segment.

As for materials, the greatest demand among consumers is bed linen made from natural raw materials: cotton, calico, linen and silk. The most popular linen is considered to be made from calico. It is preferred by more than 50% of buyers.

Recently, there has been a fashion for 3D bed linen. Many people buy it and order it online. The bedroom with such linen is transformed. If we manage to bring the technology to perfection, then profit is, in fact, guaranteed.