Business relevance

Opening a temporary storage warehouse as a business is an interesting and promising idea in the B2B services sector. Many companies forced to store large quantities of raw materials or finished products are looking for ways to optimize this stage of work. Maintaining your own warehouse is expensive: rent, utilities, equipment and staff labor. A profitable solution is to use the services of specialists and replace all expenses by paying for the rent of a ready-made warehouse space.

The tendency to reduce your own costs and outsource as much work as possible makes opening a warehouse for tenants a relevant and modern business. With a good level of organization, it will be possible to find regular customers who will bring a stable income to the entrepreneur. Another advantage is that such a business is just beginning to develop; in many regions the industry is absolutely free. It will be easy for a start-up company to enter the market due to low competition.

But the warehouse services business is not without its drawbacks. Building your own premises from scratch is expensive, so the payback will take several years. Renting is fraught with the risk of losing all invested funds and client base at any time (if the tenant decides to terminate the contract and take the business for himself). But even the high cost of construction and risks cannot cover the prospects that a temporary storage warehouse opens up.

Many companies prefer to rent space in someone else's warehouse rather than build their own

Market analysis

First of all, you should determine some points:

- it is necessary to determine the characteristics of the product for which the warehouse will be built;

- analyze the need for warehouses among distributors specifically for this product;

- decide on the type of warehouse (seasonal, reserve, production, wholesale, retail or general use);

- compile lists of potential tenants, buyers and partners.

for 550 rubles, from our partners, with a quality guarantee.

Types of warehouses

To prepare a business plan for a warehouse complex, first determine its type. The choice is based not only on the wishes of the entrepreneur, but also on a preliminary study of demand. It is important to understand what kind of warehouse is required in the region. There are several classifications.

By purpose of use:

- Production. Raw materials and finished products are stored here. Such warehouses are most often built on or near enterprises to simplify logistics.

- Transit. They are located at transport interchanges, railway junctions, and near airports. Cargo is stored here for a short period of time, between loading onto other vehicles.

- Distribution and wholesale. Large quantities of goods are stored and distributed in several directions, for example, to several retail outlets.

- Customs. Designed for storing goods during clearance of transportation across the border. You can only open a customs warehouse directly near the border with another state.

- Retail. Used to store products from one retail outlet.

- Reserve. Designed to store stocks of raw materials and finished products until required.

- Responsible storage warehouse. A special variety that is not suitable for business. This designates the place of storage of goods that the buyer refuses for any reason. The cargo is stored there until the end of the proceedings.

By design:

- Closed. Traditional, fully enclosed hangars.

- Semi-closed. Premises protected by only 2 or 3 walls.

- Open. Areas adapted for storage, covered with an awning. The most unsafe.

By product type:

- Specialized. Designed to store only 1 type of product or raw material. For example, dairy products, meat, fish, shoes or clothing.

- Mixed. Products of related categories are stored here. For example, grocery, clothing, raw materials.

- Universal. Adapted for storing different types of products and raw materials.

The optimal solution for business would be a universal closed warehouse of production, transit or reserve type. A customs warehouse is also profitable, but it can only be opened at the border, which significantly reduces the number of potential entrepreneurs.

Warehouses are classified depending on their purpose, design and level of equipment

Western classification

In Western countries, it is customary to divide warehouses into classes from A to D, depending on area, purpose and other requirements. In Russia, such a classification is not established by law. But in practice, the letter description of warehouses is used quite widely:

- A+. This is the highest category, which includes rectangular one-story hangars made of especially strong light metals. Their height allows you to store products in 6-7 tiers. Equipped with ventilation, temperature control system, security system, video surveillance and fire extinguishing. The territory may have conference rooms, food outlets and other additional facilities that increase the comfort of users.

- A. The requirements for category are almost the same as A+, but differ in lower ceiling heights (at least 9 meters) and building materials (not only metal structures are allowed, but also sandwich panels.

- B. They are considered the best option in terms of price and quality of storage. Multi-storey buildings with ceilings from 4 to 8 meters. It is permissible to organize such a warehouse in a converted, rather than specially built, premises. Concrete and asphalt floors are allowed, heating and alarm are provided.

- C. Insulated hangars with ceilings from 4 meters. Any number of floors is allowed. At the zero level there should be a gate for the loader to enter inside. There must be an alarm system, a fire extinguishing system, and access control. Most warehouses in Russia belong to category C.

- D. Basements, hangars, basements and other industrial premises used for storage. Minimum requirements that differ in each individual case. They often work without heating, limited to a fire extinguishing system. Their only advantage is the low rental cost.

Download the wholesale warehouse business plan template and you will be able to:

- Without wasting extra time searching for consultants and avoiding the need to pay for their services, independently calculate the main indicators of project effectiveness.

- Prepare for meetings with potential investors and lenders and disarm them with a professional business plan with accurate and detailed calculations.

- Use the received document not only at the development stage of the project, but also at the stage of the current operation of the warehouse when drawing up financial plans and budgeting.

- Avoid mistakes at each stage of the project and control the degree of completion of each step of the work.

Owning a warehouse is an excellent option for a profitable and stable business. If you decide to engage in this type of activity, be sure to use a business plan template. Start acting right now, and the results won’t take long to arrive.

Other ready-made business plans:

- Logistics center business plan

- Business plan for building a house

- Business plan for the construction of a residential building

- Business plan for the construction of wooden houses

- Business plan for a residential complex

- Village business plan

- Business plan for a cottage village

Registration of documents and permits

To attract regular customers to your warehouse, you need to officially register your business. Individual entrepreneurs and LLCs are equally suitable for this work; the choice remains with the warehouse owner. Registration is required not only for paying taxes: potential clients are ready to trust their property exclusively to reliable partners, preferably legal entities. The work will be carried out under a contract.

In addition to the registration certificate, you will have to obtain other permits. Their specifics depend on the type of warehouse and what products are planned to be stored. For example, a food warehouse must be inspected by Rospotrebnadzor and SES, which will confirm compliance with storage conditions. Any of the warehouses will have to undergo an inspection by the Ministry of Emergency Situations or the fire inspection, without a positive conclusion from which cargo will not be stored.

Drawing of a one-story hangar-type warehouse

Summary

The purpose of this business plan is to create a one-story warehouse with an area of 30,000 square meters, the internal height of which is 15 meters. It is also planned to create an administrative and amenity block of five floors with an area of 600 square meters and a block for a technical room. The warehouse will be divided into three main areas:

- 10,000 m² – for alcoholic products

- 10,000 m² – for industrial goods

- 8000 m² - divided into two chambers, one for the storage of vegetables and fruits, the temperature range of which is from 0 to +8, the second - with a temperature no higher than +2, for the storage of meat, sausages and fish products.

- 2000 m² – storage room for frozen foods.

The warehouse space will be occupied in such a way as to maximize the usefulness of its space (shelves, stacks).

Creating your own class B warehouse complex, which differs from higher categories only in area and ceiling height, is very important in our time, since the storage system is just being established and old-type warehouses no longer meet the requirements and operational standards. Refrigerated chambers for storing gastronomic products, vegetables and fruits are in great demand. The lack of cold storage can lead to food shortages in communities and regions.

What is more profitable to build or rent premises?

An entrepreneur who decides to open a warehouse inevitably faces the question: should he build a hangar himself, or should he buy or rent suitable premises? Each option has pros and cons, and the choice must be based on the financial capabilities of the entrepreneur and the characteristics of the region.

Construction of a warehouse will add about 1 million rubles to the starting investment, but will allow you to implement your own plan for the warehouse premises, select the required height and materials.

If you build a warehouse yourself, starting a business will take at least 3 months. The layout drawing is presented in the images accompanying the article.

Renting is attractive because it significantly reduces the start-up capital. Funds will be required only for repairs and re-equipment. This option is much faster than construction - you can receive clients within a month. There is only one minus, but a very significant one. An entrepreneur takes a risk by investing in someone else’s premises and building a client base. There is a threat that the owner will decide to take over the business and simply not renew the lease. It will be difficult to challenge such a decision in court.

Buying premises is the third option for opening a warehouse - safer than renting and less expensive than building it yourself. Old warehouses, workshops, hangars, industrial buildings in areas of transport interchanges and other places with good transport accessibility are suitable. For them, you need to prepare a modernization and repair plan. The layout of the warehouse area should be prepared by specialists who will develop the most convenient plan for transporting and storing goods. If you can find a suitable hangar that can be adapted for storage, this method of opening can be considered the most profitable.

Storage equipment

A business plan for a wholesale warehouse should include the purchase of special equipment and machinery that will help store, unload and package cargo safely and at high speed:

- racks;

- storage boxes;

- scales;

- stairs;

- hydraulic lifters (fork trolleys);

- standard trolleys;

- slings;

- hoists (suspended lifting devices);

- pallets and trays;

- loaders.

The cost of equipment depends on the warehouse area. It is more convenient to buy everything you need in bulk or online. By studying the range online, you will be able to compare prices and find the best solutions.

Forklifts or forklifts are a must-have equipment for any warehouse

Recruitment

The bulk of the warehouse staff consists of storekeepers and loaders. These are specialists who will unload and load products, keep records of them, plan storage, and transport them. Experience in a similar field is desirable, but any candidates with secondary specialized education are suitable. This category of workers is led by a foreman (a different job title is possible). He draws up a sample monthly warehouse work plan, employee schedule and other current documents.

If the warehouse is large, you will need a logistician - an employee who will plan the placement of goods. The loaders are operated by drivers who have undergone training (not in production, but with a certificate confirming their qualifications).

Finding employees for the warehouse will not be a problem. You can use street and newspaper advertisements, as well as websites with vacancies on the Internet. When searching, take into account not only professional skills, but also equally important personal qualities - accuracy, attentiveness, absence of bad habits, punctuality.

Necessary design documentation

The amount of investment will depend on the area, equipment and automation of the warehouse

Both urban planning and architectural documentation must reflect economic objectives:

- Transport accessibility is important; it is also necessary to provide the required number of parking spaces and identify highways along which the main cargo flows with which transport connections need to be established will pass;

- Required equipment - competent planning and modern equipment and equipment will ensure a high price for the facility;

- Warehouse parameters: area and number of separate premises;

- Ancillary facilities and premises: the warehouse will not function without additional places for loading and unloading, checkpoints;

- The required warehouse size must be determined by analyzing the goods that will be present in the warehouse;

- Determine the necessary materials for construction - a properly drawn up business plan will help you build a building from inexpensive structures and materials;

- Workers – a large number of builders will allow you to quickly build a warehouse at a reasonable cost.

Advertising services

This category of services belongs to the B2B sphere, that is, “business to business”. The warehouse's clients will be entrepreneurs, small and medium-sized companies. Their goal is to save money on building their own warehouse, store raw materials and resources in reliable conditions. The warehouse owner should take these factors into account when planning advertising.

The best source of regular users will be sending commercial offers. Prepare a database of potential clients and send them an email presenting your business:

- warehouse address;

- interior photographs;

- list of equipment useful to the client (loaders, conveyors);

- conditions and cost of cooperation.

Outdoor advertising will be no less useful - billboards, posters, banners, posters and light boxes. Thousands of people pay attention to them every day, and there will definitely be potential clients among them. There is only one drawback - high cost. The same can be said about advertising on TV and radio. It brings many clients, but is expensive for the entrepreneur.

A good option, optimal in terms of efficiency and cost, is to promote through social networks. Most companies maintain business accounts there and look for clients and partners through them. You can register an account completely free of charge, and promote it for free or with a small investment. Subscribe to all potential clients on Instagram and VKontakte, send them messages with commercial offers, not forgetting to publish up-to-date information about your services and promotions.

Even with a small budget, a warehouse development plan should include advertising and promotion. Without this line of work, it is impossible to find a sufficient number of clients, which means it is impossible to start earning money.

Customers will be attracted by an equipped and well-protected warehouse

Conducting an advertising campaign is important for running this business. Having your own website on the Internet, where all the information about the company will be located: contact details, list and photographs of the company’s personnel, etc., will help familiarize potential clients with the company’s activities. On the site you can post photographs, sketches and designs of warehouses that have been built or may be built in the future.

In addition to advertising information, you can publish various articles about the construction of warehouses, as well as about storing materials in a warehouse. Information must be constantly updated and supplemented.

An advertising campaign must be actively carried out on television, radio, in magazines and newspapers, which will help attract new customers and investors to this business.

Payback of a warehouse complex

How quickly an investment in a warehouse will pay off primarily depends on the initial investment. A self-built hangar will most likely pay for itself in several years, because the investment in it will exceed 1 million rubles. When purchasing or renting premises, you can count on net profit within 1 year of operation.

The location decides a lot: the better the warehouse is located, the more it will earn.

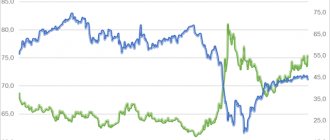

But it is not always clear to a novice entrepreneur what amounts and income are involved in this business. The warehouse makes money by renting out space, which is measured in square meters, cubic meters or pallet spaces. On average, renting a pallet space costs from 4 rubles per day and from 120 rubles per month. This is the minimum cost, you can safely increase it by 2 times.

Let’s assume that a warehouse has 1000 pallet spaces at an average price of 150 rubles per month. When fully loaded, it will earn 150 thousand rubles. The downside is that places are almost never 100% occupied. A good level would be 70–80% load, that is, 105–120 thousand rubles. In such conditions, you will be able to earn more than 1 million rubles in a year.

Volume plan for the provision of services for the billing period

| Period | Name of service type | Volume of production and sales per month (m) | Price | Sales revenue (RUB) |

| 1-12 month of investment | Sale of warehouse premises | From 300 sq. m | from RUB 33,963 sq.m. m | From 5,054,000 rub. |

| 1-12 month of investment | Renting out warehouse space | From 3,000 sq. m | From RUB 3,396/sq. m | From 5094432 rub. |

| 13-24 month of operation | Sale of warehouse premises | From 360 sq. m | From 38,000 rub. sq. m | From 13140400 rub. |

| 13-24 month of operation | Renting out warehouse space | From 3,600 sq. m | From RUB 3,800 sq.m. | From 13696340 rub. |

Organization and improvement of warehouse operations

Organization of a warehouse and warehouse accounting includes work on the warehouse processes themselves, and also requires automation of routine processes. Let's try to figure out how to organize the work of a warehouse, automate processes, improve performance and get acquainted with some recommendations. Keep this list for yourself and note what work you have already completed and what remains to be done.

Expert Alexey Snegur talks about the most common problems in organizing a warehouse and solving critical situations in a warehouse.

Unloading and receiving

- Use regulations for orderly unloading, taking into account the specifics of goods, quantity, the need for packaging and dispatch time.

- Conduct unloading, simultaneously recording and controlling quantity/quality.

- Avoid mis-grading; labels should be easy to read.

- On the day of arrival, unload and take into storage.

- The quantity must correspond to that indicated on the invoice.

- Increasing the speed of unloading and registration is possible by assigning certain categories to suppliers: “most reliable”, “reliable”, “needs to be checked”, etc. - this way you can save time on checking the goods.

- Draw up an act in case of shortages, surpluses, mismatches.

Placement of goods after receipt must take into account weight and dimensional characteristics

Storage

- Allocation of specific zones for categories.

- Organize storage areas for SKUs within designated areas.

- The most popular goods should be in an area of easy access and located as close as possible to the shipping area. Demand can be determined using ABC analysis or by the number of requests.

- Store large items near the shipping area and valuable items in the back of the warehouse.

- Allocate space for goods for static storage; for dynamic storage, use free space at the time of receipt.

- Do not store the goods on the floor, inspect the integrity.

Correct placement of goods in the appropriate storage areas is the key to their availability when collecting orders.

Picking and shipment

- The cargo must be accompanied by accompanying documents.

- Process applications received before 12:00 on the same day.

- Ship according to priority.

- Combine several ways to complete your order.

- The vehicle's carrying capacity and axle load must match.

- Do not place a heavy product on top of a light one. If the item is damaged during shipment, please replace it immediately.

The speed and accuracy of selection and shipment of orders depends on the correctness of their placement in accordance with the chosen scheme (for example, address storage)

Warehouse zoning

- Divide the warehouse area into zones based on cargo turnover and inventory turnover.

- Use each warehouse area to its maximum benefit, rent out unused spaces.

- Create a “reject” area for products that do not meet established requirements.

- Ensure that aisles and passages inside the warehouse are wide enough.

Dividing the warehouse into zones allows you to assign responsibility for better control over the assortment of each zone