Bookmarked: 1

Self-leveling floors 3-D - photo example.

Production of self-leveling 3-D floors as a business idea for startups with small start-up capital.

This type of business is attractive and profitable for beginning businessmen, primarily because it does not require too much initial investment. And the demand for this kind of unique creative service is increasing every day. You can also familiarize yourself with a business idea for selling doors with a 3-D effect.

What is a decorative polymer floor?

The advantage of such a floor is strength and durability. In order to create such a coating, polymers based on polyurethane and epoxy resins are used. They are mainly used to cover floors in apartments, but can be found in shops, offices, restaurants and other public places.

The components included in this coating have a high level of fire safety and are hypoallergenic - that is, completely harmless to the elderly, children and animals.

Types of self-leveling floors:

- With Figure 3 - d (which will be discussed in this article)

- Regular graphic image

- Photo printing

- Decorative floor with inclusions (coins, various types of decorations)

- Plain floor without pattern

- Imitation of natural materials - wood, decorative stone

- Hand painted.

Facts about self-leveling floors

Decorative self-leveling floors have recently become popular

Attractive appearance, the possibility of long-term use, resistance to moisture - all these are the characteristics of self-leveling floors. It is made from a polymer coating with the addition of polyurethane or epoxy resins. Polyurethane floors are prone to fading in the sun and are often scratched by heels and cannot be repaired. Therefore, it is more profitable to purchase epoxy floors with greater resistance to sunlight, and scratches on them can be easily resolved by sanding.

Previously, decorative floors were most often laid in restaurants and fashionable offices, but now they can be found in apartments and private houses. Self-leveling floors do not contain toxins, so they cannot cause allergies, and also meet fire safety standards.

Advantages of self-leveling floor

Why are self-leveling floors in such high demand? Firstly, they are environmentally friendly and safe, which attracts people who care about their health. Secondly, they have a spectacular appearance, which gives individuality to the house and apartment. Self-leveling flooring is considered an expensive coating that can replace laminate, tile and linoleum. Thirdly, this type of coating is resistant to mechanical damage, waterproof and antibacterial (due to the dense structure, there is no place for bacteria and fungi to reproduce). Therefore, it is an excellent solution for wealthy clients.

Manufacturing process

Such work requires special knowledge and skills

The quality of self-leveling floors depends on the qualifications of the personnel who will make them. Such work requires special skills and knowledge, as well as experience and skill. If experts allow particles or air to get into the resin, the self-leveling floor will be damaged. Therefore, before starting the polymer application process, the floor must be cleaned and prepared.

The surface of the future floor must be covered with a screed, which will make it perfectly flat. After leveling, the first layer of resin is applied and it is allowed to dry. When the surface dries, it is necessary to polish the top layer; sometimes it is necessary to additionally coat the floor with varnish. The speed of manufacturing the self-leveling floor will depend on how professional your team of workers is; ideally, this process takes no more than one week.

Remember: The salaries of specialists must correspond to the level of their skills, otherwise employees will go to your competitors.

The order completion time depends on the professionalism of the workers.

In order to start working, you need to prepare the following materials:

- impregnation;

- soils;

- waterproofing;

- finishing coating.

Also, special tools are needed to produce self-leveling floors:

- spray gun;

- squeegee;

- milling machine.

Experts advise at the initial stage to rent a milling machine, or try to do without it, since the price of the device may be prohibitive for a novice entrepreneur.

Hand tools and accessories

They are necessary both for work on large-area objects and for pouring in apartments.

- Needle roller. Used to level the mixture and remove air from it. Allows you to pour the solution into hard-to-reach places.

- Raklya. With its help, the mixture is quickly leveled over surfaces. Increases labor productivity and speeds up the pouring process. It has several blades that are fixed on the tool with special clamps.

- Putty knife. Small sizes allow you to work in corners and other areas with complex geometry. Felt covers are used to smooth out decorative elements on the floors.

- Needle stools. They are worn on workers' shoes, allowing them to move safely over the fresh layer and not leave marks.

- Sclerometer. It can be mechanical or electronic; it allows you to measure the hardness of concrete bases - a prerequisite before applying finishing coatings. Weak concrete provokes the appearance of defects. Their elimination will require a lot of time and effort, and traces of defects may remain.

- Moisture meter. Measures the moisture content of concrete and indicates the completion of chemical reactions in the solution.

- Pyrometer. Measures the temperature of surfaces, necessary to check the readiness of the base for pouring.

- Level. It can be tubular, bubble or laser. Laser is most often used - it speeds up the process of checking the bases and controls the thickness of the finishing layer.

- Rangefinder. Used to simplify calculations of the required volume of materials.

Mixing the components requires special containers; the volume depends on the size of the floor area and the capabilities of the builders.

When pouring floors in winter, it is necessary to use heat guns, either gas or electric. With their help, rooms are heated to recommended temperatures. You should use a heat gun very carefully, avoid overheating and uneven heating of the base. Areas with high temperatures harden quickly, creating difficulties during pouring. Another problem is the rapid evaporation of moisture, and some compositions require it for the polymerization reaction.

Each master works with his own list of equipment and tools, choosing the one that he is used to and trusts. There is no need to strive to purchase the most expensive; quality and performance have no direct connection with price. It all depends on the professionalism and skill of the builders; this must be kept in mind when preparing to pour the floors.

4.07.2020

Seasonality

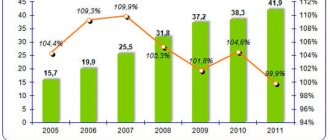

The production of self-leveling floors is a seasonal business.

The business of producing self-leveling floors is considered seasonal, since the main orders are received in the summer; in the spring and autumn, clients appear very rarely, and by winter they disappear completely. Therefore, in order not to be in the red due to salaries, you can hire a team for the season (for example, from April to September), or look for employees on a piece-rate basis (a percentage of each order). To begin with, you can complete several orders at reduced prices to gain experience and understand the process.

Professional approach

MDV GROUP offers professional equipment that has many functions and allows you to create excellent quality floors. These are machines and tools from reputable manufacturers Kreber, Wacker Neuson, Husqwarna, Nilfisk, Splitstone, Schwamborn and others, which have received high recognition in the market. We offer equipment that we are confident in and that we use to carry out the work ourselves.

We not only supply products from well-known brands, but also provide services for arranging industrial floors of various types. That's why we always have equipment that has proven itself in the most complex processes.

Job requirements

The self-leveling floor is laid on a concrete or cement base, and the moisture content of the concrete should not exceed 4 percent. Before starting work, it is necessary to clean the surface of old coating, dust and other contaminants. During installation, a constant temperature must be maintained to prevent condensation from appearing and damaging the floor. There should be no cracks, breaks, chips or potholes in the base, otherwise the technology will be disrupted. The most common mistake when laying a self-leveling floor is the presence of film and cement laitance on the surface, which entails detachment of the base of the self-leveling floor.

The process can even be carried out independently, provided that simple technology is studied. There are the following main stages of laying a self-leveling floor:

- preparation of the concrete surface;

- applying primer and impregnation;

- putty;

- filling with the finishing layer.

The cost of the work depends on the surface area, as well as the client’s wishes (3D image, photo illustration, design in various colors). Most often, artists and designers are hired for such work and receive a fixed fee for their work.

Orders for self-leveling floors in production workshops bring good income

In order for orders to be constant, it is necessary to take on any work: from apartments to industrial premises. Entrepreneurs specializing in apartments and private houses cut off most of the clients who bring significant income to their competitors. Self-leveling floors in offices and production workshops do not require much imagination or designer work, but, due to the large area, they bring good income to the business owner.

Frequent clients are owners of bars, cafes, pubs and nightclubs, for whom it is more profitable to have a self-leveling floor in their establishment. After all, it has an elegant appearance and is also quite easy to clean. Sometimes we receive orders for liquid bar counters and countertops.

A designer can recreate a paradise of nature in your home

To constantly maintain customer interest in your company, you need to come up with something new and original. For example, there is a transparent self-leveling floor, a floor with three-dimensional paintings, illuminated from the inside.

Experienced designers will always find a way to surprise the client.

Income and expenses

Starting this business does not require large investments from the entrepreneur; the main thing is to equip a decent office for receiving orders, create a good website and hire specialists in the field of floor design and installation.

Initial costs for office renovation, website creation and promotion, production equipment and business registration will amount to no more than 500 thousand rubles. Every month, the business owner will need to pay rent for an office and industrial warehouse, pay salaries to his employees, as well as cover taxes and unexpected expenses. On average, monthly expenses are 200-250 thousand rubles. The income of a company producing self-leveling floors during the season can range from 500 to 800 thousand per month. In this case, the payback of the project ranges from 4 to 12 months.

Manufacturing self-leveling floors is a profitable and interesting niche in business. Designers, using modern technologies, can recreate in your home or office a paradise of nature (a floor depicting a coast, a waterfall, the sky) or a masterpiece of art (copies of paintings by famous artists). That is why the role of owner of such a business is suitable for creative people who are ready to support and develop the ideas of their subordinates, striving for something new and unknown.

Today in Russia the niche for the production of self-leveling floors is occupied uncritically, so if you have a desire, then why not try to make money?

Fifth stage. Marketing and workplace preparation

The franchise owner is interested in promoting your business. You can use licenses and certificates from the franchise owner. This will help you save on licensing costs. You need to come up with a discount program and promotions for your first customers. You need to think carefully about how to attract buyers. The franchisor most often provides you with a website and the necessary advertising (all this is individual for each company). To promote an Internet resource, you will need to think about competent content for your region. In addition, it is important to control the placement of information about you on the company’s main website.

Some franchisors require the opening of a retail outlet/office for operation, which must be beautifully decorated and located in a place visited by target customers. For example, in a construction supermarket. You can consult with the franchise owner about the location of the point (in case there are no such recommendations).

It is also important to take the rental agreement seriously. It is advisable that the landlord does not have the opportunity to increase the rent whenever he pleases. An important point is the possibility of extending the lease term. Frequently changing your location will negatively affect the flow of customers.

A big plus in the business of manufacturing decorative flooring is that it is not necessary to have a warehouse and space for staff. The work is carried out on site at the client, so employees can be at home and come when called. You don’t need a lot of space to store tools, and it’s better to purchase materials as needed to keep them “fresh.”

At this stage, the franchisor must provide training on laying the floor and promoting the company in the region (if provided for in the contract). It is important to find out how many people from you will be able to attend seminars, how often they are held, whether there are advanced training courses, and how much they cost. At first, you can install self-leveling floors yourself, hiring one assistant. Even one person can install a high-quality floor. By working independently, you save on staff and become well versed in the technology yourself. If orders increase, you will be able to train your employees yourself.