We live in an age of actively developing technology. And gradually folk arts and crafts are being squeezed out of our lives. And, perhaps, forging is almost the only craft that not only has not disappeared in the course of technological progress, but, on the contrary, has recently become more and more popular. What is the reason? In demand. Nowadays, forging is firmly connected with the design of residential premises and offices, with landscape design. With the growing number of country and holiday villages, it is difficult to imagine without forged gates and gazebos. Forging is still in demand in the funeral business.

Forging is not only large outdoor products, but also objects that decorate interiors of different styles.

Forging is a synthesis of craft and art, making each item unique.

And therefore, now the business of manufacturing forged products is very promising.

Business relevance

In the minds of many people, a blacksmith is a profession from the past. Indeed, there are few real specialists in their field left, but the demand for forged metal products remains quite large.

To open your own forge, you do not have to graduate from the Stroganov Academy of Applied Arts. The main thing is desire and physical strength. It is much more profitable to open your own forge, since craftsmen in most cases do not receive more than 20% of the total profit while working for other companies. The threshold for entering this business is approximately 5-30 thousand dollars.

Forging production is a specific segment that is not without risks and disadvantages. But with the proper preparation of a business plan, construction of a development strategy and market analysis, you can create a profitable business that will quickly recoup the initial investment.

Purchase of equipment, forge and other tools

The choice and purchase of equipment and tools is one of the most important issues when opening your own forge. You need a lot of tools, and they differ in their purpose:

- supporting;

- punchy;

- shock;

- overhead;

- doubles, etc.

Among the impact tools, there are sledgehammers - they will be needed in various sizes to work with large and small workpieces. You will also definitely need to buy anvils, which are related to support equipment. A blacksmith cannot do without various metal clamps and clamps that will hold the workpieces. You need at least 1-2 pairs of vices. Using an applied tool, metal products are notched or stuffed.

For a large-scale workshop, it is necessary to buy several copies of each tool. In addition to the above, these will include hammers, pliers, punches, chisels, electrodes, welding masks, and an assortment of gloves. It is quite possible that you will need a welding machine and an experienced welder. Another useful device is a spray gun, which will make it possible to paint finished products in your production.

However, the most important equipment is, without a doubt, the forge, which is not without reason called the heart of any blacksmith's workshop. There are different designs of forges that use different types of fuel. Some of them run on regular wood or other solid fuels - coal, coke. In large industries, furnaces that run on liquid fuel or natural gas can be used. There is equipment produced by the EFM concern. His portable forges use liquefied propane. Near the location of the furnace, it is necessary to provide working containers and space for water, slag, coal, and oil.

Types of forging

The degree of heating of the material divides the forging process into two types - hot and cold.

- Hot is used for small products, in places where refined and delicate work is needed, artistic forging. This type of work is highly valued. Such a labor-intensive process allows you to obtain refined details and ornaments. It will not be possible to repeat the same detail twice - there will still be differences. But the main disadvantage of hot forging is the high costs for forging furnaces.

- Cold forging replaces casting or stamping. The process itself is the deformation of the broom without preheating it. This is a less labor-intensive option for the blacksmith and cheaper for the customer.

Experts in this field recommend that novice entrepreneurs start with cold forging, since working with forging equipment for hot forging of metal requires great skill and certain skills.

How much can you earn from artistic forging?

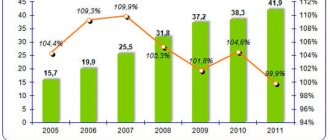

If, at the end of the month, products with an area of 200 square meters are sold, then earnings will be 406,000 rubles.

When registering an artistic forging business, you will need to enter the following OKVED codes in the application for registration of an individual entrepreneur:

- 12 – identifies doors and windows made of metal;

- 62 – regulates services for the processing of metal products using basic technological processes of mechanical engineering;

- 99 – indicates other finished metal products, not included in other groups.

It will be beneficial to work under a simplified system, since an individual entrepreneur or an LLC is registered. Under this system, 6% of income or 15% of the difference between income and expenses will be deducted.

If a blacksmith registers a business for himself, then it is enough to open an individual entrepreneur. If you plan to operate an entire mini-factory with hired workers, then it makes more sense to open an LLC. To register with the tax office, you must provide:

- photocopy of passport and TIN;

- statement;

- registration form;

- receipt of payment of state duty.

There will be no need for additional permits or compliance with state standards, since the production of forged products will be carried out according to individual customer orders.

Such a business is quite profitable if the founder himself is a blacksmith. This significantly reduces startup costs.

Manufacturers of equipment for metal forging provide ready-made kits with which you can organize a blacksmith’s workplace. If you plan to launch a larger enterprise, then it is important to organize everything correctly and purchase several installations.

For a small production facility, a room of about 100 m2 will be sufficient. If you have a garage, you can locate production there. In this case, it will be necessary to rent a small warehouse nearby to store large parts of future designs and finished products (if the customer does not pick them up immediately).

Of course, it is better to locate the workshop in a private sector area where people of above average income live. Another good option would be to place outdoor advertising in such a place. In this case, the circle of potential clients will significantly expand.

If the owner of an individual entrepreneur carries out the work independently, then it is necessary to systematize the receipt of orders and the schedule for their implementation. It is very important in this business to be original and be able to realize any wishes of clients. In this case, work and income will be stable.

Building a strategy

Any business is consumer-oriented - assess the level of demand for forged products. Are there cottage villages or private sectors nearby, are orders from the municipality possible? After that, evaluate competing organizations. These are not only colleagues in the workshop - private forges, but also:

- highly specialized branches of large metal enterprises;

- sale of forged elements from Turkish and European manufacturers;

- Chinese products.

Before opening the forge, describe the following points:

- the number of workshops with a similar direction;

- level of demand;

- possible markets for products;

- approximate number of customers;

- seasonality of the business - is it possible to find buyers in the cold season;

- popular forged products that will be in demand;

- acceptable pricing policy;

- selection and organization of premises for the forge;

- purchase of equipment;

- hiring staff;

- advertising.

Only after finding a definition for all of the above points can you move on.

Where to start an artistic forging business?

Naturally, before starting, you need to take care of an effective financial model and marketing strategy.

You must understand that desire alone will not give the desired result; practical skills of a blacksmith will also be required. They can be learned from experienced masters in special courses.

Art education will certainly help.

Assortment of forged products

The variety of forged products is determined by the abilities of the craftsman.

In our case, the assortment will consist of exclusive furniture, elements for the fireplace, various fences, garden benches, gates, gates, stairs, window and door grilles.

Including other types of products in the range will help increase the customer base.

Business premises

The best place will be the private sector, where famous, wealthy people live. The alternative is an elite residential area.

The minimum area of the object is 100 square meters. It must have ventilation, heating systems, sewerage, water supply, and electricity.

Business prospects

After achieving self-sufficiency, it is planned to open new production facilities, expand the material base, assortment, and workforce.

Financial plan

To open a small forge you need:

- preparation of the premises - 100 thousand rubles;

- purchase of equipment – 300 thousand rubles;

- paperwork – 5 thousand rubles.

Monthly costs:

- rent – 20 thousand rubles;

- tax, utility and transport payments – 20 thousand rubles.

Let's calculate the cost of manufacturing 1 m² of grating:

- purchase of metal – 500 rubles;

- treatment with anti-corrosion mixture – 15 rubles;

- electrodes – 50 rub.;

- utility costs - 100 rubles;

- other costs - 400 rubles.

As can be seen from the calculations, the cost of 1 m² of grating will be 1065 rubles. You can sell it for an average of 3,000 rubles.

If you sell about 40-50 m² of products per month, the revenue will be 80-100 thousand rubles.

The project can be repaid in an average year.

How much money do you need for an artistic forging business?

Let's look at the example of manufacturing forged gratings. The costs associated with the purchase of equipment will amount to 350,000 rubles, of which 250,000 will be spent on the forging machine.

To obtain a product with an area of one square, you need to stock up on rolled metal - 450 rubles, paint - 12 rubles, creative circles - 12 rubles, electrodes - 13 rubles, propane - 5 rubles.

It will cost 48 rubles to pay for electricity, 200 rubles for labor. The amount of overhead costs is 230 rubles. Thus, the cost of producing a square lattice will be 970 rubles.

Clients will be willing to pay for 1 sq. m. not less than 3000 rub. The net profit from the sale of a lattice square will be 2030 rubles.

Premises requirements

For a small scale, it is quite possible to start producing forged products in your personal garage. But keep in mind that even on a small scale, you need a place to store material and finished products. It is also necessary to provide access roads, a place for loading/unloading, and devices that assist this process. Therefore, even at the start, experts in this field do not recommend starting with a garage.

Also note that the forge is not a quiet sewing workshop, so residents of the selected area may be unhappy with the noise. That is why many people move their production premises out of town or to a neighboring village.

If you are going to engage in this type of work professionally, you need to meet the following requirements:

- ceiling height – from 3 meters;

- area – from 80 m²;

- electrical supply;

- availability of water supply and sewerage;

- convenient access roads;

- compliance with fire safety standards;

- ventilation system.

It is convenient and inexpensive to rent former production workshops or forges.

Raw material base

To get started you need to purchase:

- steel blanks (it is recommended to choose low-carbon metal);

- profiles - corners, squares, sheets;

- consumables for processing finished products - primer and anti-corrosion mixture, paints, etc.

All consumables can be purchased in one specialized store. For efficient work, it is better to buy everything at wholesale stores; for larger-scale production, you can find a permanent supplier. Video - Machine for the production of artistic metal products:

Business plan Manufacturing of forged products by cold forging on a machine

Business plan

Production of forged products by cold forging on a machine

Once upon a time, this art was available only to good masters, where, in addition to talent, remarkable strength was needed. Today, huge hammers and hand tools have been replaced by compact modern machines.

A modern blacksmith must be a good artist and designer. Therefore, for a businessman who decides to make money today from artistic forging, it is mandatory to receive an art education. However, the basics of blacksmithing can also be learned fairly quickly from masters or in special classes (courses).

Equipment and raw materials for forging

Universal forging machine - main unit

A universal forging machine is the main unit in production. It is designed both for cold forging, that is, “curling” spirals, twisting metal rods, and for hot forging, for rolling a metal rod and heating it. To work, you must have a welding machine adapted to various types of steel and cast iron. You also need a welding table, a hood and high-quality lighting. You will need an angle grinder (grinder) and an abrasive cutting machine. For painting and crimping products, you will need a piston compressor. Also a workbench and vice, anvil and shelving.

In the future, the list of purchased equipment will be expanded.

Raw materials and consumables:

Billets made of low-carbon steel (St0, St1, St2). Metal profile - square, corner, round timber, pipes. All this can be purchased on any metal base. Anti-corrosion paints, solvents, primers, welding electrodes, cutting and grinding wheels, coke, patina and much more.

Advertising your business has never hurt anyone. It is necessary not only to tell, but also to demonstrate your products on the Internet, on your own website or through social networks, in the media, on advertising banners or street benches, and place exhibition models next to your workshop. Products placed in a prominent place for advertising will be a good invitation to purchase and cooperation. The assortment of products depends on the level of training of the master.

The range of forged products may include:

exclusive furniture, accessories for the fireplace, all kinds of fences, garden benches, wickets and gates, stairs, grilles for windows and doors.

Therefore, it is necessary to include expenses for advertising and promotion of your business as mandatory expenses.

Room

The choice of location for your artistic forging workshop is of great importance. Currently, a large number of expensive dachas and private houses are appearing, in which the Russian elite, successful entrepreneurs or officials live. It is better to place an artistic forging workshop near such cottage villages.

To increase the profitability of your business, you need a premises of at least 100 square meters. meters, which should have running water and electricity. The room should be warm and well ventilated.

For home production of forged products, a private garage or a relatively small workshop is sufficient.

Business equipment

Purchasing a universal machine should be third on your plan. It is not necessary to purchase expensive Western equipment. You can also purchase domestic machines on which you can make simple products - peaks, crow's feet, and baskets. On domestic machines it is also possible to perform longitudinal twisting and curling of spirals.

Optional equipment:

- Drilling machine; Angle grinder (grinder); Welding machine; Forge forge (gas);

- And other improvised devices.

Prospects for further development

The first money you earn must be spent on purchasing the necessary additional equipment, on which the further profitability of your production will depend and will allow you to earn much more:

- semi-automatic press with a force of up to 100 tons, lathes and milling machines, devices for stamping, engraving, molding.

The purchase of this equipment will cost about a million rubles, but this will allow you to increase profitability to a high level. After completing the arrangement of the production base, you can purchase additional materials for production, and this is profitable to do on a wholesale basis.

Rolled metal materials:

Different pipe diameters; A metal sheet; Various sized corners.

Finance

Let's assume that you have organized your production in your own garage with the registration of an individual entrepreneur. The first thing they ordered for you is a forged grille.

The cost of a set of equipment will be approximately 350 thousand rubles, of which 250 thousand will have to be spent on a universal forging machine.

For the production of 1 sq. m. medium complexity grating will require the following materials:

- rolled metal - 450 rubles; anti-corrosion paint - 12 rubles; abrasive wheels - 12 rubles; electrodes for welding - 13 rubles; propane gas - 5 rubles; payment for electricity - 48 rubles; salary for workers - 200 rubles; overhead costs - 230 rubles;

As a result, the cost of 1 sq. m. grating - 970 rubles.

Cost of 1 sq. m. products with elements of figured forging - from 3000 rubles.

Sale 1 sq. m of product will bring you 2030 rubles of net profit. By producing 200 square meters of forged gratings in one month, you will earn 406,000 rubles, thus covering the initial costs of starting a business.

Conclusion

This type of business, such as artistic forging, is becoming increasingly popular in the modern world, and the niche is relatively free. If you like to create things with your own hands, you can take the risk.

Good luck in your endeavors!

Equipment

The most expensive part of the plan is purchasing equipment. You should not save money and choose cheap Chinese equipment. Remember - good tools will last longer and will affect the quality of work. Approximate costs for forging equipment for cold forging of metal plus hot:

- electric hammer – 180-200 thousand rubles (used – 60-90 thousand rubles);

- forge – 70-100 thousand rubles;

- anvil - 10-12 thousand rubles;

- vice - 10-30 thousand rubles;

- grinder - 4-8 thousand rubles. (it’s better to buy several);

- assembly table – 20-26 thousand rubles;

- drilling machine – 15-20 thousand rubles;

- drill (manual or electric) – 4-10 thousand rubles;

- blacksmith pliers – 5-30 thousand rubles. per set;

- machines for cold forging - 10-20 thousand rubles;

- hammers – 1.5 – 4 thousand rubles.

Staff

This business has its own seasonal characteristics, which should be taken into account when working with personnel - in the summer, cold forging products - gratings, fences - are in demand. In winter, artistic metal forging and interior items according to an individual project become relevant.

The forge staff consists of:

- blacksmiths of hot and cold forging;

- welder for joining parts.

Large enterprises have a main staff of a painter, designer, loader, driver, and customer service manager.

Many entrepreneurs who have managed to start a business in the forging industry call the search for personnel one of the most difficult stages. You need to find a professional and responsible craftsman, since the prestige of the company depends on his work. Another pressing problem is that a blacksmith, who has worked for some time, may try to organize production on his own, luring away clients.

The main ways to advertise your services:

- information in the media;

- your own business card website;

- signboard, banner at entry points to private sectors, cottage communities.

Signs and signs with forging elements that your company made independently look great.

When communicating with clients, it is necessary to have a decent portfolio - photographs of finished works. Feedback is also important. Many talented craftsmen do not spend money on advertising and receive clients through word of mouth.

At home

Many craftsmen manage to set up a forge in their own garage and produce products with their own hands.

In this case, it will be possible to minimize costs and not register with the tax authorities.

From manual equipment you will need:

- blacksmith anvil;

- forge - can be welded from sheet metal with built-in refractory bricks;

- hammer;

- vice;

- ticks.

You can start production for yourself and friends, if you like the products and start to be in demand, move on to a more professional level.

How much do you need to invest in opening?

Below are the initial costs associated with opening a blacksmith shop in a small Russian city:

| Expense item | Amount of costs, rub. |

| One-time payment of rent for the first six months | 120 000 |

| Repair and preparation of the forge shop premises for work | 100 000 |

| Preparation of documents, registration of individual entrepreneurs, coordination with regulatory authorities | 20 000 |

| Equipping the forge shop with equipment and necessary consumables | 700 000 |

| Selection of forge shop workers and their training | 20 000 |

| Advertising campaign, including the development of a website with an online ordering function (for “standard” products) | 30 000 |

| Other, including unforeseen, expenses | 10 000 |

| TOTAL | 1 000 000 |

The table clearly shows that the lion's share of the initial capital will go to the purchase of equipment for the forge. And this is quite natural, since modern blacksmiths use not only hand hammers and pliers, but also modern high-tech devices that facilitate and speed up the work process. The remaining funds will be more or less evenly distributed among other expense items.