Hello, dear readers of dohodinet.ru. In Russia and neighboring countries there is a problem of waste disposal and recycling. This niche is currently free, so anyone can become a leader in this area. Knowing how to make money from garbage, you can use a practically free resource to enrich yourself and at the same time bring enormous benefits to the environment.

Making money from garbage is a profitable and promising direction, since this is one of the few unfilled niches in the modern market. If properly organized, the initial investment can pay off in 6-8 months of work, depending on the volume.

Advantages of the garbage business:

- governmental support;

- cheap and sometimes free resource (waste);

- lack of seasonality - there is garbage all year round;

- universality - no need to look for a special target audience, the problem of recycling is relevant for everyone;

- minimum competition;

- high profitability;

- minimal risks;

- an established business can be sold profitably;

- the ability to stay afloat even in the event of an economic crisis.

Industry characteristics

A waste recycling plant is designed for recycling and recycling waste. Typically, such plants can be divided into two broad categories:

- Solid waste recycling (metal, glass, paper and plastic waste);

- Processing of chemicals.

The main task of such plants is to sort materials, separate, for example, metal from plastic, and then further process it.

They are able to restore useful chemicals from already spoiled ones. Accordingly, this industry poses a chemical hazard. The current waste recycling market is not 100% full. This is due to a fairly large amount of waste, the number of which is growing every year. Each person consumes about 250 kg per year. garbage. There are not enough waste recycling plants in every city to process such a large amount of available garbage, so it would be nice if such a plant appeared in every district of the city.

Indeed, this would be of great service to the ecology of the city, but at the same time it would help you make good money from it. Today, not only large cities, but also the villages closest to the city, as well as farms and all individuals need waste processing plants.

A properly drawn up business plan can clearly calculate all planned contributions, while you can calculate mistakes that you can easily avoid. To ensure that your funds do not go to waste, you need to invest them wisely in order to further make a profit. It is also necessary to monitor all events that concern them.

Immediately before opening such a business, it is important to conduct a full analysis of the local market: are there any competitors, their number, how they operate. Choose for yourself the most optimal type of solid waste on which to build your production; it can be plastic or metal. As a rule, this market sector does not contain much competition. But this does not give full hope that running such a business will go smoothly.

But, one way or another, this area of the market is very promising and quickly pays off. To make sure of this, you can carry out a number of marketing manipulations that will help you understand the urgency of the population’s need for this. Based on this analysis, you can definitely decide for yourself whether it is worth opening a waste recycling plant in the proposed area.

Composting

This is one of the most common methods for treating animal waste, solid

household and industrial waste disposal. Its essence lies in the natural decomposition of organic substances during the life of bacteria. There are several technologies.

They consist in the fact that periodically turned over heaps of organic waste are formed on special sites. The tedding of the piles is carried out using special tedding machines. In the most effective version, processing is carried out in special bioreactors with aeration.

However, this method is rarely used in Russia.

In addition, in our country composting is often carried out without preliminary sorting; the resulting compost is dangerous and cannot be used for its intended purpose as fertilizer for gardens, agricultural enterprises, etc.

But even with preliminary preparation it is not possible to get rid of heavy metals in solid waste.

This compost can be used to cover landfills.

Another disadvantage of composting is the need to allocate areas.

High-quality purified compost from organic animal waste (manure and droppings) and plant residues is an excellent source of nitrogen, potassium and phosphorus, which are in a form that is digestible for plants. Composting also destroys helminths and pathogenic microorganisms.

Project implementation

Indeed, a mini-business involves minimal costs for organizing a business, which will avoid large losses in case of failure. But even such a small business requires investment, the size of which can be very large for many. This is due to the fact that the waste processing plant or workshop contains expensive equipment, and the collection and processing process itself is quite expensive.

Otherwise, if you are completely confident in your endeavors or have great support in the form of reliable investors, then it is certainly worth taking action. In this case, in order not to go broke, you should calculate the payback period as accurately as possible and, based on these numbers, distribute the available finances.

If you have already decided to implement the waste recycling plant business plan prepared for you, then you will need to register the enterprise, obtain a license for the right to collect waste and process the collected waste. You can obtain such a license from the Ministry of Environment. The cost of registering an LLC is 10,000 rubles, the cost of a license and additional necessary certificates is accepted as equal to the amount of 650,000 rubles. The license period is four months.

Calculation of investments in opening a waste plant.

| Total | |

| year | |

| Purchase of equipment | 24100000 |

| Working capital | 297500 |

| Organizational expenses | 670000 |

| Total expenses | 25067500 |

Organizational plan for opening.

| Type of work/Month | 1 | 2 | 3 | 4 | 5 | 6 |

| Selection of premises | X | |||||

| Equipment selection | X | |||||

| Conclusion of a lease agreement | X | |||||

| Conclusion of a contract for equipment | X | |||||

| Equipment supply | X | |||||

| Recruitment | X | |||||

| Obtaining a license | X | X | X | X | ||

| Starting a business | X |

Necessary documents for business registration

Legal processing of solid household waste requires obtaining a license from the Ministry of Environment . The Law “On Environmental Expertise” regulates the obligation of each entity that decides to collect and process waste to conduct an environmental assessment. This conclusion can be used throughout the entire life of the company (the approximate cost of this document is 5,500 rubles).

The entrepreneur must obtain permits from services such as fire protection and sanitary, and also stock up on project documentation that will describe all the technological processes of the future waste recycling organization. The total period for collecting and confirming documentation ranges from 2 to 4 months , and the cost is approximately 24,000 rubles .

Choosing a room

First, you need to take care of the premises and territory where the plant itself, the necessary equipment, machinery, as well as equipment and specialized equipment will be located. Such premises can be either purchased or rented, which depends only on your financial situation. Since the business is quite new for you, it is not necessary to immediately aim for a large-scale enterprise. Buying a large amount of equipment and a huge plant itself can be risky for you.

Alternatively, in order to try yourself in this industry, you can set up a mini waste processing plant on rented premises and start your business from there.

The construction or placement of a medium-scale waste recycling plant will not occupy an area larger than 500 square meters. meters. This territory will house production facilities, a warehouse and a garage for equipment. The location of the waste recycling plant should be located only outside the city limits or in an industrial zone.

We are planning to open a similar plant near a small town, where rent is cheaper and the administration is more loyal. The ideal location of such a plant would be an area near a landfill, as this would minimize the cost of waste delivery.

We plan that the area of the production facility, where the equipment for waste processing will be located, is 200 square meters, a 100 square meter area for storing products, and also requires premises for management, a staff rest room and other utility rooms. The total area required for the planned business is 400 square meters.

The cost of renting the premises and renting the adjacent territory is 70,000 rubles per month. We plan that there will be no additional expenses associated with repairing the premises or supplying the necessary electrical power.

How to register a waste recycling plant?

Most likely, this will be an LLC, registered as a legal entity, since it involves the presence of partners in the business and the investment of large amounts of money. To open a plant you will need a number of permits:

- Entrepreneur registration card.

- Statement of registration status with the tax office.

- Permission from the land department to use land for a plant, in case of its independent construction, or for renting a plot of rented premises.

- Permission from the sanitary and epidemiological station.

- Fire supervision permit.

- Permission from the regional environmental center.

- Electrical inspection permit.

for 550 rubles, from our partners, with a quality guarantee.

Choosing equipment

Equipment for such purposes is quite expensive, but you can also save on this if you give preference to a domestic manufacturer. The main technical means include: specialized crushers capable of grinding household waste, waste sorting lines, a press, a storage bin, an industrial magnet, a loader.

The cost of the equipment is expected to be 20 million rubles, including delivery and installation.

To transport garbage for sorting and further disposal of household waste, you will need a Kamaz-based garbage truck. The cost of purchasing a garbage truck with a body capacity of 16 m3 will be 3,700,000 rubles.

A garbage truck with a body volume of 16 m3 can transport up to 8 tons of household waste. In our calculations, we assume that the car transports 6 tons of household waste per trip. You can rent a garbage truck. The cost of renting a garbage truck is 1000 rubles per hour. It takes 8 hours for a garbage truck to do all the work in a day. Renting a garbage truck for a month will cost 160,000 rubles.

It is imperative to install video surveillance not only at the entrance, but also in the room itself where waste is sorted. Also, at the entrance, in addition to the guard booth, it is necessary to install equipment that measures the radiation level of brought garbage. The cost of other equipment including installation will be 400,000 rubles.

In total, it is planned to spend 24,100,000 rubles on equipment, mechanisms and KAMAZ.

Efficient production organization

Suitable premises are a very important stage, because for waste processing production you need at least 600 m2, for a processing workshop - 300-400 m2, and for a warehouse - 200 m2 .

In addition to buildings and structures for industrial purposes, it is necessary to allocate space for administrative premises, which can be located both on the production site and outside it. By the way, workshops located next to the city landfill will help reduce costs both for the delivery of raw materials and for renting premises. The minimum equipment package should include:

- sorting line;

- storage bunker;

- crusher;

- magnet;

- bake.

Additional equipment is a melting furnace, but it is worth considering that it will significantly increase the cost side of the project.

Domestic equipment is considered the most affordable and functional.

State

The main labor at a waste recycling plant is manual labor in the form of laborers and technicians who know their job. It is better to recruit professionals, since the entire production of the enterprise will be built on their abilities and skills. But the enterprise must also have an accountant, a security guard and a cleaner on its staff, the number of which will depend directly on the scale of the plant.

Sorting workers work in two shifts, 6-hour shifts. Accounting and reporting are outsourced, cost 5,000 rubles per month. Security – services of a private security agency. The cost of the private security service is 70,000 rubles per month.

| Qty | Salary | Total | |

| Human | rub/month | Payroll | |

| Director | 1 | 25000 | 25000 |

| Master | 1 | 25000 | 25000 |

| Workers sorting garbage | 36 | 9000 | 324000 |

| Driver | 1 | 20000 | 20000 |

| TOTAL | 39 | 79000 | 394000 |

General payroll and calculation of taxes on it.

| Total | Total | |

| 1 year | 2 year | |

| TOTAL PAYROLL | 2833000 | 4728000 |

| TOTAL TAXES | 849900 | 1418400 |

Recycling of cullet

Broken glass is the basis for a good business. Collecting glass shards “at retail” is inconvenient and unprofitable. It’s easier to come to an agreement and pick up the broken glass at the factory (there is always a lot of such “good” there). It makes sense to think about organizing special reception points.

How to prepare cullet for recycling? It needs to be collected, cleaned and crushed using special equipment. Recycling plants melt and filter the crushed glass.

Finished raw materials are bought, for example, by a manufacturer of glass products. Remelting a “semi-finished product” requires a lower temperature than making glass from scratch. Melting furnaces operate in a gentle mode, which saves a lot of energy.

In addition, recycled glass cullet is readily purchased by companies producing insulation, bricks, tiles, ceramics and abrasives.

Profit and payback of a waste processing plant

The developed business plan must contain all planned expenses for the organization, as well as for the entire production process. Such a complexly organized business does not guarantee payback in the first months of its operation. You will be able to return the invested money in at least a year, and in some cases it may take several years. The payback period depends on the efficiency of the enterprise. But the invaluable advantage of such a business is its reliability.

The planned plant processes 50 tons of household waste every day. Waste is accepted for processing for 670 rubles per ton. The average trash bin near a multi-story building looks like this, containing polymers, food waste, paper and cardboard, rubber, metal, textiles, construction waste and wood. The central place among household waste transported to a landfill is paper, cardboard and food waste (61.5 -73.7% of the total mass).

Let's calculate the average cost of sorted waste. Thus, the cost of an aluminum can per 1 kilogram is 30 rubles, waste paper is 3.5 rubles per kilogram, and pressed polyethylene bottles and polymers are from 7 to 15 rubles per kilogram. Conventionally, we assume that 7.5 tons of waste are sorted per day; the average cost of sorted waste is 5 rubles per kilogram.

Projected revenue for a waste recycling plant.

| Total | Total | |

| 1 year | 2 year | |

| Revenue from waste sales | 5250000 | 9000000 |

| Revenue from waste collection | 4690000 | 8040000 |

| Total revenue | 9940000 | 17040000 |

List of variable and fixed costs.

| Total | Total | |

| 1 year | 2 year | |

| Fixed expenses | ||

| Wage | 2833000 | 4728000 |

| Payroll taxes | 849900 | 1418400 |

| Rent | 770000 | 840000 |

| Depreciation | 4016667 | 4820000 |

| Accountant services | 50000 | 60000 |

| Variable expenses | ||

| Spare parts, consumables | 135000 | 180000 |

| Workwear | 234000 | 312000 |

| Communal expenses | 350000 | 600000 |

| Cost of diesel fuel | 259000 | 444000 |

| Cost of private security company | 700000 | 840000 |

| Insurance individual entrepreneurs | 0 | 0 |

| Other variable expenses | 275000 | 300000 |

| Total costs | 10472567 | 14542400 |

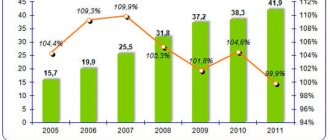

In the calculations we made, it turned out that the business would pay off in four years, and the profitability of the plant was also obtained with a planning horizon of 2 years.

| Planning horizon | 2 years |

| Enterprise revenue, rub. | 26980000 |

| Enterprise profit, rub. | 1690801 |

| Investments in the project, rub. | 25067500 |

| Payback period, months | 47 |

| Profitability,% | 6,3 |

Tire recycling

Disposal of old tires occurs in one of the following ways. For example, “bald” tires can be burned. Or bury it in the ground “waist-deep” in the courtyards of high-rise buildings. By the way, such ugliness can only be found in the courtyards of the former USSR.

Neither one nor the other method suits us. Firstly, it is harmful to the environment. And secondly, such barbaric disposal will not bring money.

There are two “paid” options for making money by recycling tires at home:

- Grinding into crumbs. In cities, crumb rubber is used as a filler for soft surfaces on playgrounds and sports grounds.

- Pyrolysis (or depolymerization). In a nutshell: pyrolysis decomposes rubber into gas (analogue of natural gas), carbon black, synthetic oil and raw materials for metallurgy (steel cord)

In fact, each of the four components is a sought-after raw material that can (and should) be sold.

Conclusion

For some people, such a business may seem very dubious in terms of making a profit, but such stereotypes are built only from ignorance of the essence of this business. If we start from the fact that such a business is commercial, then there is profit. Earnings mainly depend on the type of waste processed (plastic, paper, glass, metal, textiles, wood). If your production is based on chemical waste, then as a result you will be able to obtain materials of an industrial and construction nature. If production is based on recycling electronic waste, then the result is non-ferrous and ferrous metal, as well as glass.

Thus, the main income depends on the waste you choose, which you can recycle, and as a result get clean material. Having established sales, you will be able to receive income, which can only increase as your business develops.

Moreover, with the positive performance of the enterprise, this income can double, triple, and so on. And with a competent approach to organizing a project, it is even possible to organize the processing of sorted waste, which will again increase profits.

Paper recycling

Unfortunately, paper cannot be recycled indefinitely. It can withstand no more than 3-5 cycles. But, despite this, the “waste paper” market is still far from saturation.

Most often, manufacturers use simple (or wet) technology:

- Using a water pulper, paper dissolves in water

- Using a cyclone cleaner, all foreign objects are removed from it

- If cardboard is recycled, a thermochemical processing stage is added

- The finished mixture is filtered through a sieve (fine purification)

Two-thirds of recycled paper is used to make toilet paper and packaging board. But sometimes such raw materials are used in the production of roofing materials.

Features and benefits of business

Opening a waste recycling plant has a number of advantages:

- Stability. Cities produce tons of garbage every day; there will always be demand for the enterprise.

- Financial assistance from the state. The state provides benefits, you can get a grant for opening or take out a loan at 0%. There are also special conditions for paying taxes, since the plant will do something useful for society and the planet.

- Recycling waste and making useful products from it. Selling processed raw materials and ultimately making a profit.

- Small number of staff. To fully operate the plant, a small staff of specialists will be required, which will significantly affect costs.

- Competition. It is simply missing; you can successfully run a business for years without even thinking about the emergence of competitors.

Disposal of household waste - methods

Disposal of household waste is carried out at special landfills (specially equipped sites). There are various technologies for waste disposal, most often compaction is done with a bulldozer. Among the advanced technologies are waste sorting (ferrous and non-ferrous metals, plastic, etc.) and waste compaction using industrial presses. The waste is formed into briquettes and buried in the ground. Subsequently, it is possible to extract “bio-gas” (mainly, the decomposition of organic matter releases methane, a flammable gas).

The most common method for recycling a lot of waste. It is used for non-combustible waste, as well as waste that releases hazardous substances and gases during the combustion process.

Landfills for solid waste disposal, in most cases, use protective systems to prevent pollution and monitor the condition of air, soil and groundwater.

Of all the methods, this is the least expensive, but despite numerous protective systems, it has a serious drawback - it is impossible to completely get rid of air, soil and water pollution.

Type: waste composting. A method of recycling organic substances and their derivatives using a natural process - decomposition. There are not many factories specializing in this type of processing. Basically, this method is used in private households. This is the well-known compost pit. The result of recycling using this method is compost used to fertilize the soil.

Before burning or burying, it is advisable to sort the waste. This process can be partially automated using a conveyor.

Incineration of household waste Produced in special waste incineration plants. Partial sorting is preliminarily carried out - metal is extracted using electromagnets, etc. Forced injection of air and/or oxygen and complex treatment facilities for coarse and fine purification are used.

Variety: plasma processing. Processing using high temperatures. Organic waste, under the influence of temperatures up to 5000 °C, turns into a gas that is safe for living beings and dissolves in the air, and inorganic waste into light glassy slag. This method is very effective, as it allows not only to completely recycle waste, but also to benefit from the heat generated during the recycling process, makes it possible to generate electricity, and the produced slag is used in construction.

At the dacha, a lot of chemicals, insect baiting agents, residues of liquid for fire-bio-protection, etc. accumulate. Can they be poured into the ground?

Chemicals are considered hazardous waste and their disposal often poses an environmental or health hazard. People who improperly dispose of hazardous waste in the trash, in sewers, or in the ground can contaminate water and soil.

What equipment to choose for production

The production will consist of a mobile waste processing complex MMK-100-“N”, costing 4.2 million rubles.

The module is installed on a flat surface (for example, made of concrete slabs) and does not require the construction of a foundation. The length of the complex is 20m and the width is 12m. The plant includes the following components: jet skis, dispensers, an agglomerator, a briquetting press, a sorting conveyor, a magnetic drum, a container for collecting metal, a control panel, a screen, a food waste grinder, a mineral grinder, and a feeding conveyor. The plant consumes only 7 kW.

Business plan for a waste recycling plant

Based on strategic considerations, the company's main goal is to capture the market for polymer raw materials in the Khabarovsk Territory and other areas of the Far Eastern District.

A successful solution to this problem will allow:

- quickly enter a competitive environment and gain your market share;

- create a positive image of the enterprise as a reliable partner that takes into account the various needs of consumers;

- ultimately ensure a stable sales volume and receive a guaranteed profit.

The company's sales strategy is to create long-term sustainable relationships with enterprises that use secondary raw materials for their own production and reorientation of enterprises that use primary raw materials to secondary raw materials. This approach is dictated by the fact that secondary raw materials are a very specific product.

Also, the presence of stable ties makes it possible to guarantee the sale of raw materials and subsequently makes it possible to create a dependence of the manufacturer on the supplier of raw materials, which, in turn, makes it possible to manipulate the price within a much wider range than with free sales.

The practical absence of competition in the production of secondary raw materials determines the only factor limiting the selling price is the prevailing prices on the market. This circumstance makes it possible to enter the market with products, the price of which is set 3-5% lower than the existing ones, and after establishing stable connections (creating dependence of the manufacturer), gradually increase the price to the maximum possible (taking into account the production characteristics of a particular consumer).

Taking into account the real need of producers for raw materials and the significant price advantage compared to primary raw materials, sales are expected to be carried out only on the basis of 100% prepayment. Also, (at least for enterprises in Khabarovsk) it is possible to introduce conditions for pick-up of raw materials from the seller’s warehouse, which will make it possible to reduce the value of the transport component of the cost.

In a situation where demand exceeds supply many times over, we can say with confidence that the products manufactured by the company will be in demand and their sales (especially if the strategy of concluding direct contracts with consumers of the products is chosen) will be guaranteed.

The current situation does not require significant advertising costs, however, in order to gain a stable position in the market, inform potential customers about their products and maintain stable long-term relationships, the following advertising activities are planned:

- Placement of articles about the company’s activities in specialized magazines and newspapers (budget 15,000 rubles per month);

- Printing information booklets, brochures (budget 5,000 rubles per month);

- Making gifts for potential clients with branded symbols (category VIP gifts, intended for potential and existing partners of the company, budget 10,000 rubles per month).

Thus, the planned advertising budget is 30,000 rubles. per month.

The company's pricing policy will be designed to capture the planned market share and the maximum possible sales volumes.

The optimal possible price for the product must fully compensate for all costs of production, distribution and marketing of the product, and also ensure a certain rate of profit. The most common methods for setting prices for goods are:

- based on production costs;

- demand-oriented;

- at the current price level.

It is intended to use the cost-of-production method of setting prices. The essence of the method: a premium is added to the total amount of costs corresponding to the rate of profit accepted in the given industry or equal to the desired income from turnover.

This method is also called the “average cost plus profit” method. The product price is calculated using the formula:

P = С*(1+ Rп) + Н,

where C is the cost; Rп - percentage of profit (margin); N - taxes (VAT).

To enter the market and gain a position in the market, it is necessary that the price be lower than that of competitors. To do this, we will set a markup from 40% to 60%. In the future, it is possible to increase the trade margin.

The problem of waste disposal in the Russian Federation

In Russia, 5 percent of garbage is recycled, the rest is landfilled. The Russian Ministry of Natural Resources sees prospects for recycling in the construction of waste incineration plants. To what extent will these measures solve the problems of environmentally friendly disposal? The question remains open.

Not all landfills are suitable for their intended purpose and do not provide a reliable degree of environmental protection from leaks of harmful emissions into surface and underground waters.

Garbage is not even buried, fires break out in landfills, toxic combustion products spread to residential areas, harming flora and fauna. In addition, they become sources of the spread of infectious diseases.

City landfills are located in a suburban 10-15 kilometer zone. And given the fact that new developments are taking place on the outskirts, they end up close to the city limits.

Disposal of industrial waste - methods

Neutralization Various techniques and methods to reduce the danger of waste to the environment. An example is grinding waste mercury lamps and treating them with a solution of potassium permanganate or ferric chloride. They neutralize medical and biological waste and thermometers. After neutralization, the waste can be buried. Also used for alkalis and acids.

Disposal Used for waste of hazard classes 4-5. Examples are overburden from mining operations, waste from processing industries, etc. Burial takes place at special landfills. Use Many types of industrial waste are subject to further use. For example, ash and slag waste is used in road construction, overburden rock is used in backfilling goafs (mines), waste oils can be used to lubricate mechanisms, etc.

Incineration The method is used, as a rule, for waste of hazard class 3-4 (oily rags and sawdust, waste from the woodworking industry, etc.). Combustion equipment is subject to fairly stringent requirements - pipe height, forced air supply, etc. A project must be developed with calculated concentrations of harmful substances during operation of the installation.

Additionally: gas purification.