In the modern world, the demand for products grown in personal plots is growing.

In order to garden commercially, heated greenhouses are required.

Not every entrepreneur wants to spend time and effort on independently manufacturing such structures.

Most gardeners prefer to purchase or order ready-made greenhouses, and a business idea for the production of greenhouses will help them with this.

Business in the production of equipment for farms, gardens and vegetable gardens is considered very promising.

One of the areas of such commercial activity is the production of greenhouses.

Polycarbonate structures are in greatest demand, since this material retains heat well without transmitting ultraviolet rays.

In addition, the cost of polycarbonate greenhouses is relatively low.

Business Features

Entrepreneurs who consider the manufacture and sale of polycarbonate greenhouses as a promising business are attracted to this type of activity primarily by the low capital intensity of production and the high liquidity of the equipment used: it is enough to invest 170–200 thousand rubles in the purchase of ordinary power tools and find suitable suppliers of fairly common building materials.

Demand for greenhouses peaks in early spring and late fall. Therefore, it is best to start implementing this business idea 2021 with minimal investment in rural areas at the end of February in order to develop a sufficient client base by the beginning of the season. As for the cold season, greenhouses and various winter gardens become in demand at this time. Due to the structural complexity, the cost of such structures is several times higher than the price of standard greenhouses, however, their construction requires a certain amount of experience and skills: this is where the knowledge accumulated in the summer comes in handy.

It is also advisable to learn how to build a thermos greenhouse with your own hands for winter growing: such designs are in demand among farmers and entrepreneurs who are engaged in floriculture or cultivating crops such as green onions, dill, parsley and strawberries throughout the year.

The business has a profitability of 100–120%, but that is why it is quite difficult to find a free market niche: in large cities, supply significantly exceeds demand. The solution can be either the formation of competitive advantages that are interesting to the consumer (price promotions, warranty support, short order fulfillment time), or an even narrower specialization - for example, the production of industrial greenhouses. In addition, when developing a marketing strategy, you must always remember who the target audience of the business is:

- Owners of summer cottages and subsidiary plots who are interested in vegetable growing in order to meet their own needs;

- Farmers for whom selling greenhouse products is the main or additional way of generating income;

- Industrial greenhouse complexes covering tens of hectares.

Search for clients

You can make the highest quality and budget greenhouses in the world, but no one will buy them without proper advertising. It is important to understand where your product will be most in demand. You can sell metal structures in dacha villages, dacha cooperatives, surrounding villages, and gardening cooperatives. To popularize your product, use the following recommendations:

- Place advertisements in the media. These could be local newspapers, radio, TV channels. It is advisable to start an advertising campaign in February and not stop until the end of the season. The period of greatest demand for metal structures is in spring and autumn.

- Post several advertisements on the Internet for the sale of greenhouses and greenhouses. Today there are a lot of different sites and platforms where you can do this for free or for a minimal fee.

- Don't forget about message boards. The design of the leaflet itself should be concise, with a description of all the advantages of the products offered, and approximate prices. Indicate on paper contact phone numbers, address, and email. You can design a flyer yourself in any editor or contact an advertising agency for help.

- Agricultural stores. People shopping will definitely pay attention to your leaflets and flyers.

So, to quickly find clients, decide on the competitive advantages you can offer. This can include convenient logistics, installation of a greenhouse or hotbed at any time convenient for the customer, a flexible approach to setting prices for all products, willingness to produce structures of non-standard shapes and sizes, and work in the garden. In winter, when there is practically no demand for greenhouses, you can offer services for the design of winter gardens and greenhouses.

A good prospect for further business development is the production of not only greenhouses, but also the production of balcony canopies and open verandas. Offer your customer a wide range of different services that will be in demand all year round. With this approach, you will increase the flow of customers, and the profitability of the production of greenhouses and other structures will increase significantly.

How to accept an order for the production of greenhouses

To provide a quality product to the client, it is necessary to understand what the person ultimately wants to receive. It’s easy to understand the client; just ask him a few guiding questions:

- What size should the structure be?

- What crops are you planning to use the greenhouse to grow?

- Will the greenhouse be used during the cold season?

- Where should the metal structure be placed and what are the ways to supply water to it?

- Is there a need to install a heating system and automatic watering of plants?

- What is the budget for purchasing a greenhouse?

After receiving answers from the customer, you can offer him several optimal options. Especially regarding the shape of the greenhouse and the material. Immediately discuss with the client the timing of the production of metal structures, discuss the optimal time of day or evening for installation work on the site.

Types and purposes of greenhouses

Regardless of who becomes the buyer of such a greenhouse of their own production, the basic requirements for its design will be approximately the same - durability, strength, adaptability to regional climatic conditions, ease of use and low price.

In addition, when choosing a model, everyone is guided by their own motives. The owner of a site on which a landscape designer has worked thoroughly will be more likely to be interested in a stylish appearance and an original architectural solution, while an entrepreneur who considers growing flowers in a greenhouse as a business will primarily pay attention to the operational characteristics and the possibility of adapting the internal space to specific production requirements. needs.

Preferences are to a certain extent influenced by the list of plant species that are supposed to be cultivated in artificial conditions: for example, to plant tomatoes or grow chrysanthemums in a greenhouse, you need a rectangular structure with vertical walls, since in the first case the bushes are large and do not grow well under arched vaults, and in the second, flower pots are placed in several tiers.

In addition to classification by purpose (seedlings, vegetables and flowers), greenhouse structures are also divided according to shape into:

- Rectangular with a gable roof. The frame of the greenhouse externally resembles a house with walls up to 1.5 m high and a ridge located at a level of 1.8–2.2 m. Thanks to this shape, the owner does not have to bend his head while working, and the vertical arrangement of the walls allows plants to be placed on shelves and shelves. Another advantage of the design is the large slope of the roof: when making greenhouses from polycarbonate, the calculated value of the snow load can be reduced, since the snow will slide down under the influence of gravity;

- Arched. In this case, the basis of the greenhouse frame is arches with a radius of 2–2.2 m arranged in a row. Due to the absence of corners and planes, the structure is characterized by minimal consumption of covering material, good light transmission and high resistance to wind loads, however, snow from horizontal sections of the roof must be removed manually. In addition, the manufacture of arched greenhouses requires special equipment, and therefore it is quite difficult to build such a structure from scrap materials;

- Rectangular with sloping walls. The shape of such a greenhouse is an intermediate option, combining the advantages of arched and gable structures. Due to the fact that the walls are installed at an angle, the useful area of the base increases, and the amount of reflected sunlight decreases;

- Wall-mounted. If the permanent structure (house, barn) is located well, a greenhouse with a pitched roof can be attached directly to its wall: this option allows you to save on building materials and make the most efficient use of the site area. In addition, in some cases, the entrance is arranged directly from the room, turning the structure into a greenhouse;

- Polygonal. Octagonal buildings with a hip roof are constructed primarily for decorative purposes, using metal and glass (less often, monolithic polycarbonate) as materials for making greenhouses. Nevertheless, the design is not without practical advantages: at different times of the day, each of its faces is illuminated by direct sunlight.

Types of greenhouses

A detailed examination of each type of greenhouse and its equipment will allow you to decide on the choice and volume of production.

options:

- Amateur . It is characterized by seasonal use and has a simple design that can be dismantled if necessary. It is used for growing vegetables and fruits in minimal quantities; internal equipment, including automatic watering, is usually absent.

- Farmer's . Designed for use in small businesses, it has a larger volume, is used all year round and can have internal equipment according to the wishes of the buyer.

- Industrial . A large-scale structure, often covering several tens of hectares, which can be used all year round and contains the maximum equipment: automatic irrigation, LED bulbs, thermal drives, pressure sensors, steam generators and a heating system.

Regardless of production volumes, it is necessary to purchase raw materials for the manufacture of polycarbonate greenhouses.

Technology for the production of polycarbonate greenhouses

Step-by-step making of a greenhouse with your own hands is a technologically simple process that is accessible to anyone with minimal experience in handling power tools. Installation of a standard design in this case includes the following steps:

- Construction of the foundation. Construction materials and type are selected based on the requirements and financial capabilities of the customer;

- Making the frame. Using special equipment for the manufacture of greenhouses, the cutting of the main elements is carried out. For processing wood, circular and band saws are used; for cutting and bending profile pipes, metal-cutting and rolling machines are used;

- Assembly of the structure. A frame is assembled on the prepared foundation, which is subsequently sheathed with polycarbonate sheets;

- Installation of additional elements. Work on the construction of a greenhouse is completed with the installation of doors, vents with manual or automatic control, heating and watering systems, shelving, as well as arrangement of beds.

Foundation

The construction of a foundation, including a greenhouse foundation, requires preliminary marking and leveling of the surface of the site. Then, in accordance with the nature of the soil, a specific structure is selected - strip, block, brick or wood. It should be noted that the cost of manufacturing a greenhouse from polycarbonate directly depends on the chosen option: a strip foundation is considered the most expensive and durable, and one made of timber at a low cost requires replacement every 5–6 years. However, each type is characterized by its own advantages and disadvantages:

- Wooden from timber 100x100 mm. In addition to the low price, the main advantages of this type include low weight, accessibility and mobility: if necessary, the structure can be disassembled and moved to a new location. However, despite the antiseptic impregnation, wood in conditions of high humidity and constant contact with the ground becomes unusable after a few years;

- Blocky. Before installing such a foundation, you need to dig a trench around the perimeter of the greenhouse, and then place concrete blocks in it and level them in a horizontal plane. The high cost of the structure in this case is due to the labor intensity of construction and the need to use lifting equipment for the production of polycarbonate greenhouses, which is fully compensated by the service life measured over decades;

- Brick or stone. To lay natural stone or brick, you must either have the skill of a mason or be able to attract qualified specialists to the construction. In terms of cost, such a foundation is the most expensive, and in terms of service life it practically does not differ from a block foundation;

- Tape. A complex and expensive foundation - to build it you need to dig a trench, install formwork, tie reinforcement and pour concrete. Accordingly, making a polycarbonate greenhouse with your own hands requires including a concrete mixer, a welding machine, shovels and a wheelbarrow for transporting earth in the list of equipment. Despite the high cost, this solution is one of the most popular due to its reliability, durability and the ability to obtain a perfectly flat base.

Frame

When making a polycarbonate greenhouse with your own hands, to assemble the frame, you can use any materials that have sufficient strength - rolled metal, wooden beams, plasterboard profiles and even polypropylene pipes. However, despite their lightness and low cost, the last two options in mass production are quite rare - the domestic buyer prefers more solid structures:

- Wooden frame. In addition to low thermal conductivity, this option is characterized by ease of installation and ease of processing of elements - to make a wooden greenhouse, it is enough to have a hacksaw and a screwdriver at your disposal. All elements are assembled on corners and screws, and then treated with antiseptics or drying oil. Significant disadvantages of a wooden frame are its high price and fragility;

- Steel frame. The basis of this design is rolled metal - an angle, a channel, a square or rectangular pipe. To make a greenhouse from a profile pipe, it is advisable to use galvanized elements, since at high humidity, even annual repainting does not save the metal from corrosion. The main advantages of a steel frame are durability and practicality, while the disadvantages include increased thermal conductivity, the presence of thermal deformations (which is especially important in the manufacture of large industrial greenhouses) and the complexity of installation: mainly welding or bolted connections are used for assembly.

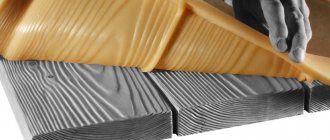

Coating

Due to its low thermal conductivity, high strength and reasonable price, cellular polycarbonate is the optimal material for making a greenhouse. This thermoplastic with a thickness of 3.5 to 10 mm is produced in sheets 2.1 m wide and 6 or 12 meters long: when designing a structure, it is advisable to take these dimensions into account to avoid waste.

The only drawback of the material is high temperature deformation, reaching 5 mm per meter of length (taking into account the difference between winter and summer temperatures). Therefore, to fasten sheets, special connections are used that allow some mobility of the polycarbonate relative to the frame:

- Plastic thermal washers. The large diameter (33 mm) and the presence of an elastic sealing ring allows this fastening element to reliably hold the sheet even in strong winds, and the cap provided by the design protects the screw head from corrosion;

- Detachable or one-piece H-profile. In this case, the profile itself is attached to the frame, and the sheets are inserted into its side grooves and held there by friction. This greenhouse production technology requires precise calculation of thermal gaps to avoid polycarbonate falling out of the profile in winter and “swelling” in summer;

- Galvanized tape. The sheets are laid overlapping on the frame and pressed at regular intervals with a tightly stretched steel tape. It should be noted that this method of fastening can only be used in arched structures.

Polycarbonate has open honeycombs, into which not only dust and dirt, but also various insects easily fall. To protect the ends of the sheets, all joints are sealed with perforated plastic tape, and the lower edges are additionally protected with U-shaped end caps.

Greenhouse manufacturing technology

The two main components of any greenhouse are the frame and the cover. Previously, the base was made of wood, and the entire structure was covered with film or glass. Today there are modern materials that can make the conditions in the greenhouse more acceptable for plants. The design itself is quite light and mobile. An example of such a material is polycarbonate.

The parts are connected using a welding machine. They are customized and painted. The installation of polycarbonate most often occurs in the area where the greenhouse is installed. In the workshop, you need to provide all the small details: fasteners, fittings, slots for vents, and more.

An important factor in the manufacture of greenhouses is its design. It must be taken into account that the distance between the arcs and the number of horizontal guides determines what snow load the finished product can withstand. The time and quality of installation of the structure on site depends on how accurately all the details are completed in the workshop.

Polycarbonate production

Polycarbonate can be purchased ready-made from the manufacturer, or you can organize your own production. Then it will be possible to expand the range of your products and even make industrial hydroponic greenhouses. A polycarbonate production line is complex equipment. It consists of the following units:

| 1 | Extruder with vacuum degassing system and power unit. |

| 2 | Pumps for melting raw materials. |

| 3 | Flat slot head. It is equipped with a set of replaceable filters. |

| 4 | Calibration devices. |

| 5 | Pulling device with knives for longitudinal cutting. |

| 6 | A storage line that is 5 meters long. It is equipped with a pneumatic drive and a cutting device. |

The cost of such a line starts from 650 thousand rubles. The price depends on the power of the extruder, the speed of drawing the workpieces and the performance of the pulling device. Modern lines make it possible to produce high-strength plastic, which is in demand in the production of greenhouses.

Room

As a business, the production of greenhouses on a wooden or metal frame does not require a large premises: the final assembly of the structure and cutting of sheets is carried out exclusively on the customer’s premises. You can even carry out one-time orders in your own garage if you install a machine for making polycarbonate greenhouses here, however, as the scale of the enterprise increases, the need for territory for storing raw materials and finished products inevitably arises. Therefore, at a certain stage of business development, you will have to look for a workshop that meets the following requirements:

- Total area - from 40 m² including storage facilities;

- Ceilings 3.5–4 m high up to the ceiling;

- Connection to electrical networks with voltage 220/380 V;

- Heating available for winter use.

In large regional centers, such production space can be rented in industrial zones at a rate of 200–250 rubles/m² per month.

Equipment purchase

At first, you cannot do without a manual pipe bending machine, a pendulum cutting machine, a welding machine and a professional jigsaw. It would not be amiss to include in the expense item the purchase of a drill, a screwdriver, a set of wrenches and various measuring devices (protractor, caliper).

If you offer greenhouse installation services, you will have to go to the client with equipment. Therefore, it makes sense to start looking for a car. The ideal option is a Gazelle or any other vehicle of this size. You can rent a car.

Equipment

Organizing a business in the production and sales of polycarbonate greenhouses involves the purchase of not only power tools, but also specialized equipment designed for working with rolled metal. For example, making an arched-type greenhouse with your own hands from a profile pipe requires a special pipe bending machine: depending on your financial capabilities, you can choose a low-performance model with a manual drive, or a more powerful version with an electric one.

A concrete mixer, shovels and wheelbarrows for earth are used in the construction of strip and block foundations, and a welding machine is used in assembling the frame and tying reinforcement. To save on transport services, it is advisable for an entrepreneur to also have a car at his disposal for transporting equipment, frame parts and polycarbonate sheets.

Equipment list

| Name | price, rub. |

| Angle grinder (grinder) | 2500 |

| Roll forming machine for greenhouse production | 56000 |

| Pendulum cutting machine | 21000 |

| Concrete mixer 200 l | 13000 |

| Welding machine | 7000 |

| Cordless screwdriver | 3500 |

| Aluminum ladder | 2500 |

| Drill | 4000 |

| Jigsaw | 3500 |

| Measuring and marking tool | 4000 |

| Consumables, drills, abrasive discs | 2000 |

| Hand tool | 5000 |

| Total: | 124000 |

What actions to take to open a business

First of all, study the market well, become familiar with the products that competitors offer. Based on the information received, draw up a business plan. This software product helps to identify target markets, estimate production costs, formulate company goals, and calculate profit levels. Only after this take the following important steps, namely:

- individual entrepreneur registration;

- search and rental of a workshop;

- purchase of consumables and equipment;

- conducting an advertising campaign, searching for employees (if necessary at first).

Registration is a fairly quick process, taking 4-5 days. To contact the authority, make a photocopy of your passport and be prepared to provide a receipt for payment of the fee. After this, open a current account in any bank and register with government agencies.

NOTE. When registering an individual entrepreneur, you will need to indicate OKVED - the code assigned to your type of activity. For a greenhouse manufacturing company, choose OKVED 25.11, which is located in section C.

Individual entrepreneurs often find it difficult to choose a tax system. In this area of activity, it is better to give preference to the simplified tax system (simplified taxation system). There are two options: either you pay 6% of income, or you give 7% of net profit (depending on the region of registration of the legal entity).

What other documents may be required in order to start making greenhouses? There is a misconception that to start working you need to obtain a license and permission to do business. At the initial stage, a certificate of registration of an individual entrepreneur will be sufficient.

Financial investments and profits

When calculating the volume of initial investments, an entrepreneur needs to take into account not only the costs of purchasing equipment for the production of greenhouses, but also the costs of conducting an active advertising campaign. Developing your own website can be a successful way to attract customers: buyers often study the prices and characteristics of products from different manufacturers on the Internet.

Initial Investment

| Name | Amount, rub. |

| Equipment | 124000 |

| Enterprise registration | 2000 |

| 20000 | |

| Site development | 25000 |

| Unexpected expenses | 15000 |

| Total: | 186000 |

The amount of current monthly expenses is determined primarily by the size of staff salaries. Of course, at the initial stage, you can start making greenhouses yourself, but as the flow of customers increases, you will have to additionally hire two installers to assemble the products, and one craftsman to work in the workshop.

Current monthly expenses

| Name | Amount, rub. |

| Fare | 10000 |

| 8000 | |

| Wage | 45000 |

| Insurance premiums for employees | 13500 |

| Insurance payments for individual entrepreneurs | 2300 |

| Renting premises | 8000 |

| Communal payments | 2000 |

| Administrative expenses | 3000 |

| Total: | 91800 |

To calculate the profit from the manufacture and installation of polycarbonate greenhouses to order or for sale, you need to draw up a detailed estimate, including the cost of purchasing material and fasteners, as well as the cost of all related work.

Niche analysis and target audience

At the beginning of your journey, decide who the production will be aimed at and which greenhouses are more profitable to produce in your area of residence.

The scale of the business, the cost of equipment and the attraction of additional labor depend on this. Target audience for polycarbonate greenhouse business:

- Owners of summer cottages, residents of rural areas who grow fruits and vegetables for their own needs or small sales.

- Farmers with greenhouse complexes, representatives of small businesses, gardening partnerships.

- Large industrial greenhouse companies with high turnover.

Depending on the application, the types of greenhouses and their equipment differ, and from these factors comes the increase or minimization of costs for the manufacture of polycarbonate greenhouses.

Estimate for the production of a greenhouse 3x6x2.2 m

| Name | Qty | price, rub. | Amount, rub. |

| Galvanized profile 20x20x2 mm | 98 m | 102 | 9996 |

| Polycarbonate 2.1x6 m | 4 things. | 1650 | 6600 |

| Connecting profile | 12 m | 50 | 600 |

| End cap | 12 m | 42 | 504 |

| Perforated tape | 26 m | 16 | 416 |

| Roofing screw 5.5x25 mm | 300 pcs. | 1,2 | 360 |

| Polycarbonate thermal washer | 300 pcs. | 5,7 | 1710 |

| Loops | 8 pcs. | 20 | 160 |

| Total: | 20346 | ||

| Foundation | |||

| Tape | 18 m | — | 8000 |

| Blocky | 18 m | — | 5300 |

| From timber 100x100 mm | 18 m | — | 1200 |

| Price for strip foundation: | 28346 | ||

| Price on a block foundation: | 25646 | ||

| Price for a timber foundation: | 21546 | ||

The market value of such a product without a foundation is at least 25,000 rubles, and the profit from its sale is 4,654 rubles. It should be noted that with large production volumes, the price of the greenhouse can be further reduced by receiving a wholesale discount when purchasing profiles, polycarbonate and hardware.

Profitability and profit calculation for greenhouse production

Greenhouses are currently purchased all year round, because many summer residents want to see only fresh vegetables or fruits on their table. There is a special demand for the product in the spring, especially if there is already an established customer base.

According to our calculations, the cost of a greenhouse complex measuring 6*3*2 is approximately 18,000 rubles. The cost of such a structure on the market is from 25,000 rubles.

However, this calculation does not include installation services. As a rule, in order to install a greenhouse, the client must pay the same amount as for the structure itself. You will have to pay separately for delivery if the greenhouse needs to be moved further than 30 kilometers from the place where the goods are sold.

As a result, from one order you can make a profit of 30-40 thousand rubles. Just a few orders - and you will be able to recoup the costs of purchasing equipment, and then receive a net profit.

As you can see, the production of greenhouses will pay off after just a few orders, especially if you make them in your yard without the help of hired workers. Over time, using business profits, you can buy powerful equipment and open a large-scale workshop that will produce greenhouses for the whole country.

Materials taken from the source: biznesprost.com

Construction works

| Name | Qty | price, rub. | Amount, rub. |

| Greenhouse assembly | 1 PC. | 6500 | 6500 |

| Laying strip foundation | 18 m | — | 10800 |

| Laying a block foundation | 18 m | — | 5600 |

| Laying a timber foundation | 18 m | — | 2000 |

With a continuous flow of customers, four people (including the owner of the business) can manufacture and install up to 15 arched greenhouses within a month. Income in this case is determined not only by the size of the product itself, but also by the type of foundation.

Search for buyers

One of the most important issues in any type of business is the sales market.

When it comes to a greenhouse, a business can be developed by targeting gardeners and gardeners. Inexpensive polycarbonate structures are in greatest demand among them. But here it must be said that competition in the production of such greenhouses is quite high, so it is better to expand the range in order to increase the number of potential customers.

It is advisable to check the presence of competitors and the occupancy of a given niche in a particular locality before investing money in this enterprise. To do this, you can look through newspapers with advertisements, pay attention to poles and bus stops, which are usually full of such advertisements. By the way, the above methods are the best means for announcing your business to the whole world. Advertising materials can also be placed in stores that specialize in selling seeds and garden equipment, and on the Internet.

If you produce greenhouses, business involves finding customers, so you need to show people that your work is the most profitable and attractive offer compared to competitors. All this must be described in advertising leaflets. Examples include speed of operation or ease of delivery. A good marketing move, especially at first, would be a system of discounts that can be offered to regular customers or to those who “refer a friend.”

Well, one of the important steps, without which a greenhouse business will not be legal, is the procedure for registering a businessman with the tax authority. You will first need to select a suitable tax system. In this case, any of those allowed for individual entrepreneurs will do. It is advisable to choose an option with a minimum number of accounting reports, so as not to be distracted by paperwork and focus on the quality of the products produced.

Income depending on the type of foundation

| Name | timber | Blocky | Tape |

| Income from the sale and installation of a greenhouse, rub. | 13154 | 16754 | 21954 |

| Monthly income, rub. | 197310 | 251310 | 329310 |

| Profit before tax, rub. | 105510 | 159510 | 237510 |

| Net monthly profit, rub. | 89683 | 135583 | 201883 |

| Payback period, months | 2 | 1,4 | 0,9 |

How to accept orders for the production of greenhouses and greenhouses

After posting advertisements closer to spring, we begin accepting orders. Discuss with the client:

- The place where the greenhouse needs to be located;

- The structure will be used all year round or only in the warm season;

- Dimensions (length, width, height);

- What types of crops are planned to be grown;

- What equipment needs to be installed;

- What methods of water supply are available on site;

- What budget do you need to stay within?

Offer several optimal options, indicate production time and installation time.

Advertising campaign

Video on the topic

In order to quickly and reliably recoup the initial investment, you need to start building a client base even before searching for premises and purchasing equipment. If preliminary market research shows the presence of significant demand and the absence of major competitors in the region, you can adjust the list of equipment and purchase, for example, more powerful machines. In general, to find first buyers they use:

- Placement of advertisements and advertising blocks in newspapers and magazines for gardeners;

- Promoting your own website and using the free capabilities of the Internet - publishing advertisements on sites and social networks;

- Posting advertisements and leaflets on poles near dacha and garden cooperatives, as well as in nearby villages and hamlets; negotiations with owners of farm and industrial greenhouses.

We should not forget about the formation of competitive advantages. For example, some manufacturers increase the price of greenhouses within reasonable limits, but include free assembly of the frame or installation of a timber foundation.

Business promotion should begin at the registration stage. Some effective marketing strategies include:

- placement of advertisements in media with a narrow focus - periodicals for gardeners and gardeners;

- advertising on thematic farming sites, forums, groups on the Internet;

- distribution of leaflets, brochures with offers;

- posting advertisements outside the city, near dacha cooperatives, farms, etc.

To attract the attention of the target audience, advertising offers must contain information about the competitive advantages of production - promotions, discounts, guarantees, low prices and other advantageous features of the products produced.

At the initial stage, investments in advertising will average 10,000 rubles.

Equipment for the production of

If you want to start your own greenhouse production, you need to purchase factory equipment. It costs more than 200 thousand rubles. To make structures on a wooden base, you need to hire workers. In this case, the cost of production will increase significantly, but the demand for them remains consistently high.

Equipment for a greenhouse profile will cost 690 thousand rubles. This machine is designed for the production of steel profiles. It is equipped with an automatic control system. This allows you to program the location of the required mounting holes. Using a roll stand, a radius deflection is given to the profile. It is used for the production of arched products.

Scheme: greenhouse production

Features of greenhouses

- Single-pitch or wall-mounted. Most often used for amateur purposes. By attaching it to the south side of the building, you will be able to save on materials and make more efficient use of the territory of your personal plot.

- Gable or hipped. They can stand alone or, just like single-pitched ones, be located along the wall of another structure. Snow and water will not linger on such a roof and damage the covering material.

- Arched. They are distinguished by better resistance to wind and greater light transmission. Due to the absence of corners, less covering material is required. But you will have to remove the snow cap yourself.

Kinds

- Amateur. It is the simplest design. This is a seasonal option. Usually without internal equipment and automatic watering. As a rule, it is used in summer cottages. If necessary, it is not difficult to dismantle or move it to another place.

- Farmer's. Used in small businesses. Larger volume. Can be internally equipped for year-round use.

- Industrial. A large structure can occupy several tens of hectares. Designed for use all year round. Fully equipped (automatic watering, heating system, automatic ventilation system, additional lighting, pressure and wind speed sensors, steam generators, etc.).

Types of material

Polycarbonate. Relatively inexpensive coating for structures. Widely used material. Lightweight, durable (service life up to 35 years), durable, elastic. Not afraid of moisture, resistant to mechanical damage and large temperature fluctuations. It transmits sunlight well, while protecting plants from ultraviolet radiation. The cellular structure serves as a good heat insulator. The big minus is very high flammability.

Glass. It transmits light perfectly, is non-flammable, and does not emit harmful substances when heated. But at the same time, the material is quite heavy and fragile.

Polyethylene. The most budget option. UV unstable. Withstands no more than 1-2 seasons. It needs to be dismantled by winter. Condensation accumulates on the reinforced film inside the structure. Because of this, air circulation is disrupted.

Pros and cons of the design

The frame is a load-bearing structure, so you need to carefully weigh everything when choosing what it will be made of.

- A wooden base is the cheapest option and requires a minimum of tools and work skills. But it won’t last long, because wood rots and breaks down in high humidity. Since wooden beams do not bend, a round roof cannot be built from it. When covering with polycarbonate, cracks form in the corners that need to be sealed.

- PVC pipes bend easily, stick well, but crack at low temperatures. Such a frame does not withstand winds and is easily deformed.

- A frame made of a metal profile will be more expensive than the previous ones.

- Steel is stronger and more durable than all, but heavy.

- Aluminum durable, lightweight.

- And galvanized is lightweight, does not corrode, but does not withstand heavy loads. Requires great skills, tools and labor to manufacture. However, it is stronger, can withstand any temperature, and can be bent with the help of special equipment. Durable.

Business benefits

Is it even worth doing something like growing plants in industrial-scale greenhouses? Everyone decides for themselves. It is worth considering a number of advantages of this type of activity:

- No need for large start-up capital - unlike most enterprises, you do not have to purchase large quantities of raw materials, goods for resale, or set up production facilities - you just need to build a greenhouse and plant the land with seedlings;

- A wide variety of activities - from season to season you will have to change the types of crops grown, as well as monitor the demand for certain plants and adapt to market requirements, which will never let you get bored;

- You can create a business from scratch yourself, maybe even build an industrial greenhouse with your own hands; construction projects, videos of which are presented below, are other people’s experience and mistakes that will help you implement your ideas;

- Wide possibilities for automation of work, possible thanks to modern technological advances;

- Possibility of generating income throughout the year, for which artificial lighting and hydroponic technology can be used;

- Constant growth and increase in income;

- High profitability of products;

- No harm to the environment;

- The opportunity to realize oneself in different areas - if things go well, you can always expand and additionally engage in related agricultural activities in the countryside - for example, livestock farming or dairy production.