Printing on mugs and T-shirts is a business with minimal investment. The business is not seasonal, since there is constant demand for products. The set of equipment required to start a business is minimal, and the technology for printing on mugs and T-shirts is very simple.

Mugs with jokes are bought as souvenirs as gifts for work colleagues, friends and acquaintances, for birthdays and other holidays. T-shirts are bought by young people and tourists; there are orders for printing unique T-shirts from enterprises and organizations. It is most profitable to conduct such a business in large tourist cities and metropolitan areas.

What is sublimation on a mug?

At all times, creative people have strived to make all things around them brighter and more cheerful. Modern artists and designers decorate almost everything: clothes, bags, dishes. Thanks to even the most simple drawings, familiar things acquire an unusual flavor. Such items, in particular cups and mugs, become original options for gifts and souvenirs.

Coating technology allows you to apply any design, inscription and even a photograph to the surface of the dishes.

One of the common methods of applying a design to porcelain, ceramics or plastic is sublimation. It is used to apply logos, special designations or ordinary pictures.

For sublimation, a special press and ink are used.

Sublimation on mugs, what is it? Essentially, this technology is image printing, but not direct (that is, without the use of traditional technology). You can apply a design to almost any dish: glasses, plates, vases, etc.

A white or plain mug is best suited for applying a specific design.

Glaze logo print

Hydroglaze, also known as water-based glaze, allows you to create unique dishes, bright and colorful, with original effects. Mahlwerck Porzellan makes several glazing options for logo mugs.

Hydroglaze with logo engraving

Creates a striking contrast for strong branding using any Pantone color, metallic, gold or silver. Engraving can also be done in color, and the surface can be made glossy or matte.

In the photo: a mug with engraving and hydroglaze.

Hydroglaze

Mahlwerck Porzellan technology can be personalized

with full color printing

in opaque Pantone colors without gradients or fine lines. Glossy dishes with this branding can be washed in the dishwasher, but matte ones can only be washed by hand.

In the photo: a mug with hydroglaze and full-color printing.

Hydroglaze with “blind embossing” is an unusual alternative to color engraving: the dishes are first engraved and then covered with hydroglaze. The result is an embossed effect that is great for all images and logos without fine lines.

In the photo: a mug with hydroglaze and an embossed effect.

What is the essence of sublimation technology?

To apply an image to the required surface, special paper is used, on which the desired picture or pattern is already located. To make transfer possible, a special polymer must be applied to the product. After preparing the surface, the image is placed on it and pressed as hard as possible, then it is exposed to high temperature. The paint on the prepared paper penetrates into the top layer of the cup without losing its brightness and shades. This process is called thermal transfer and is impossible without the use of special equipment.

Each person can make an original gift or a unique thing for themselves by applying images to different objects.

Additional ways to apply a logo

Cover for notes

A cup on which you can leave an important note for yourself, a note for a colleague or a message for your family? This exact mug with the logo is in the Mahlwerck Porzellan collection. You can write on it with pencils, and the dishes themselves can be washed in the dishwasher.

In the photo: a mug with a cover for notes.

Metallic effect

A deeper color with a metallic shimmer is a spectacular way to turn an ordinary logo mug into an original accessory. The paint is applied in two layers, providing a more resistant and durable coating.

Nanometallic coating

The elegant shiny finish combined with the engraved logo looks especially impressive. Glamorous silver or gold coating or stylish mother-of-pearl shimmer? Or maybe full color printing? The choice is yours!

In the photo: a mug with a nanometallic coating.

3D printing

Relief printing is a stylish design move and a pleasant tactile sensation. A raised logo or decorative elements can be painted in the same color as the background or differ from it: in any case, such a design will look original and fresh. However, this effect, alas, will not work for small fonts and details.

In the photo: a mug with a three-dimensional logo print.

Combination of matte and glossy finish

A stylish combination of a shiny and matte finish - simple, but very effective! Logo mugs with this design can be made in almost all Pantone colors, creating an original gift in the corporate style of your brand.

In the photo: a mug with a matte and glossy finish.

Stone or concrete effect

Concrete is a fashionable trend in the interior. The effect of stone and concrete is created thanks to special surface treatment. The resulting matte texture, on which deep engraving looks especially stylish, is indistinguishable from real concrete even to the touch. A suitable gift for Builder's Day and other holidays.

In the photo: a mug with a concrete effect.

Swarovski crystals

Elegant kitsch - the mug with the logo is decorated with famous Swarovski crystals. They can focus attention on individual design elements or decorate the entire surface. All work is done entirely by hand!

In the photo: thermal mug with Swarovski crystals.

How much money do you need to start a business?

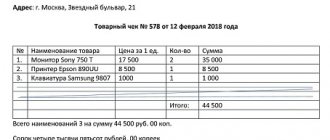

The cost of starting a business will be only 93 thousand rubles. And consumables that are included in the production cost:

- Sublimation ink;

- Mugs (white porcelain);

- Set of cartridges;

- Sublimation paper;

- Clean T-shirt (blank).

Mugs and T-shirts are usually purchased in bulk from their respective suppliers and prices may vary significantly. Typically, cotton T-shirts are purchased for printing, but T-shirts made from other materials can also be used. But the mugs should be porcelain, cylindrical in shape with a photo coating in order to better hold the design.

Types of sublimation

Straight

This printing technology is characterized by the absence of an intermediate carrier with a pattern. The image is applied directly to the surface by mixing paints inside the press. This sublimation requires special printing equipment and is only suitable for flat surfaces. It is used when applying roll on clothes.

In fact, the image becomes part of the dishes: it cannot be washed off, erased or anything else done with it.

Indirect (intermediate)

This sublimation is suitable for products whose shape does not allow them to be placed in a flat-format printer: cups, vases, etc. It provides for the presence of an intermediate medium from which the reprinting process will be carried out in the future.

There are also several printing methods: inkjet, laser, offset and stencils.

How to start a T-shirt printing business

In order for your business to start functioning fully, you will need:

- A computer on which any graphics editor, for example Photoshop, is installed.

- The printer required to transfer the selected design directly to the surface of the T-shirt. This can be a traditional inkjet printer equipped with a CISS, or a printer with conventional cartridges.

- Thermal press

- Plotter for cutting.

But, if you decide to somewhat diversify the range of products offered, then we’ll talk in more detail about T-shirt printing technologies and the required equipment.

Equipment and printers for printing on mugs

Of course, such a business cannot be done with a typewriter.

You will have to spend money on modern equipment, but the scale of these costs is quite small. The total price of equipment for printing on mugs will not exceed 20,000 rubles. Buying a printer for printing on mugs will cost no more than buying a heat press. Of course, this does not include the price of mugs that are intended for painting. When starting this printing business, you will have to understand in detail what is needed to print on mugs. The minimum you will need is the following:

- heat press for mugs;

- Personal Computer;

- a special inkjet printer with an uninterrupted ink supply station;

- initial supply of ink for printing.

But we should talk about all the points on this list in more detail, so that printing images on mugs can be done from the first turn on of the equipment, so that there is no waste of expensive ink, and also mugs.

A printer that can be used to print permanent images on porcelain mugs is called a sublimation printer. After all, the process of printing on mugs is called sublimation. Sublimation printing on mugs is based on thermal diffusion of dye deep into the surface layer of ceramics.

The heat press is very convenient for making products in the form of souvenirs; it has been successfully used for a long time by both professional-level printing houses and centers for the production of documents of special shapes. Often ordinary users are also interested in heat presses. It's all about the simplicity and high quality of the images obtained this way. After all, very high quality products can be created at relatively low costs. The original design of the image is especially important if it is done on dishes and, in particular, on mugs.

A businessman who has mastered the machine for printing on mugs can make good money in the shortest possible time or develop marketing activities. Many people engage in this type of work simply to improve their abilities in artistic creativity. Printers for sublimation printing on mugs are now available to anyone.

Printing mugs come in a variety of sizes and shapes, with glossy and matte surfaces equally suitable for this purpose. Transparent materials and colored ceramic products are also fully applicable. The mug heat press is very compact and easy to use; its working area also has a rounded surface for a tight fit to the walls of the mug.

The control of the machine during its operation and maintenance is carried out using only manual adjustment of the time of fixation of the image on the workpiece. For this purpose, the panel has LED indicators that inform the operator about the degree of readiness of the equipment for work and the image itself after pressing.

Heat presses are produced that are capable of simultaneously creating images on several mugs (from 3 to 5 pieces). Almost anyone can operate a heat press, and this attracts many lovers of original activities to printing technology. Typically, a heat press has a display with which you can adjust both the heater contact pressure and the temperature in the sublimation zone.

Sublimation Printing Equipment

Sublimation transfer of images is the most popular technique among entrepreneurs. This is the best option for those who do not intend to produce mugs in large quantities, but will only fulfill orders from private clients. This line of business is accessible even at home, since it does not require large investments in the purchase of equipment.

Sublimation allows you to obtain full-color images on mugs. At the same time, the print remains on the surface of the product for many years without wearing off or fading. Any graphic image, including a photograph, can serve as a “source”.

Briefly, the technology of printing on mugs using the thermal sublimation method can be described as follows:

- The required image of the required format is printed on special paper.

- Using a press, the sheet is pressed firmly against the mug. Thermal sublimation printer for printing on mugs transfers the image to the surface - the paint penetrates into the top layer of the product.

To start a business, an entrepreneur will need the following equipment for sublimation printing on mugs:

- A computer with installed programs for graphic editing of images.

- Inkjet or laser printer.

- Scanner.

- Heat press.

There will be no problems with buying a computer - to minimize the cost of equipping the interior, you can even buy a used one. The same goes for printing images - the most ordinary printer will do. Well-established brands are Epson, HP, Lexmark. A decent printer model that can withstand heavy loads and reproduce colors well costs at least 5,000 rubles.

The main task is performed by a heat press for printing on mugs - pay great attention to its choice. The market has a huge assortment from suppliers, allowing you to choose the appropriate equipment, taking into account the specifics of your activity and production volume.

Thermal press for cylindrical products is a compact device with a round heated working area. The machine for printing on mugs is easy to operate - a certain temperature is set, the mug is clamped in the holder and held for a certain time.

Heat presses are divided into 2 main groups – vertical and horizontal. The difference between them lies in the way the product is clamped by the machine. According to many entrepreneurs, horizontal heat presses are better because they allow you to transfer images not only to “standard” mugs, but also to beer glasses and vases. But working with unevenly shaped products on a vertical machine will require certain skills - you will have to manually turn the object over, heating one end or the other.

When choosing a press for printing on mugs, pay attention to the following characteristics:

- Quality of the heating element. Great, if it is covered with a Teflon sheet.

- Operating temperature range. The heating limit is usually limited to 240-250 °C.

- Possible number of processed products. There are machines that can simultaneously transfer an image onto 5 mugs at once.

The machine for printing on mugs will have to be adjusted “to suit you” - change the temperature level and the degree of clamping. Each press is characterized by its own characteristics, so at first, prepare for the fact that you will have to act by trial and error.

The price of equipment for printing on mugs using sublimation printing varies in a wide range - from 10,000-100,000 rubles. The specific cost depends on the functionality and the number of “processed” products. Those devices that are equipped with replaceable nozzles for printing on mugs of different diameters are more expensive. Digital control also increases the price of equipment.

Explore the press models on the market to choose the right one. It is better to buy a printer for printing on mugs from a trusted brand. The following brands have proven themselves well in the printing business:

- Transfer Kit,

- Grafalex,

- Insta,

- Bulros,

- Vektor,

- GeoKnight.

Advantages of sublimation printing

Printing using the sublimation technique is one of the most common methods of applying a design to dishes. It has a number of characteristics that make it convenient and practical.

People regularly take breaks for tea and coffee while working, which is why sublimation printing is so common.

Advantages of sublimation printing:

- The design can be applied to different surfaces (metal, glass, ceramics, textiles).

- After application, the image remains in full color. The shades completely match the original version on paper. The drawing remains of photographic quality, and its resolution is at least 300 dpi.

Sublimation on mugs is the application of printing to dishes, which is almost similar to printing text or a drawing on a sheet of paper.

Note! To make a mug with sublimation, it is best to use light-colored blanks. After all, there is no white in her palette. If the background is too dark, the transferred image may change its shade.

- The image obtained as a result of sublimation is distinguished by its durability. It is well fixed in the top layer of the mug. The picture is also not afraid of the effects of chemicals used in the dishwashing process and minor mechanical influences.

Important! To prevent the design from losing its brightness, you should not leave the products exposed to direct sunlight for a long time (about 2 months).

- The heat press allows you to perform sublimation on a small number of cups. It does not require using all its capabilities at once. This makes it possible to produce products in small batches.

Sublimation is a long-discovered process that has gradually begun to be used to create original things.

Hot decal equipment

A mug printing business can be based not only on the heat-sublimation method. Many entrepreneurs use the hot decal method - this is an opportunity to transfer an image not only to ceramics, but also to glass, porcelain, earthenware, and metal. And since the cost of printing on a mug in this case will be higher, the entrepreneur has a chance to earn more. Your clients may be bars and restaurants that need to put company logos on their dishes. The production of souvenirs is often required by large industrial enterprises - for example, breweries.

According to experts, printing inscriptions on mugs using the hot decal method is much better. The image turns out to be very durable - it cannot be erased even with sandpaper. Another important advantage is that the image can be transferred even to an uneven surface.

With the advent of modern equipment, the process has been greatly simplified. Logo printing on mugs using the hot decal method is carried out as follows:

- Preparing the image and transferring it to paper. Ordinary paper will not work here - you need gummed paper with a special impregnation of gelatin. Printing is carried out on digital printers.

- Sticking the finished decal onto a mug. First, a piece of paper with a picture printed on it is soaked in water, due to which the image is easily separated from the base. The paint adheres to the surface of the product.

- Firing a product at a certain temperature. In order for the pigments to penetrate into the material of the mug, it must be exposed to high temperatures.

To produce finished products, 2 main devices will be used:

- Decal printer. Decal printing machines are more expensive than mug sublimation printers. The price of an “average” device is at least 150,000 rubles. To save money, you can buy a used printing machine, but then there will be no guarantee of its durability. The main difference between ceramic printers is that they are refilled with special ceramic ink. In the future, they can also be used to make designer tiles - an excellent option for business development. When thinking about which printer to choose, it would be nice to see it in action. The main criterion is maximum color rendition and the possibility of electronic calibration of the device. Ceramic printers from Ricoh have proven themselves to be a leader in this segment.

- Muffle furnace. These are high temperature chambers used for various purposes. The mugs are fired to secure the prints at a temperature of about 800˚C. The cost of equipment suitable for printing on mugs ranges from 10,000 rubles to 350,000 rubles. There are more expensive devices, but a novice entrepreneur will not need their advanced functionality to simply print photos on mugs. Time-tested brands - SCUTT, KITTEC, SNOL, NABERTHERM.

In addition to the main equipment, the workshop must be equipped with a high-quality ventilation system, since the process must be carried out under special temperature and humidity conditions. This also threatens considerable waste.

Screen Printing Equipment

Screen printing (also known as silk-screen printing) allows you to transfer full-color images to almost any product, including ceramic mugs. Due to the low price of the equipment, this technology is popular among novice entrepreneurs. The method is applicable to both small production and large enterprises. If we compare the quality of images that silk-screen printing and sublimation help to obtain, printing on mugs using the first method is slightly higher in quality - the colors are conveyed much more clearly.

The main difference between this method of image transfer is that the paint is applied directly to the product using special stencils. The process is fast, which is very convenient for clients.

The price of a printer for printing on mugs using silk-screen printing, suitable for small businesses, is 5,000-150,000 rubles. There is a large selection of equipment on the market. The cost will depend on the type of machine. They are:

- Manual. All operations, from setting up the machine to adding paint, will have to be done manually. Such equipment is much cheaper and is perfect for producing small batches of goods. If you master the operation of the printer, the print quality will not differ from that produced by more “advanced” units.

- Semi-automatic. The devices are characterized by more precise printing settings. As a rule, they are additionally equipped with chambers for drying products and a special cooling unit - important functions when producing large quantities of souvenirs. When working with a semi-automatic printer, the operator only manually sets the printing program and picks up the finished mugs.

- Automatic. All operations on such equipment are performed manually. The devices are expensive - novice entrepreneurs may not be able to afford them. This option is more suitable for industrial enterprises with continuous production of printed mugs.

If you compare how much it costs to print on mugs using sublimation and silk-screen printing, the difference will be insignificant. Therefore, we have to fight for every client. To offer customers quality services, choose equipment from trusted brands. These include the following brands – WorkHorse, Lawson, Ming Tai.

Advantages of sublimation printing

Printing using the sublimation technique is one of the most common methods of applying a design to dishes. It has a number of characteristics that make it convenient and practical.

People regularly take breaks for tea and coffee while working, which is why sublimation printing is so common.

Advantages of sublimation printing:

- The design can be applied to different surfaces (metal, glass, ceramics, textiles).

- After application, the image remains in full color. The shades completely match the original version on paper. The drawing remains of photographic quality, and its resolution is at least 300 dpi.

Sublimation on mugs is the application of printing to dishes, which is almost similar to printing text or a drawing on a sheet of paper.

Note! To make a mug with sublimation, it is best to use light-colored blanks. After all, there is no white in her palette. If the background is too dark, the transferred image may change its shade.

- The image obtained as a result of sublimation is distinguished by its durability. It is well fixed in the top layer of the mug. The picture is also not afraid of the effects of chemicals used in the dishwashing process and minor mechanical influences.

Important! To prevent the design from losing its brightness, you should not leave the products exposed to direct sunlight for a long time (about 2 months).

- The heat press allows you to perform sublimation on a small number of cups. It does not require using all its capabilities at once. This makes it possible to produce products in small batches.

Sublimation is a long-discovered process that has gradually begun to be used to create original things.

How much can you earn from selling printed mugs and T-shirts?

- Porcelain mugs wholesale – 38 RUR/piece;

- Paper – 1.5 rub./piece;

- Ink – 10 RUR/piece.

It turns out about 50 rubles for one mug. The markup is usually at least 300%! That is, if we spent 50 rubles on the production of a mug, then we sell it at retail for 150 rubles. The cost of printing on T-shirts is about 150 rubles, and the selling price is already 450 rubles.

You can sell printed mugs and T-shirts through your own retail outlets. At the same time, to open a small department in a shopping center it is enough to rent only 3-4 m2. For example, you can sit in the passage between the escalators, which is about 3 meters wide. Rent in such places is low, since almost no one can fit there. And to sell gift mugs and T-shirts, you don’t need more than 3m2! At the same time, traffic in such places is usually very high.

The outlet's equipment includes several display cases on which cool mugs and T-shirts are displayed. If the place is passable, then people will always “crowd” near your point.

On average, the revenue of such outlets, according to entrepreneurs, is about 6,000 rubles per day. From this amount, you should deduct the seller’s salary (10% of revenue) - 600 rubles, rent - 200 rubles (6000 per month), taxes and other expenses - 500 rubles per day. The cost of the product should also be subtracted from this amount. The total profit of the entrepreneur is about 3,000 rubles per day.

The peak sales of mugs and T-shirts occur before New Year's, on February 14, 23 and March 8. These days, revenue is several times higher. The bulk of the revenue comes from sales of mugs and T-shirts from the storefront. Only 5-10% of the total number of buyers do custom printing.

In addition to selling mugs and T-shirts through your own retail outlets, there are other ways to make a profit:

1. Working with kindergartens. You take a photo of the child and put his photo on the mug, it turns out to be a very good souvenir that many parents are happy to buy. The price of one mug is from 200 rubles, and this is at a cost of only 50 rubles per mug! Profit from one child is 150 rubles, but how many children are there in kindergarten!? The income can be significant, since there are a lot of kindergartens themselves (especially in large cities). All that remains is to come to an agreement with the directors of the kindergartens.

2. Sales of manufactured products in small wholesale to trade enterprises, including souvenir shops and gift shops.

3. Custom printing of branded emblems, logos and other advertising on T-shirts and mugs. Such orders can be made by sponsoring organizations of any events, government organizations, etc.

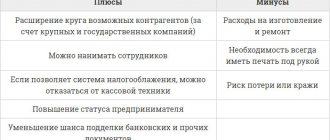

Printing on clothes: profitable or not?

Opening a small T-shirt printing company allows you to get high financial profits. Before embarking on such a project, you should consider all the associated costs. First of all, you should identify all the features of this business and learn about the existing subtleties and nuances. According to statistics, T-shirts are a very popular garment that is used by both men and women. This is why many companies develop unique designs for T-shirts, using employee clothing as an advertising medium.

From this we can conclude that a business based on T-shirt printing will be in high demand. It should be noted here that in addition to working with ordinary citizens, an entrepreneur can cooperate with large companies that will order goods in large quantities. The financial model of this business also has its own characteristics. Many people prefer T-shirts due to their low cost. In the first stages, you can start work with only production equipment. The t-shirts themselves will be provided by people who want to decorate their clothes. Having recouped the initial investment, you can order a trial batch of T-shirts in any of the textile workshops and offer customers ready-made products.

In order to implement this project, you will need to purchase the appropriate equipment. In addition to a computer, scanner and printer, you will need a lot of additional equipment. The total investment in the purchase of office equipment and necessary furniture is about 300 thousand rubles. About one hundred thousand must be spent on the purchase of consumables, raw materials and related costs.

Next you should move on to larger expenses. First of all, you need to find a room where the workshop will be set up. To organize such a business, you will not need real estate with a large area, which will allow you to significantly save on rent. The average cost of renting a future industrial premises is about one hundred and fifty thousand rubles per year. Approximately fifty thousand rubles will be spent monthly on paying employees. Exactly the same amount is needed to cover transportation costs, advertising campaigns and utility bills.

The total cost of registering a business is about five thousand rubles. Experts recommend that beginning businessmen register as individual entrepreneurs, which will significantly reduce the size of the tax base. The amount of annual contributions is about fifty thousand rubles. From all of the above, we can conclude that the total cost of implementing the project will be about 700 thousand rubles. You can reduce costs by purchasing used office furniture or organizing a workshop in your own garage.

Having counted all the expenses associated with organizing a business, you can proceed to calculating your estimated income. The cost of ready-made T-shirts varies from six hundred to one thousand two hundred rubles per piece. As practice shows, entrepreneurs engaged in this business earn about three hundred thousand rubles a month. From this amount you should subtract the monthly costs of renting real estate, employee salaries and utility bills. The total net profit is about seventy thousand. From this we can conclude that the investment will pay off within ten months.

The technical equipment of a mini-workshop is the main point when organizing a business in the printing industry

Which tax system to choose for the business of printing on T-shirts and mugs

To carry out a “legitimate” business, it is enough to register an individual business with the local tax office. The registration period will take no more than 5 working days from the date of submission of documents. The price of the issue is 800 rubles of state duty. As a taxation system, you can choose between a simplified system (STS), a single tax on imputed income (UTII) or a patent. Special data tax regimes will save you from paying income tax, property tax and VAT. The tax burden itself will not be significant.

What is needed for printing?

First, you need to remember that printing on mugs is carried out using equipment such as a heat press and a photo printer. These devices provide fast application of images with maximum accuracy.

In order to carry out this type of work, you need:

- computer;

- a graphic application installed on it in which you can make picture layouts;

- a photo printer that has a continuous ink supply function and works only with sublimation ink;

- sublimation thermal printer for cups;

- thermal tape;

- special paper for sublimation;

- potholder;

- mug.

Selecting mugs for applying images

The quality of sublimation, of course, depends on a combination of factors - equipment, consumables and the mugs themselves. There are many manufacturers of these products on the modern market and they all use different technologies, so the result of applying colorful images may differ noticeably.

For perfect color rendition, it is best to purchase mugs for sublimation of perfect whiteness. Adding a dye whose shade is at least slightly different from the standard white color will change the palette. As a result, you may not get the colors you expected.

For a good even pattern, it is better to use mugs with straight walls of the same diameter. Cone-shaped pans can make the heat transfer process more difficult, especially if you don't have much experience yet. Paper with a pattern often forms folds on such a mug, so immediately after sublimation it will be rejected.

The coating of the mug for application should not raise any doubts. If its surface has an excessively bright glossy shine, it is most likely a thin layer of varnish. By keeping the mug in the heat press for the required time and at the optimal temperature, you can get a good result. But with use and regular washing, the thin coating will gradually wear off, and with it the pattern.

If for your purposes you need a colored mug rather than a white one, pay attention to the uniformity of its coloring. If there are areas where the color is more saturated, most likely stains on such a mug will appear in the future - when applying a design or during use from hot drinks.

Ceramic mugs are susceptible to static electricity. Therefore, at the last moment before the sublimation process, it makes sense to inspect its surface so that there is no dust, lint, or other elements on it.

How does thermal transfer to mugs occur?

| Print the image as a mirror image using a suitable printer and sublimation ink. | Tape the paper onto the mug. | Place the product in a mug heat press, setting the required temperature and time parameters. |

| Carefully bleach the paper from the mug. | Use the mug for its intended purpose. |

Which sublimation printer should I buy?

High-quality ink and a suitable printer are the key to ensuring that the image on the mug will be bright, contrasting and durable. The main requirement for a printer that will be used to print images for subsequent thermal transfer is the ability to use sublimation ink.

It is worth keeping in mind that their composition is thicker than traditional water-based or pigment inks. Therefore, most inkjet printers are not suitable for these purposes. The printing device must necessarily operate on the basis of the piezoelectric method, in which the size of the drop changes along with the magnitude of the current.

This technology is not yet widespread - experts note that today one of the best devices for printing with sublimation ink are Epson printers. The choice of a specific model will depend on other parameters - frequency of use, cost of ownership, speed of printing format.

Choosing a mug heat press

Buying the right mug printing machine will also depend on your end goals. For rare use or sublimation on mugs in small quantities, budget models with one working area are suitable. Even inexpensive models are equipped with a temperature and time control system, an appropriate indication, and a clamping pressure regulator.

For better performance, it is worth using functional devices with several working zones - usually from two to five. Such heat presses will allow you to produce several units of products at a time, while their temperature and time control systems are more advanced.

If you are just starting to master the process of printing on mugs and are looking for the best solution in terms of price and quality, a ready-made thermal transfer kit would be the ideal choice. It contains all the necessary goods - equipment and consumables, which will allow you to get started right away.

Do-it-yourself drawing on a cup

Using the decoupage technique, you can transfer the image you like

on your favorite cup, making it original. Photos, beautiful napkins, illustrations and even postcards will decorate the surface of the mug for a long time. It is necessary to cover the picture with varnish, and when it dries, moisten it in water, from which the paper base will easily peel off, leaving only the varnished image.

Degrease the surface of the cup by wiping it with alcohol, then apply a layer of glass or porcelain glue (depending on the material of the dish). PVA is also suitable for decorating plastic. If you decide to finish the drawing with paints for firing, do not forget to place the product in the oven and heat it at 220 degrees for about 5 minutes. When the cup has cooled down, you can take it out.

Printing on mugs remains relevant due to its wide range of possibilities

drawing images.

There are completely different technologies at your service, each of which has its pros and cons. Choose based on the requirements for the final result. WESTWING shopping club subscribers find interesting offers from well-known manufacturers. They use decorated cups and plates to decorate the walls

of their home. Inspiration is always nearby, join us!

Printing rules

With all these components in place, printing can be done quickly and easily. It is performed according to the following algorithm.

- First you need to change the height of the cup. The height of the applied image should be 5 mm less than the product itself. The width depends on the girth.

- In a graphics application, you must create a file in 300 dpi format. The dimensions are assigned to it according to the parameters of the mug, after which the picture is transferred there. The file is saved in a special RGB mode.

- Next comes the image processing process. You can change it, crop it, add elements to it, and much more.

- You should only print a mirror image of the image, selecting high print quality. The picture should be printed on sublimation paper.

- The image will dry for some time, after which it is carefully cut out, leaving small margins of about 5 mm.

- Next, it is attached to the mug with thermal tape, which must be absolutely clean, without specks. The paper with the design should fit well and evenly, thereby avoiding ambiguities in the design when it is transferred to the surface of the cup.

- The next step is to start working with the heat press. It sets the desired temperature and heating time. The mug is placed in a press and then clamped. After the signal, the product is removed using a tack.

- Next, remove the tape and paper and check the print quality.

Only sublimation ink is used for printing on mugs. It is also important to remember that the picture is applied to the front side of the paper, which makes it look more beautiful.

Printing on cups allows you to obtain bright and original products that look very attractive. You can put any pictures on them, creating an interesting gift or souvenir.

Keywords: images on mugs, printing, how to print, printing on mugs, thermal tape, thermal printer, sublimation, heat press, Printing rules, souvenir, technology, print quality

Decoration method: cold and hot

Hot decal is the application of ceramic paint to the surface and its short firing

at 900 degrees. In a muffle furnace at such a high temperature, the picture is eaten into the layer of glaze covering the cup.

Advantages of hot decal

:

- the printing on the mugs lasts for a long time, without losing its clarity over the years;

- The design can be applied to the entire surface of the product, even uneven ones.

Unfortunately, not all materials can withstand high temperatures. The cold decal method is more suitable for them.

Cold decaling involves applying stickers of the required size

.

The high quality of the image on a mug with a photo has a significant drawback - it is very easily washed off. The method is suitable for dishes and other items that serve only a decorative function

.

How much can you earn by printing on mugs?

In order to calculate the potential profit of implementing this business idea, you first need to find out the cost of production of finished products. So:

Let's calculate how much it will cost us to make one mug:

A mug for sublimation can be purchased at a price of 35 rubles per piece. This mug needs to be printed, the cost of this process will be calculated below:

At the beginning of the process, the image is applied to an A4 sheet of special sublimation paper. The cost of ink consumption is approximately 4-5 rubles per sheet, and the cost of a sheet of sublimation paper is about 4 rubles. It turns out that the cost of printing one sheet will cost us about 8-9 rubles.

On one sheet it turns out to place 3 templates per mug at once, which means 9 rubles need to be divided by three. The cost of printing a template for one mug will be approximately 3 rubles.

Now let's sum up all the expenses:

35 + 3 = 38 rubles, the cost of making one mug! I suggest rounding up to 40 rubles.

Next, you need to decide on the selling price of the finished product. Usually it is about 250 rubles. It turns out that the net profit from the sale of one mug is: 250 - 40 = 210 rubles.

However, the cost of a photo mug can vary greatly. For example, look how much a photo mug costs on one of the Moscow sites. So, when setting the price for a finished product, proceed from the average price in your region or city.

Sell 10 mugs per day and get about 2,000 rubles in net profit. We multiply by 20 working days, and we get a monthly income of 40,000 rubles .

It turns out that having mastered the process of printing on mugs at home, you can earn quite a decent amount of money. And it will be a truly home business.

How to Print Images on Mugs

Sublimation paper differs from regular office paper in its loose structure. During production, it is treated with special chemicals so that it can absorb as much ink as possible. But the backing of such paper is as dense as possible, since the less ink it absorbs, the more ink will ultimately end up on the mug.

If you don't have paper for sublimation printing, you can use regular matte photo paper, such as Lomond. The print quality will be slightly lower.

Armed with a printer and paper, we print out a pre-selected image that will appear on our mug. Important feature: the image must be printed in a mirror image, since when it is transferred from the intermediate medium to the mug, it will again change the horizontal rotation angle by 180 degrees. The image can be rotated and edited in any graphics editor.

Dry the finished image thoroughly. If you use uncured images, ripples may appear on the mug during printing.

We prepare a mug with a polymer coating.

Mug with polymer coating

After making sure that the image is dry, place it on the mug and secure it with thermal tape.

Attach the image to the mug using thermal tape

During heating in a heat press, the glue from the thermal tape may partially transfer to the surface of the mug. Therefore, you should use small pieces of tape.

Place the mug in a heat press and heat it at a temperature of 160°C to 200°C for several minutes.

Cup heat press

We remove the mug from the heat press and remove the paper from it. The imprint should remain on the mug.

Ready mug

If you overheat a mug in a heat press, the image may become blurry, but if you underheat it, white spots may appear on it. Therefore, it is necessary to strictly adhere to the warm-up time specified in the instructions for your heat press. As a rule, it is 1-2 minutes.

If you did everything correctly, you will receive an excellent quality mug with a bright and durable image as a reward.

Samples of mugs with sublimation printing

In conclusion, let us allow ourselves a small lyrical digression. When designing a mug for a loved one, remember his hobbies and interests. An incorrigible romantic or a great lover of adventure, dreaming of distant countries and travel, it is better to give a mug with a beautiful landscape. For a lover of active recreation who appreciates songs with a guitar by the fire, skiing, fishing, hunting, it is better to give a sublimation thermal mug, which will help its owner to relax “in comfort.” For a purposeful person, a careerist with clearly expressed ambitions, the need for self-affirmation and recognition of one’s merits by others, the best gift would be a mug with the inscription: “To the best leader”, “Beloved dad”, “The most faithful friend”, etc.