Types of profitable production

Before you start implementing new small business production ideas, you need to conduct a thorough marketing analysis and calculate future expenses. After this, you need to develop a competent business plan. Thanks to this, you will be able to clearly structure all stages of business development. This is especially true for those beginning entrepreneurs who are going to take out a loan to start a business.

In addition, you need to analyze the market to identify products that are in great demand among consumers. It should also be remembered that almost all enterprises undergo certification and receive permits to conduct activities from various authorities. Try to choose a production area for a small business that does not have very strict requirements, otherwise you will have to pay a decent amount for obtaining permits.

Let's try to figure out what is the most profitable production for small businesses.

Experts highlight the following areas of activity:

- Food;

- Household chemicals and hygiene products;

- Construction Materials;

- Hosiery;

- Simple metalworking.

Now let’s look at several ideas for mini production for small businesses from these areas, which are characterized by quick payback and high profits.

Types of factories for small businesses

Entrepreneurs should pay attention to the so-called modular mini-factories. Their advantage is that the owner is not tied to the rented space. An example is the production of gas silicate blocks. Such mini-factories are offered not only in China, but also made in Turkey. The price, depending on performance and configuration, varies from 50 – 400 thousand US dollars. The plant can be easily dismantled and transported to another location. Such a mini-plant can be easily expanded by adding additional modules, starting from the smallest one.

In food production, the most in demand are mini-factories and lines for the production of bakery products, sausages, and bottling of mineral and drinking water. The latter is the most profitable today. The demand for drinking water is only growing.

clothing industry

One of the most promising small business ideas at home is the production of garments.

We are talking about a universal studio that can satisfy any consumer needs, from sewing children's clothing to bed linen or curtains. Sewing products are in demand in any, even the most difficult times, since they are bought by all citizens of our country, without exception. If you provide a competent approach, your business will flourish and bring you a stable income. Let's figure out where to start sewing production? This is not an easy task. Organizing the smallest studio will require experience and certain knowledge from you. There is a high level of competition in this segment, so first of all you need to conduct a thorough market analysis and develop a competent strategy. In addition, you will need money to purchase sewing equipment and train staff. It is not so easy to name the exact payback period for a universal sewing production, so experts recommend that beginners start with a narrow specialization, for example, sewing jackets or suits. Another profitable option is the production of things that are often found in everyday life - bed linen, towels, tablecloths, etc.

According to experts, a sewing workshop is the most profitable production for small businesses, which opens up broad prospects for businessmen and promises them decent profits. It will be difficult at first. But if you work with large volumes of products, after 1-1.5 years the business will pay for itself and reach net income.

Metallurgical mini-plants

| 1.1 The role and place of metallurgical mini-plants in the overall structure of ferrous metallurgy |

In recent years, the global metallurgy industry has seen an intensification of competition with a simultaneous decline in the growth rate of metal consumption; there is a gradual replacement of the strategy of concentrating steel production at an integrated enterprise in favor of the creation of compact and flexible technological modules. This situation significantly stimulates intensive structural restructuring of the industry both within the regions and at metallurgical enterprises. This circumstance partly explains the fact that the current stage of development of the global iron and steel industry is characterized, in most cases, by low profitability due to slowing growth, increasing competition, and excess production capacity (Fig. 1.1). World steel production in 2003 reached 945.14 million tons with a capacity of 1070 million tons. Thus, the excess capacity in world production in 2003 amounted to about 124.86 million tons. In recent years (1990 - 2003), world steel production increased by 174.6 million tons, and world capacity increased by 130 million tons, i.e. there is an accelerated growth of capacity compared to production [1, 2, 3]. Thus, if over the given period the global steel production capacity increased by approximately 22.7%, then its utilization rate ranges from 75.0% to 82.4% (Table 1.1).

Fig.1.1

. Dynamics of global steel production, million tons

The main increase in production capacity occurs in China (250%) and the Republic of Korea (150%), a slight increase is also observed in countries with developed metallurgy (7%). Such growth rates are associated with significant investment in ferrous metallurgy. The rest of the world is experiencing a decline in production capacity [4].

Excess production capacity has a negative impact on market conditions. Note that ten countries: China, Japan, USA, Russia, Germany, Republic of Korea, Ukraine, Brazil, India and Italy account for 75% of global steel production. In table 1.2 shows the dynamics of steel production in the world and in the top ten countries.

Table 1.1

. Global production capacity utilization rates, %

Let us note that every year the role and importance of large steel producers is growing. Thus, the share of their production increased from 69.54% in 1993 to 78.86% in 2003. At the same time, the main place in world production is occupied by China, where steel consumption is gaining enormous momentum due to the massive transfer of production capacity to the country Western companies and the implementation of a large number of infrastructure projects [5].

Table 1.2

. World steel production, million tons

In addition, the development of global metallurgy is accompanied by the following phenomena:

- The level of costs in the production and sale of metallurgical products becomes the determining factor that allows us to take a competitive position in the market. The best sellers are factories located in areas with cheap energy, labor and raw materials.

- Intensifying international competition. In order to protect national producers from dumping producers in the CIS countries, states introduce high duties.

- The cyclical nature of production, which leads to a fall in industry profits.

- Development of processes of mergers and acquisitions of companies.

Features of the ferrous metallurgy of Ukraine are high capital, material, and energy intensity of production. The metallurgical industry largely determines the level of capacity utilization of a number of basic sectors of the economy. Thus, the production of metallurgical complex products consumes 14% of fuel, 33% of electricity from their total consumption in industry, 40% of raw materials and mineral resources from their total consumption in the CIS countries. Metallurgical enterprises provide about 30% of railway freight turnover.

Along with general global trends in industry development, Ukrainian manufacturers were significantly influenced by internal processes occurring in the country. During the Soviet era, the maximum steel production in Ukraine was reached in 1988 (55.7 million tons), while Ukraine was not integrated into the world market, therefore, there is no point in mechanically comparing the productivity of those years. However, it should be noted that the specific volume of steel production for a state of the size of Ukraine was excessively high and amounted to more than one ton per capita. In 1991 - 1993 after a sharp decline in the production of ferrous metals in Ukraine, a period of relative stabilization began (Fig. 1.2) and in 2003, Ukraine ranked seventh in the world in terms of steel production. At the same time, despite the fact that the sharp decline has stopped, the general economic indicators of enterprises in this sector continue to remain low. This is primarily due to the characteristics of the domestic metallurgical industry, namely:

- I.

_ General economic crisis in the country. Metallurgy, as one of the main industries in Ukraine, could not help but experience the consequences of crisis phenomena: a decline in production, a decrease in profitability and product quality, an increase in material and energy intensity, social problems, strikes, and general non-payments. - II

. Lack of strict government management of the industry. To replace the destroyed management scheme for the metallurgical complex of the “Soviet period” with a vertical chain of command and responsibility for the conditions of the emerging market, a new one is gradually being created [6]. Added to this were the problems associated with the beginning of corporatization and privatization of metallurgical enterprises. Managers of mills and factories have to learn to work with new owners or investors, which in many cases leads to conflict situations. - III

. Lack of financial resources, which led to difficulties in paying for raw materials and electricity, equipment and repair work, shipped products, “barterization”. Payment discipline deteriorated significantly: almost all enterprises had significant amounts of both accounts payable and receivable. Mutual offsets and barter have become perhaps the main form of payment. In this situation, pricing for raw materials, energy resources and finished products was carried out taking into account barter, that is, at an inflated level [7]. - IV

. Violation of normal relationships between enterprises of the mining and metallurgical complex. All enterprises in the industry - producers of raw materials for metallurgists, metallurgy itself and consumers of its products, which previously formed a single production chain, have largely lost the close cooperative ties that have developed over decades. Mining, coke, refractory, ferroalloy, metallurgical, pipe and machine-building enterprises began to function as disparate and isolated parts of a once single mechanism. Moreover, intra-industry conflicts have become frequent, having not only economic, but also “political” background [8]. - V.

_ Continued aging - physical and moral - of production facilities. The aging of fixed production assets by January 1, 1998 exceeded 85%. According to technical standards, by this time 89% of blast furnaces, 87% of open-hearth furnaces, 26% of converters, and 90% of rolling mills should have been decommissioned. Significant depreciation of fixed assets is aggravated by the lack of most enterprises of sufficient funds for reproduction purposes. The possibility of modernizing production capacities in metallurgy is very limited. Once constructed, they are usually used continuously until they are completely replaced. The age of fixed assets in Ukraine reaches 60–70 years, with a standard period of 25 years [9]. - VI

. Excessive production capacity in the industry for almost all major groups of metal products. The negative impact of this factor is aggravated by the high level of fixed costs. The capacities of the national metallurgy are designed to produce 45 million tons of steel, but they are loaded at 69.5%. Manufacturers are seeking to increase production capacity utilization in order to intensify and reduce costs through economies of scale, which reduce specific fixed costs per unit of production. - VII

. High energy intensity of Ukrainian metallurgical production. Energy consumption per 1 ton of steel is 1.5 - 1.8 times higher than in the USA. This is due to the use of outdated equipment and technologies [65]. - VIII

. Export orientation. It is known that enterprises of the metallurgical complex form the export-import potential of Ukraine [10]. For the vast majority of countries, the main sales of products occur on the domestic market. In the world, the ratio between domestic and foreign sales, varying by region, averages 80% and 20%, respectively. In Ukraine, the situation in this ratio is the opposite, namely: about 75% of rolled products are exported and only 25% are consumed domestically [11]. This situation is associated with a very low level of domestic steel consumption, which, according to the ENII of the Ministry of Economy, during 1990 - 2002. fell almost 5.5 - 6 times [12]. Thus, for nine months of 2004, steel exports from Ukraine amounted to 19.5 million tons with consumption of 5.3 million tons on the domestic market [366].

Fig.1.2

. Dynamics of steel production in Ukraine for the period 1990 - 2003, million tons

However, it should be noted that today the situation in Ukrainian metallurgy is improving. Thus, the share of barter has decreased significantly, production volumes have stabilized; restructuring was completed at CJSC MMZ Isteel (Ukraine), partially carried out at OJSC Enakievo Metallurgical, Nizhnedneprovsky Pipe Plant, and in the steelmaking shop of NKMZ; investments are being made in the reconstruction of individual workshops of the metallurgical plants of JSC Azovstal, Krivorozhstal, etc.

There is no doubt that the Ukrainian metallurgy at this stage of development demonstrates a development path that is associated with attracting limited investments for the organization of compact production. The general scheme of such enterprises is aimed at ensuring minimal production costs with maximum productivity, product sales and profitability.

Over the past 10-15 years, thanks to progress in the technology of electric steelmaking, out-of-furnace processing and casting of steel, the creation of curved continuous casting machines and high-speed section mills, the formation of excess scrap, the rise in cost of fuel, and, consequently, transportation, the economic concept of the so-called “mini” has been fully formed. -plants,” that is, plants with relatively low productivity (0.04-2.0 million tons of steel per year).

Since the 70s, in developed capitalist countries, a restructuring of the structure of the ferrous metallurgy has gradually been carried out, during which the role of large metallurgical plants has decreased. The growth in production at mini-factories using scrap metal and its substitutes as raw materials is due to the fact that they are commercializing scrap processing, which has significantly changed the competitive situation in the industry. It should be noted that by the beginning of the third millennium, a huge metal stock had been accumulated in the world - about 30 billion tons of steel, which requires constant improvement of technological options for scrap recycling [13].

An increasingly large share of products is produced in modern mini-factories, and if in the recent past they were focused on the production of mass-produced products, since the main emphasis was on reducing costs, in recent years the range of high-quality steel grades has been expanding. In 1999, production at mini-factories in the United States amounted to 46.2%, and in developed countries as a whole - 41%. Currently, 18 orders have been received in Russia for the creation of mini-plants, including the Norilsk Mining and Metallurgical Combine, the Murmansk Marine Plant, the Usolmash Production Association, the Turbine Blade Plant (St. Petersburg), Urengoy, the Tyumen Region, etc.

The modern content of the concept of “ mini-mill ” includes: relatively low production costs, minimal emissions of process waste into the environment, minimal downtime of equipment and units, minimal production cycle time with maximum productivity, sales and profitability.

In our opinion, all modern electric furnace melting shops of small capacity from 40 to 2000 thousand tons/year can be classified as mini-plants. This is due to the technology of incomplete cycle, since electric furnace melting shops of higher capacity are not economically feasible due to the need to stock a large amount of scrap metal and the presence of a corresponding demand for the assortment offered by the mini-plant.

In terms of design, a characteristic feature of the modern concept of a metallurgical mini-plant is a wide range of new technological processes and units, first mastered and adapted directly for this type of enterprise, and a high degree of their functional compatibility with each other in a single technological cycle.

Mini-plants include (Fig. 1.3): equipment for preparing scrap steel for smelting, an electric arc furnace, a steel finishing section (in particular, units for heating, averaging, degassing and desulfurization), a continuous casting machine, a rolling mill (with some components may be absent) [14, 15, 16]. This implies the presence of auxiliary production and services, as well as the necessary infrastructure. Thus, some of the energy-intensive processing processes available at integrated full-cycle plants are absent at metallurgical mini-plants.

Today in the world there are over a thousand mini-plants of various capacities and levels of technology (Table 1.3), which produce about 15% of global steel production. They are developing quite quickly and successfully in the USA, Brazil, India, Spain, Australia, Mexico, Germany, China, Taiwan, as well as the CIS countries [17].

Rice. 1.3

. Scheme of a modern metallurgical mini-plant for the production of long products

In Fig. 1.4 shows diagrams of the capacity and number of metallurgical mini-plants in the world. The most widespread are mini-plants with a capacity of up to 400 thousand tons/year; then, as productivity increases, the number of mini-plants decreases.

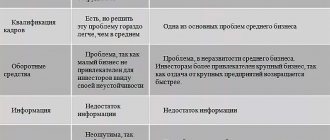

As noted above, mini-mills exist on the global and domestic markets on a par with large metallurgical plants. At the same time, the competitiveness of mini-plants and metal products is achieved due to a number of factors (Table 1.4).

Table 1.3

. Distribution of mini-factories in the world

Rice. 1.4

. Capacity and number of mini-plants in the world: 1 - capacity of mini-plants depending on ranges, thousand tons; 2 – number of mini-factories of corresponding capacity, pcs.

1

. The small capacity of the plant allows it to produce products directly for small orders. The production of rolled products in small batches depending on the needs of consumers within the region, as well as on the foreign market, allows for flexibility in determining the range of products and provides the ability to quickly respond to market requirements. Today, a number of world markets require supplies of high quality metal, at low prices, in small quantities and in a short time. A metallurgical plant with a full cycle annual productivity of 4-5 million tons and above can hardly fulfill such requirements, since not fully loaded capacities lead to higher prices for products, and an excess of produced products leads to difficulties in selling them. Under these conditions, the smaller the batch, the higher the payment for 1 ton of product.

Table 1.4

. Comparative technical and economic indicators of the operation of metallurgical mini-plants and full-cycle plants

*

When using primary raw materials of own production in the charge of electric furnaces, specific capital investments at mini-plants increase to 550 c.u./t.

**

Abroad, the number of industrial production personnel includes only workers directly employed in the main production

2

. Small areas required for equipment placement (18 - 20 hectares per 1 million tons of steel produced per year), the value of which is approximately 8 - 15 times lower than for traditional metallurgical plants. The construction of a mini-factory does not imply the presence of an extensive public infrastructure. Thus, the share of general plant facilities in the total volume of capital investments can be reduced from 60% (according to normative and actual data) to 20%, which is confirmed by the experience of creating mini-factories abroad, where the necessary services are performed by specialized third-party organizations. The greatest effect from construction can be achieved when placing equipment on existing areas, unfinished or freed up as a result of repurposing production [18].

3

. Relatively low cost of building a mini-plant. Specific capital investments per 1 ton of finished product according to various sources are usually estimated at US$150-300 compared to US$650-1000 for a full-cycle plant.

4

. Reduced energy intensity of production, which compares favorably with the high total energy intensity of equipment at large metallurgical plants [19].

5

. Full-cycle ferrous metallurgy is one of the mature industries with low investment attractiveness and is characterized by great inertia (the “construction – development – production” cycle often exceeds a ten-year period). For strategic investors, this industry is not a priority object for investing resources, since capital investments are deadened for a long time. The relatively short duration of design and construction of a mini-plant allows capital investments to be targeted at a minimum payback period. Thus, the construction of a mini-factory and the development of production capacities lasts only 1.5-2 years, so they begin to make a profit when the construction of an integrated plant begins to unfold [20].

6

. High potential for the reconstruction of traditional electric steel-smelting shops as part of the implementation of the compact mini-plant concept (the costs of modernizing an existing full-cycle plant are estimated at 100-200 US dollars per 1 ton of annual production, and only 50 for a plant with electric arc furnaces). In the new conditions, almost all enterprises initially refuse to build steelmaking shops on a free site and prefer to make maximum use of decommissioned existing buildings and equipment, i.e. The question is raised about minimizing capital, energy and material costs.

7

. Significant reduction in labor costs compared to full-cycle plants. Thus, in the production of long products, costs are reduced by approximately 2.5 - 3 times, and in the production of rolled sheets - by 5 - 6 times [21].

8

. Eliminating the transportation of raw materials over long distances through the use of scrap metal from a given economic region and consuming a significant portion of rolled products (or billets) directly in the area of their production can significantly reduce the share of transportation costs in the structure of product costs [22]. Thus, in the USA, the distance from a mini-factory to the consumer of its products, which are often delivered by the manufacturer’s vehicles, usually does not exceed 400 km. Such mini-factories focus on the production of rolled products that nearby regions need. These are most often reinforced concrete reinforcement, wire rod, and small shaped profiles.

9

. Attracting full-time personnel only in the main production.

10

. The use of scrap metal as a metal part of the charge allows iron to be reused. As is known, only arc furnaces are capable of efficiently processing scrap metal of a fairly wide range of quality.

11

. Achieving the minimum duration of the “smelting - casting - rolling” cycle. So at factories the average duration is 5 - 10 days, at mini-factories it reaches 10 - 16 hours, and at some 2.5 - 3.2 hours.

12

. The ability to coordinate the operation of the main technological units “electric arc furnace” - “after-furnace processing unit” - “continuous casting machine” in a fairly wide range of annual capacity (0.04 - 1.5 million tons of finished steel per year), i.e. minimizing costs by synchronizing the hourly productivity of all units.

13

. The use of high-performance mechanized small-section and small-section wire mills with a small number of service personnel allows, when commissioning a single technological line (from steel melting to rolled products), to significantly reduce the cost of production.

14

. In mini-factories, the highest return from the implementation of integrated automated process control systems, which ensures increased productivity and improved product quality, while in large integrated plants, despite significant costs, it is not yet possible to link together the control of all technological processes [23].

15

. Higher level of profitability. According to the non-profit organization International Institute of Steel Industry (IISI), American full-cycle steel mills had a profit margin of 7% in 2000, versus 22% for mini-mills.

16

. The advantages of mini-factories in terms of specific capital investments become even more obvious if we take into account the need to solve environmental problems that are becoming global. The main harm is caused by functioning sinter plants and coke-chemical production plants operating in full-cycle plants, the absence of which turns metallurgical mini-plants into industrial formations that are absolutely harmless to nature [24]. Air pollution is reduced by 86%, and water pollution by 76%. In modern conditions, full-cycle metallurgical plants require huge amounts of money to cover the costs of environmental protection. Often, the cost of solving these problems can be compared to building a new mini-factory. For example, in the USA, specific capital investments for equipment that ensures environmental protection for integrated plants are 400–650 dollars/t, and for the construction of a mini-plant – 70–150 dollars/t.

Thus, the competitiveness of mini-factories is achieved due to high profits per unit of production (despite higher production costs), obtained due to low specific capital investments, optimal use of production equipment, flexibility of the technological scheme, elimination of wasteful expensive transportation and a high degree of automation of production processes.

The issues of restructuring the metallurgy industry in Ukraine are also important. Without its own economically efficient metallurgy, the security of the country is undermined, which can lose its status as an industrial power and turn into a raw material base and an object of expansion of foreign capital. Therefore, it is necessary to “facilitate” the industry and restructure inefficiently operating capacities. The way out of this situation seems quite obvious, since there are sufficient conditions for the development of the concept of mini-factories in Ukraine, which has the necessary capacities, raw materials and qualified labor. In addition, according to known forecasts, in the near future the amount of secondary metals in Ukraine will increase [25].

To illustrate the economic feasibility of organizing mini-factories in Ukraine, comparative economic and financial indicators of full-cycle plants producing similar products with a mini-factory are presented (Table 1.5).

A comparison of the presented indicators makes it possible to state that CJSC MMZ Isteel (Ukraine) has achieved the best indicators of production of marketable products and profitability of sales, and also only at the mini-plant financial indicators correspond to the recommended ones.

Table 1.5

. Economic and financial indicators of economic activity of metallurgical plants, combines and mini-plants in Ukraine for 9 months. 2002

Taking into account the above, taking into account the availability of the necessary resources, the advantages of the mini-plant concept for the metallurgical complex of Ukraine, which requires reconstruction, seem quite obvious.

| 1.1 The role and place of metallurgical mini-plants in the overall structure of ferrous metallurgy |

Souvenir products

To create a mini production for a small business with their own hands, some entrepreneurs use their talent and creativity.

We are talking about making souvenirs. If you decide to start such a business, you must first decide on the range and purpose of the products. To start you will need approximately 5 thousand dollars. If the circumstances are successful, the production of souvenir products will pay for itself within one year. To reduce costs, you can start working at home. A talented person can turn any trinket into a real work of art. Since handmade souvenirs are valued much higher, at first you can do without the use of special equipment. If you sell finished products on the Internet, you will not have to register an individual entrepreneur and pay taxes. In the future, with successful business development, it will be possible to officially register your activities and expand sales channels for finished products (establish wholesale sales).

Other good ideas

There are a huge number of home production ideas. Mini-businesses can be developed in the following areas:

- production and sale of handmade jewelry;

- making gift bouquets from sweets, toys or banknotes;

- production, sale and rental of life-size puppets;

- production of modular paintings;

- dry felting of wool;

- making handmade soap;

- breeding aquarium fish;

- production and sale of dumplings, dumplings and other semi-finished products;

- decoration of wedding glasses;

- production of pillows for pregnant women;

- sugaring or waxing;

- knitting toys from plush yarn;

- production of designer covers for documents;

- making refrigerator magnets from polymer clay;

- making sleep masks;

- knitting to order;

- making decorative candles;

- production of exclusive chocolate;

- production of souvenir ships;

- production of clothing and furniture for pets;

- production and sale of home preserves.

Small Business Equipment

Almost all new production ideas for small businesses require the use of special equipment. Imported equipment is not cheap, so many businessmen try to purchase it from domestic manufacturers. The modern market offers a wide range of different units and machines for home businesses:

- Mini-factories;

- Furnaces;

- Machines for the production of cinder blocks;

- Production lines for the production of plastic tableware;

- Technological units for the production of primers, varnishes and paints;

- Boilers and more.

This type of equipment is in great demand in our country, so if you start producing equipment for small businesses, your enterprise will generate excellent income. Familiarize yourself with the design of various machines and units, choose an acceptable option and get to work. There is not yet much competition in this market segment, so any novice businessman can ensure high profitability and prosperity for his enterprise.

Prospects

In conditions of a sharp decline in demand for metal products, the majority of mini-mills put into operation remain stable. A number of them manage to maintain nominal production volumes. Some others experienced a decline of 30-50%, which should be considered as a signal of the need to increase the competitiveness of products. It is noteworthy that new metallurgical plants have appeared in Kazakhstan, Turkmenistan, Azerbaijan, and non-metallurgical regions of Russia. These businesses are strategically targeted to specific market niches and can pose serious competition to traditional steel producers by virtue of their advantageous geographic location and exploitation of local conditions. It should be expected that the construction of mini-factories in the CIS (including Ukraine) will continue even in difficult crisis conditions. However, preference will be given to plants with small productivity. For example, recently in Ukraine the AZOVELECTROSTAL plant (Mariupol) was successfully launched and a casting and rolling plant in Pavlograd is preparing to launch.

- ← Experience in introducing service maintenance for linings of thermal units at OJSC ChMK

- Small electrometallurgical enterprises in the structure of the steelmaking complex of Ukraine →

Donuts

Do you want to open a profitable mini-production for a small business? The most profitable, but at the same time the most risky field of activity is the production of food, and in particular, donuts. If you do not sell such products on time, they may deteriorate or lose their attractive appearance, which means that your company will suffer losses. Therefore, if you want to set up the production of donuts as a business, you must first conclude contracts for the supply of finished products. Finding regular customers is not so difficult, since there is practically no competition in this area. Donuts can be sold in bulk to stores, catering establishments, schools, or sold through your own retail outlets in the market. Such profitable production for small businesses allows you to earn decent money literally from scratch.

Decorative swirls

Arranging the territory of a country house is an important undertaking. We have long been accustomed to the various landscape beauties on it in the form of alpine hills, hedges, and artificial reservoirs. I want something no less beautiful, but much more original. We suggest you start making cute installations with a vortex whirlpool.

Such illuminated decorative whirlpools can be used both outdoors to decorate courtyards, and indoors, made as night lights.

Everything you need to make them can be found at any hardware store.

Photo albums

If you're interested in the latest small business manufacturing, take a closer look at photo book and photo album making. This is a great idea that can be implemented at home without significant financial investment. Nowadays, many people are interested in photography, so they need somewhere to store their best work. Pictures collected in a beautiful original album look much more respectable than on a flash drive. This book for pasting photographs can be given as a gift for a wedding, birthday or anniversary.

If you decide to start producing photo albums, you can make stylish books for sale and to order. To begin with, make several high-quality works and hand them over to a bookstore or gift shop for sale. To attract customers, you need to advertise in the media or offer your services on social networks. This business is suitable for creative people who are passionate about photography. This work requires imaginative thinking, discipline and perseverance. If you have such qualities, you can safely open a mini-production in a private home.

Cupcake bouquets

What do most women adore? Of course, flowers and sweets. Now we will tell you how to combine this together and make the lady of your heart a little happier.

The essence of the idea is to make very impressive bouquets that are quickly made from cupcakes. Any girl will be pleasantly surprised by such a gift.

An excellent alternative to other options for edible bouquets, which sell well through pages on social networks.

You can buy cupcakes for these bouquets, in which case they can be made very quickly, or bake them yourself according to the author’s recipe, in which case it is more likely that they will come back to you again and again.

To make bouquets you will need the cupcakes themselves, cream, bags for applying it, skewers, decorative buckets and balls (they are easy to find on the Internet).

Next, we look for clients online, receive an application, create a fresh, delicious bouquet in a short time and send it for delivery.

Jam

Many people do not even suspect that jam production as a business can bring good, stable income. Despite the high level of competition in this area, newcomers can easily find reliable distribution channels for such sweet products, since the demand for them never decreases. Various jams and preserves are used to make confectionery, sweets and semi-finished products, so many food industry enterprises purchase such goods in large quantities. This profitable production for small businesses will generate income in any locality. It is most profitable to open such a business in rural areas. In this case, you can use fruits and berries from your own garden as raw materials.

Disadvantages of a Home Business

Before starting private production at home, it would be useful to familiarize yourself with the disadvantages of this type of activity. Here are the main ones:

- The difficulties of self-discipline. It's not so easy to plan your day wisely. But it’s even more difficult to force yourself to follow the plan without pressure from the outside.

- Lack of communication. Man is a social being. Working from home, there is a severe lack of contact with other people.

- No guarantees. You cannot be 100% sure of the profit amount. In addition, in the event of temporary disability, you will not receive any payments, but will be forced to live on personal savings.

- Lack of awareness. At the initial stage of work, most people have an insufficient set of knowledge.

- Slow growth. You must be prepared for the fact that your earnings will be unstable at first. It will take some time before you develop a clientele and reach a high level of income.

Wicker furniture

If you often think about what kind of production you can open with minimal investment, try organizing the weaving of wicker furniture with your own hands as a business. Any person can do this kind of work. If you do not have money to purchase raw materials, you can prepare it yourself. In order to master the skill of wicker weaving, use special literature. Another option is free master classes from folk craftsmen on the Internet.

To begin with, you can practice making small baskets, souvenirs, pots and other small items. If everything works out for you, you can start organizing small business production. Select a room for a workshop, purchase the necessary professional tools, and also create your own website where customers can order furniture or souvenirs. According to experts, this is the most profitable production for small businesses, since it does not require any financial investments. All you need for the job is your time and skillful hands.

Homemade wine production

If you are thinking about starting a production facility in a private home, wine is the ideal product for you. A high-quality homemade drink cannot be compared with those sold in stores. Sometimes it seems that the buyer is paying for a bottle with a beautiful sticker, and not for the wine. Therefore, your idea will resonate with connoisseurs of quality alcohol.

Wine production in a private home will be a particularly good idea for those who have a plot of land from which they can collect fruits and berries in large quantities. It is also important that you have a suitable utility room. The business promises to be profitable, but the initial investment is not small. To get started, you will need at least 200 thousand rubles, part of which will cover the following needs:

- purchase of fruits and berries (if you don’t have your own);

- sugar;

- fermentation bottles;

- electric choppers and juicers.

Significant costs will be associated with documentation. Namely:

- registration of a legal entity (namely LLC);

- license for the production of alcoholic beverages;

- permission from the sanitary and epidemiological station;

- certificates of conformity for each batch of products.

When registering, you need to indicate several OKVED codes, namely: 19.93 “Production of food products”; 01.13.1 “Production of grape wine”, 51.34.21 “Bottling of the finished product”. When choosing a taxation system, give preference to a single tax.

How much can you earn from homemade wine? The average price per liter is about 200 rubles. If you produce a high-quality product that will find its regular customers, you can earn over 100 thousand rubles per month. On the eve of the holidays, profits increase significantly.

Compound feed

Due to the development of agriculture, the demand for balanced feed for poultry and animals began to grow.

Therefore, it is not at all surprising that the production of animal feed is one of the most profitable areas of business activity. Such products are purchased in large quantities by farms, intermediary companies, nature reserves, zoos and individuals who have their own household plots. To enter this business, it is enough to purchase a small production line, purchase raw materials for the production of feed and find permanent markets. It is more profitable to open such a business in rural areas. This will allow you to significantly save on transportation costs.

Making cottage cheese

A very profitable option for a small business, especially if it is possible to sell products in large cities with good demand for home products. To produce from scratch, you will need a separate room and special equipment (electric pasteurizer, curd bath, etc.), the purchase of which will cost 1.5-2 million rubles, plus the cost of raw materials and preparation of the production facility.

We receive a minimum starting capital of 3 million rubles. However, the net profit with a monthly output of 13-16 tons will be about 200-300 thousand rubles, which means that investments in the business will pay off in 1.5-2 years.

Semi-finished meat products

Food production generates decent income even during an economic crisis. The most profitable activity in this area is the production of semi-finished meat products. These products are very popular among domestic consumers, so such a business will generate decent income. To organize the production of dumplings at home as a business, you do not need special equipment. At first, such products can be made manually. Over time, when the enterprise begins to develop, you can purchase a production line and hire assistants. To increase the profitability of the enterprise, organize sausage production as a business. To do this, you will have to purchase additional equipment and obtain the necessary permits.

Small factories - examples

In Russia, mini-factories are very popular among budding entrepreneurs. This is due to the fact that this type of business requires minimal investment.

And besides this, miniature factories attract investors as extremely profitable projects.

№1 Construction. With new homes being built every day across the country, construction is the most popular niche to start a business. You can purchase a plant with a narrow focus, for example, for the production of bricks or paving slabs.

#2 Making food. Food is always very popular, so it is better to purchase factories in the following areas:

- Meat processing;

- Dairy products;

- Confectionery.

No. 3 Waste recycling. This problem has always existed in Russia. This industry is actively developing, and a big plus is that it is extremely easy to obtain government approval to conduct this type of business.

No. 4 Light industry. People began to pay more attention to their appearance. By purchasing a mini-factory and starting to produce textiles, you can easily recoup your business.

Whatever industry you work in, remember that the most important indicator is your knowledge. The more knowledge you have in any direction, the easier it will be for you to develop.

Now it’s worth presenting in more detail examples of mini-factories that are most popular among entrepreneurs.

Brick Factory

And first, it’s worth talking about the cost of such equipment, it is approximately 1 million rubles. In some cases the cost will be slightly higher. Additional costs include the purchase of additional equipment and raw materials to start production.

Let's look at an example of production. To make 1,000 bricks we need 800 kg of cement, 300 liters. water and 3,000 kg. raw materials. In addition, you will have to spend money on paying for electricity, since this type of equipment has a lot of power.

As is clear from the example, the plant will consume a lot of financial resources, but the costs quickly pay for themselves. The profit from such enterprises can be so great that entrepreneurs have to expand production to several factories, and this brings even greater profits.

Feed production

The option of opening a business in a rural area will be extremely profitable, since you will immediately find buyers and will not spend money on transporting goods.

Special equipment will process and crush grain. The quality of the final product directly depends on the size of the sieve in the crusher. There is no need to worry about the premises for the plant; a garage or hangar is perfect.

A good location near agricultural enterprises will not only provide customers, but will also serve as a place to purchase raw materials.

Concrete production

To organize production you will need a concrete mixer. With its help, it becomes possible to obtain a higher-quality output product. This type of plant is perfect for large enterprises that do not want to depend on cement suppliers. This solution will help you save money.

In addition, the high mobility of mini-plants for the production of cement makes it possible to move them from one construction site to another. Transportation can be carried out using a truck or tractor.

The purchase of such equipment is available not only to large enterprises, but also to private individuals.

Production of foam blocks

A material that is rapidly gaining popularity in the construction industry. The equipment for its production is very similar to a concrete mixer, but there are some differences. A distinctive feature is stirring the mixture so that there are bubbles in the final product. This task lies with the foam generator.

The main expense item will be the purchase of cement. Important! Before opening such a business, make sure that you have a trusted concrete supplier who works on favorable terms.

The production of foam blocks is very attractive to novice businessmen, as it does not require complex production technologies.

Milk production

Of all the options listed, milk production is the most difficult. Such an enterprise is a whole complex that has several stages of production. Accordingly, you will need to purchase special equipment to create a full-fledged enterprise.

The scale of processing depends solely on the size of the plant itself. The mini-plant is capable of processing up to 25 tons of milk per day. This makes it possible to produce other products, such as cottage cheese or sour cream.

When opening such an enterprise, you need to clearly understand how much raw materials you will be equipped with. Speaking about the premises, we can say that a small workshop or garage is perfect.

Mini-factories are deservedly popular in agriculture. Farmers often buy them. Here there is a reasonable price and the opportunity to sell not just raw materials, but a complex processed product with a higher cost.

Garbage recycling

This type of activity is gaining popularity in Europe. The reason for its popularity is that the population in such countries is growing rapidly, and this is reflected in the amount of waste produced. In addition, the world's population is extremely concerned about the environmental situation, which gives rise to the emergence of such enterprises.

It is worth noting that such a business attracts the attention of not only the public, but also the state, and this can significantly complicate the process of obtaining documents. It may take several months. Among the necessary permits, it is worth mentioning: permission from the Ministry of Environment, Sanitary and Fire Services.

Opening a large production facility will require serious investments, but you can open a mini-factory that will process one type of waste. Let's take plastic recycling as an example.

You will need:

- sorting unit;

- conveyor;

- press;

- stock.

A large number of mobile lines are created for waste recycling.

For example, machines for the production of fuel briquettes from wood waste from a construction site or carpentry shop. A small machine that can be placed on a trailer and brought to the desired location. 10 minutes of deployment and configuration and the line is ready, which will create very expensive and sought-after products from waste.

For many enterprises, a small mini-plant for waste disposal not only complies with environmental standards, but also provides additional income.

It is worth saying that you can improve your business and purchase additional equipment to improve the quality of your products. Modular containers are also often used for mini-factories - this allows you to cheaply and quickly expand production as needed.

Brick

If you want to open the most profitable production for a small business, pay special attention to building materials, and in particular, to the production of bricks at home.

As practice shows, such a mini-enterprise pays for itself in the shortest possible time. Therefore, we can safely say that this type of business is quite promising and highly profitable. Modern mini-brick production enterprises are safe and absolutely harmless, so at first you can do this business at home. This will allow you to significantly save on renting premises. The most important thing in this business is the sale of finished products. If you do not find regular buyers, the enterprise will remain idle, and this will entail serious losses. It is advisable to enter into an agreement for the supply of finished products with a large construction company. In this case, you can count on a constant monthly income.

To increase the profitability of the enterprise, you can simultaneously organize the production of decorative stone. There has been a great demand for this building material recently, so there will be no problems with its sale.

Description of the mini plant

Modern entrepreneurs have great opportunities. To start producing something, you no longer need to build huge factories and hire several thousand people. The development of technology has made it possible to reduce production lines several times. Such technological complexes are called mini-factories. They are modules - different parts that are connected into one production line. The capabilities of such equipment are wide:

- you can upgrade by purchasing new modules, thereby expanding the range of products;

Mobile mini plant - manufacturers make equipment fully automated, which significantly reduces the share of manual labor - workers are needed only at the stages of loading raw materials, quality control and acceptance of finished products;

- The equipment set is compact and does not require large production areas;

- mobility is another advantage; ease of assembly and transportation allows production to be located in close proximity to potential consumers. For example, a mini-factory for the production of concrete blocks can be installed near a large-scale construction site and not spend money on delivery;

- the equipment operates with great efficiency, the percentage of defects is reduced due to automated control, as well as economical consumption of raw materials. This is more profitable for small businesses and increases profits;

Approximate cost of a mini plant - technological lines are developed in such a way as to reduce possible emissions of harmful substances into the environment. Environmental friendliness is another advantage of mini-factories;

- the cost of opening a small production facility requires much less capital investment. Firstly, the line itself costs several times less, and secondly, you can place it in a rented premises rather than purchasing your own (since the equipment is portable and compact);

- a mini-factory can produce exclusive products in small batches, and such goods have a higher price, accordingly, the enterprise will have more profit;

- due to relatively small capital investments, a small business pays for itself in a short time (from one to three years) and subsequently brings net profit;

- the sale of imported equipment is carried out by domestic intermediary companies - this greatly simplifies the process of selection, ordering and organizing delivery.

Work on a mini-line for the production of aerated concrete