If you are writing a business plan, then you need to consider everything you need to start your own business. One of the profitable ideas today is powder coating of metal parts. Many people resort to the services of specialists in this direction. On the one hand, it seems that there is no easier way to earn money, but there are also many pitfalls in this matter.

Benefits of powder coating

Before building your business, you need to carefully calculate the risks. The advantages of powder pigment coloring technology include:

- cost-effectiveness (paint that gets past the part should be collected and reused);

- losses of consumables are 5%, and there is no need for a solvent;

- ease of use of paint (it is sold ready-made);

- high line speed (no need to dry the product);

- durability of the painted product;

- the finished coating has decorative properties;

- environmental friendliness (production is waste-free).

Advantages and disadvantages

Coating technology using powder paints has many advantages compared to painting with liquid materials: . Powder paints are supplied to the consumer in a ready-to-use form. No preparation, mixing, dilution, stirring, or viscosity adjustment is required; . the production of coatings, as a rule, is limited to a single-layer application, while liquid paints require the application of several layers, the coating production cycle is longer; . Paint recycling and almost complete return to the production cycle are easily ensured. This achieves higher production efficiency; . energy costs for the production of coatings are reduced due to the absence of solvents (no energy is required to evaporate solvents, ventilation costs are reduced); . the possibility of mechanization and full automation of the coating production process is provided, which allows reducing the number of personnel and saving production space; . Higher quality coatings and better performance properties are usually achieved.

Currently, in industry, from the point of view of technology, economics, and ecology, there is practically no alternative to powder paints and varnishes.

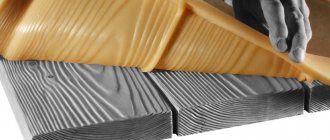

Pigment application technology

The peculiarity of the work is that powder painting is a dry method of applying pigment. The spray gun charges the powder particles so that they become magnetic. When sprayed, they simply stick to the grounded metal. It is important to apply the powder as evenly as possible.

The second stage of the work is melting. The part with the powder applied to it is placed in a special chamber where it is “baked.” The temperature in this oven reaches 250 degrees Celsius, after which the part needs to be cooled and can be transferred to the client. The work seems quite simple in appearance, and in fact it is. However, the effectiveness of your business depends on how you organize it.

Powder coating of wheels

Once all the conditions for independent restoration work have been met, you can proceed to direct processing of the disks, carried out in accordance with the requirements of current regulations.

Before you paint car rims with your own hands, you need to carefully familiarize yourself with the technological features of these procedures. According to accepted standards, the order of their implementation is as follows:

1. Before starting painting work, the surfaces of the disks are thoroughly cleaned of corrosion, old paint residues, as well as traces of dirt and oil stains using a metal brush, sandpaper and solvent (abrasive and chemical treatment, including degreasing).

If it is impossible to remove rust embedded in the metal, you will have to organize its etching, carried out using solutions of various acids (sulfuric, phosphoric, hydrochloric or nitric).

Please note: When performing these operations, special attention must be paid to observing safety precautions when handling chemicals.

2. At the next stage of surface preparation, it is treated with chromium, iron or manganese phosphate, which helps improve the adhesion of the metal to the protective primer. Upon completion of the phosphating process, the discs prepared for painting are thoroughly washed with warm water and then dried.

3. Next, they proceed to applying a special primer coating to the surface, which ensures improved anti-corrosion properties and adhesion to the sprayed dye. To protect cast wheels, epoxy (epoxy-zinc) primers are usually used.

4. Upon completion of the preparatory work, the discs are placed in a special painting area or box with limited scattering of microparticles sprayed by the gun (in this case, the body of the processed products is reliably grounded).

What is engine chip tuning, pros and cons. - there is more useful information here.

5. The powder mixture is applied to the surfaces to be treated using the electrostatic spraying method, according to which charged particles, when scattered, are attracted by a grounded metal disk.

Important! When spraying powder dye, the spray gun or gun should be located at a distance of approximately 30-50 cm from the surface to be treated.

Upon completion of paint application, the discs are subjected to special heat treatment (so-called “polymerization”), which ensures the melting of the protective layer and its reliable adhesion to the previously prepared coating.

You might be interested in this article - Do-it-yourself airbrush on a car.

For this purpose, they are either placed in a home-made oven or subjected to high-temperature treatment using powerful electric heaters.

What will you have to spend money on before starting a business?

First of all, let's talk about the premises. It should be spacious, dry, bright and clean. The last condition is extremely important, since the unused pigment will need to be collected. It will not be possible to use it a second time in a dusty room. In addition, it is imperative to arrange ventilation and grounding in the painting shop.

The equipment for painting should be as follows:

- powder application chamber;

- polymerization oven;

- a sprayer that imparts an electrostatic charge to the material;

- overhead conveyor;

- recuperator;

- compressor.

As an additional equipment, you must definitely buy a compressor. It must be powerful, as it will act as a source of compressed air. A recuperator is a special vacuum cleaner for collecting powder. At first, to save money, you can replace it with a Cyclone type vacuum cleaner.

A transport system with a hanging mechanism is necessary in order to paint large parts, such as car body parts. The parts will move along it from one painting area to another. You can make it yourself from a monorail and a movable carriage with a hanging mechanism, but later it is best to replace it with specialized equipment. Remember that customers will judge your business by its facilities. No one can contact a service center where work is carried out literally “on your knees.”

Powder application chamber

Let's consider the basic set of equipment. If you are going to use a conveyor, then you need to make two doors in this room. An important condition for the painting chamber is tightness. The passages should have a minimum of gaps - the better you seal all the joints, the easier it will be to remove the camera.

A prerequisite is a floor insulated with a rubber coating. The chamber itself can be built from corrugated sheets. It must have ventilation and good lighting. It is best to use energy-efficient LED lamps for lighting, as powder will settle and stick to other types of lighting fixtures.

Spray

The set of equipment for painting must include a spray gun. The work can be done safely and quickly using a tribostatic sprayer. It charges the powder with a small electrical charge, which appears during the friction of the parts of the spray gun. Advantages of this sprayer:

- the ability to process metal products of complex shapes;

- creation of high-quality coverage;

- uniform application of powder;

- durability of the equipment design.

This sprayer is easy to use by changing the can of powder, which is installed on its body. The part can be painted in several colors at once.

Wheel coloring technology

Coating the discs with powder paint gives a lasting effect of restoring the metal.

Powder painting is often called polymer painting because of an important stage of the technological process - polymerization, which is carried out on the basis of special equipment at high temperatures.

Unfortunately, the process itself is quite labor-intensive and requires certain conditions and equipment. Therefore, we will analyze each stage in detail in order to make an informed decision: to carry out the painting yourself or contact a car service.

Preparatory stage

To prepare for painting, the part should be thoroughly cleaned of old paint, rust and all kinds of contaminants. This is done by sandblasting the discs. The products are placed in a sandblasting machine, in which a stream of compressed air with sand or abrasive under pressure knocks off the old coating. Auto repair shops can also use acid and alkaline compounds.

sandblasting discs

If necessary, you can order phosphating of the metal to subsequently increase the adhesion of the paint to the surface of the wheel accessories. Phosphating creates an additional anti-corrosion layer of several microns. Sandblasting is followed by washing and drying.

Padding

Performed using epoxy powder primers. This procedure gives car/motorcycle wheels anti-corrosion protection and ensures better paint adhesion. A layer of powder primer is applied with a special pulse gun. Particles of such soil, under the influence of an electromagnetic pulse from the gun, settle on the disk (magnetize). When the application of primer is completed, the discs are placed in an oven at 200° for 10-15 minutes.

Wheel painting

This stage is carried out on the basis of special equipment for powder painting. Powder spraying takes place in a spray chamber operating on an electrostatic principle. Painting is carried out using a special gun.

Polymerization

The final stage procedure is carried out inside a polymerization oven, which has an electrical control unit, for 15-20 minutes. Temperature inside the chamber: 200-220°C. The powder composition of the paint melts in the oven, forming a uniform film over the entire structure.

In conclusion

After polymerization and drying, the parts are polished and, often, a finishing coating (varnish) is applied. After 3-4 hours, the discs can be placed on transport, but not used earlier than after 24 hours. If varnish was used, complete drying will occur in about a week.

Features and stages of polymer painting of wheels at home

To carry out painting of wheels yourself, you must have a special room for arranging a painting booth. If a garage is used, there should be enough space for painting and heat treating the wheels. For polymerization you will need a heating system or a thermal oven. In addition, the room should be well lit for visual inspection of surface painting.

Important: it is necessary to provide forced ventilation to ensure that microparticles of dye and dust hazardous to human health are removed from the working area.

The painting steps are the same as in car repair shops:

- Preparation: the discs are cleaned, degreased, and old paint is removed using an abrasive. That is, the car part is being prepared for paint application. Straightening and putty smooth out chips and scratches.

- Priming: here you need to choose a reliable material, because without a primer it will not adhere well.

- Painting: For self-painting, use polymer paint in a spray can. During the application process, you need to monitor the spray speed and the distance from the can to the metal. If you can rent or buy a special gun for powder painting and a compressor for it, the paint itself can be applied more professionally and evenly.

- Polymerization and drying: for these purposes, a high-power electric heater system is used at home. It is important to take care of the safety of electrical conductive networks so that there are no short circuits during operation.

- Polishing and applying a final protective coating (varnish)

The main advantage of painting wheels with polymer at home is the economic benefit compared to a car repair shop. But the process is labor-intensive and requires a lot of time in terms of preparation and creation of certain conditions. Therefore, it is much easier to contact a specialized service.

How to carry out polymerization

If this is the only time you are painting, you can fix the coating in the oven, but it is not suitable for making a profit from providing painting services. It is best not to skimp on the polymerization chamber and purchase a new model equipped with infrared heaters. Advantages of modern polymerization chambers:

- you can paint with several shades of pigment at once;

- low amount of electricity consumption;

- the temperature can be adjusted accurately, and the sensors are very sensitive;

- the operation of the emitters can be adjusted manually;

- there is ventilation, which helps not to spoil the finished product and at the same time reduce the harm from the process to others;

- you can control it autonomously or in a combined way;

- wide range of operating temperatures.

Dye selection

In this section, we move on to describe the most critical part of the preparatory activities, which is choosing the appropriate powder coating. In it we will try to answer the following questions that interest every car enthusiast:

- How to paint car rims yourself (i.e., with your own hands)?

- What are the features of choosing a powder dye suitable for these products?

When studying these issues, first of all, let us draw your attention to the fact that the domestic market offers a large number of types, brands and colors of dyes of this class. That’s why, before you paint your car’s rims yourself, you need to decide on the choice of powder material suitable for your conditions.

It should be assumed that the following types of polymer coatings can be used to paint discs with your own hands:

- epoxy paints;

- polyester and polyurethane compounds;

- silicone dyes.

Each of the powder coating materials listed above has special, inherent qualities that determine the degree of security of the processed product. Thus, epoxy compositions are characterized by increased resistance to alkaline and acidic environments, and polyester paints have excellent anti-corrosion properties.

The advantages of polyurethane coatings include increased resistance to solvents and abrasives.

Silicone dyes differ from others in that they can withstand significant temperatures.

Important! You can choose a specific type of dye only after familiarizing yourself with the features of each sample, which determine the possibility of using it for self-application at home.

The most common and well-known names of powder protective coatings include such well-known domestic and foreign samples as “Pulverit”, P-EP 45, “Infralit”, “Bichon”, “Beckers”, “Radar”, “Inver”, TFC and Flycoat.

Using products from these manufacturers, every car enthusiast can easily cope with all the tasks assigned to him, including selecting the appropriate color scheme (in the RAL standard) and the surface texture of the wheels.

Using some of these dyes, you can change the structure of the coating, which is represented by a number of popular types (shagreen, antique, moire and the like).

Additional information: powder coating of wheels requires the mandatory use of special work clothing and respiratory protection.

As such, in domestic conditions, a regular respirator, safety glasses and thick cotton gloves are most often used.