Manufacturing enterprises are subject to a large list of documents that present requirements for creating comfortable conditions for workers. One of such documents is fire safety rules at the enterprise. Unfortunately, not all owners attach special importance to it, which often leads to tragic situations. But fire safety is a guarantee that nothing will happen to people, provided that all the requirements and rules of this document must be followed.

Primary requirements

Let’s immediately move on to analyzing the requirement, because this is the basis of security. The enterprise must meet the following requirements:

- Determination by order of the head of persons who will be responsible for fire safety, establishing their responsibilities.

- Introduction of fire hazard regimes.

- Completely equip the premises and territory with fire-fighting devices and devices (fire extinguishers, hydrants, sand boxes, fire shields), alarm systems: sound and light.

- Organize training for all employees without exception. Keep a log of completed classes.

- The order approves the procedure for notification and evacuation based on the developed rules.

- Organize the placement of signs, plates with the numbers of special fire services, install telephones in the required places.

The list of requirements is small and does not require huge financial expenditures. But some managers do not even do these little things or do them only in words or on paper. This especially applies to training. But ignorance of the rules is the main reason for the tragic end.

Basic fire safety requirements for an enterprise

The company must meet the following requirements:

- Identification of persons providing control and supervision over compliance with fire safety rules and establishment of their job responsibilities.

- Introduction of fire safety regime.

- Equipping the territory with fire-fighting devices, alarms, fire extinguishing facilities, fire extinguishers, water taps and fire hoses.

- Organization and training of fire safety rules for company employees. Maintaining a log of trainings carried out. Notifying subordinates about the location of emergency exits, alarm switches and alarm buttons.

- Approval of the procedure for notifying personnel in the event of an accident or fire, familiarizing employees with this system. Installation of fire safety signs, signs with emergency numbers and telephones for calling them on the territory of the enterprise and in the premises.

Basic fire safety rules

The list of rules is quite large. But it takes into account all the points that can save people's lives. Their knowledge is mandatory, application in emergency situations is a simple necessity. So, fire safety rules at the enterprise.

- The basic rule for a manager is to organize a fire safety system for the enterprise. To do this, he, by his order, appoints a responsible person who will control everything related to fire safety equipment.

- A study is organized and briefing is conducted, which should confirm that employees have mastered the information received. This especially applies to those involved in ensuring the safety, acceptance and sale of flammable materials.

- All employees who come to work undergo induction training.

- Instructions are provided to review the rules. It must be recorded in the journal. For some categories of workers, examinations are conducted with the participation of a commission. A positive pass guarantees receipt of a certificate (document) of compliance. Mostly workers involved in hot work are subjected to examinations.

- The buildings are provided with alarms and fire extinguishing equipment.

- If there is a leak of flammable materials, the spill area is covered with sand, which is then collected and disposed of. Remains of liquids absorbed into the soil are neutralized with special substances.

- Cleaning of the premises without the use of flammable and combustible materials is organized once a day.

- It is prohibited to block evacuation passages, staircases, service rooms, and corridors.

- It is prohibited to use spaces under stairs for storing household utensils and tools.

- Administration employees also need to strictly follow fire safety precautions - do not store paper near heat sources.

- In the factory area, fire cannot be used for lighting or heating.

- Smoking is prohibited on the territory of plants and factories. For this purpose, places are organized that are marked with signs.

- Access routes and approaches to hydrants and other fire extinguishing means must be kept clear.

Rules for operating technological equipment

Fire safety at an enterprise is a set of measures based on workplace instruction. All workers associated with technological equipment, without exception, undergo it. Depending on the type of machines, their purpose, and the energy carriers used in them, the requirements and rules differ greatly. But there are basic rules that apply to any type of equipment:

- You cannot work on faulty equipment;

- When carrying out repairs or maintenance of machines, they must be disconnected from the power supply;

- Do not clean machines with flammable or flammable materials;

- in explosive industries they use special tools and devices that do not create sparks when in contact with metals;

- Open fire must not be used for any maintenance, repair or operation activities.

Instruction on fire safety at the enterprise

No one has the right to start working until they have been instructed in safe work practices, including a firefighter. During it, employees are provided with information about the correct actions in case of fires, the use of protective equipment, and the conditions for achieving fire safety are explained. Instruction happens:

- introductory;

- primary;

- repeated;

- target.

Induction training is carried out for all employees, permanent or temporary, seconded or students in practice.

The responsible person, who has undergone special training, provides information about the governing documents in the field of fire safety, about methods of fighting fire, and explains the fire safety rules at the enterprise. Practical classes are given.

Conducting fire safety training at the enterprise

The purpose of the initial briefing is to explain how to comply with fire safety in the workplace. The features and procedures in case of fire are explained. It is carried out with newcomers or those who change jobs.

Instruction is carried out individually. When the same type of work is performed by those being instructed, it is allowed to give explanations to a group of people at the same time.

There are repeated and targeted briefings. Repeated fire safety briefings are carried out at certain intervals. It is needed for better understanding and reporting to supervisory authorities. The target is carried out when performing a narrow task.

Conducting training is one of the requirements of fire safety standards. Therefore, its implementation is recorded in the accounting journals, secured by the signatures of both parties.

Rules for employees

The administration is primarily responsible for organizing fire safety measures. But, as practice shows, all troubles most often occur from the human factor, where the main role is played by the ordinary worker standing at the machine. It is he who provokes various situations that ultimately result in a fire. Therefore, the person responsible for fire safety at the enterprise must constantly monitor workers. This is expressed not only in training, but also in constant monitoring of how people work, what tools they use, etc.

Here are a few basic rules that every employee should know:

- he has no right to work unless he has been instructed;

- if the employee is involved in hot work, then he must wear protective clothing made of non-flammable material;

- The enterprise must provide him with such special clothing;

- Do not wash your work suit with flammable or combustible solutions;

- Workwear should be stored in special individual lockers made of steel sheets;

- rags (oiled) used during work are disposed of at the end of the working day or stored in a special metal box, closed;

- Do not wash your hands with solvents;

- you can smoke only in a designated area;

- You cannot work in areas to which you do not have appropriate permission.

The rules are actually simple, you just need to strictly follow them. It is impossible to monitor every worker, therefore, during the briefing process (especially repeated training), special attention is paid to these positions.

Regulations on the Fire Technical Commission

Regardless of what industry the enterprise belongs to, the commission must include employees working in the operation and maintenance of electrical equipment. This should also include employees responsible for fire safety, labor protection and trade unions.

The leadership of the commission is elected at a meeting of members. The activities of the PTC are regulated by adopted plans for a year or six months. After any decision has been made, it must be approved by order of the head of the enterprise. Any activities that are decided to be carried out based on the results of the inspection must be necessarily documented in acts. After this you need to approve. They must be followed by all employees of the institution without exception. According to current legislation, such a commission does not have the authority to cancel or change the requirements of government services in the field of fire safety.

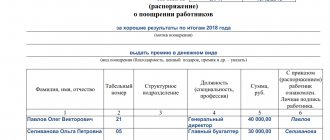

The PTC should regularly report on its work. For this purpose, a general meeting of all employees is organized. If the work of the commission is conscientious, a decision may be made on material or moral incentives for members. An important regulatory document regulating its activities is the regulations of state supervisory authorities, as well as the regulations on the fire-technical commission at the enterprise .

Article sent by: Wladimir01

I like (48)

Articles on the topic

0 40

Portable fire extinguishers. Mobile fire extinguishers. Installation of a fire extinguisher.

Published: June 16, 2017

Legal regulation

Emergency rules

Let's start with the fact that all premises in the enterprise must be equipped with fire extinguishing means. And every employee must be able to use them; he must be taught this in fire safety classes.

So, what should an employee know and be able to do if a fire does start at the enterprise:

- he must call the fire department;

- begin actions to extinguish the fire;

- organize the evacuation of other employees;

- help the victims, that is, apply first aid skills;

- independently leave the burning object through evacuation passages.

As practice shows, it is knowledge of the evacuation plan and routes that creates the conditions to remain alive and healthy. Fire safety in an enterprise is based precisely on this. Already in the background are the possibility of localizing the fire, the use of extinguishing agents, etc. The main thing is to get all people out of the burning building without panic.

Causes of fires in factories

Since fires often occur in enterprises, statistics on the causes of fires have long been compiled.

- 33% relates to violations related to the operation of technological equipment. For example, sparkling parts, poor insulation of electrical wiring, etc.

- 16% is untimely inspection and repair of electrical equipment.

- 13% - poor training of company employees in terms of fire safety at the enterprise, which also includes a poorly organized and equipped workplace.

- 10% - improper storage and use of flammable materials.

From practice we can conclude that not all employees treat their responsibilities as expected. This means that the management of the enterprise must strengthen control over everyone. And here well-developed fire safety rules at work will play an important role.

Complex measures at the enterprise

Comprehensive measures are aimed at increasing the existing level of labor protection at the enterprise, preventing accidents, occupational diseases, emergencies and fires. Compiled at the end or beginning of each calendar year for the coming year.

Note! Coordination with the trade union organization and a labor protection specialist is mandatory. Approved by the head of the company.

High-quality organization of fire safety at an enterprise is the key to long-lasting and productive operation of any production. Therefore, it is important to organize effective work in the field of fire safety and monitor compliance with fire safety rules not only on paper, but also in practice at production sites.

Fire safety checks at the enterprise

Fire-fighting organizations, that is, the Ministry of Emergency Situations, necessarily conduct inspections of companies, regardless of the type of their activity. The main task is to confirm the required state of the company for compliance with the rules.

Types of checks

There are five checks that all companies undergo from the Ministry of Emergency Situations:

- planned,

- unscheduled,

- documentary,

- visiting,

- repeated.

Scheduled inspections include inspections of the facility and verification of relevant documentation. It is held once every three years. Unscheduled are based on a complaint received from any person (individual or legal) to the Ministry of Emergency Situations. The management of the enterprise must be notified of the inspection 24 hours in advance.

Documentary is the same as planned, only during its implementation documents are checked. The company is notified of its implementation three days in advance.

On-site visits, just like unscheduled ones, are carried out on the basis of a complaint, or if inspectors have suspicions that not everything is going well at the enterprise in terms of fire safety. This inspection takes place within 20 days.

Repeated inspections are carried out if, during the previous types, violations were identified, for the correction of which a certain period was allocated. It is at the end of this period that a repeat inspection is carried out, where it is checked how the shortcomings have been corrected.

What documents are checked

Fire safety at an enterprise is a fairly serious list of documents that must be present in full. Missing one is a serious violation. What documents should be available:

- An order from the manager by which he appoints someone responsible for industrial safety.

- List of official responsibilities of the responsible person.

- Order on how to conduct all types of briefings.

- Instruction programs.

- A list of questions that company employees must answer after training.

- A journal in which briefings are recorded.

- Order to establish a PP regime, developed instructions.

- Availability of all technical documentation related to production technology.

- Design and estimate documentation for buildings.

- If the object is leased, then the lease agreement.

- Certificate for the company's activities.

- Certificates of conformity for machinery, equipment and devices.

- Schemes, routes and evacuation plans, several copies, one of which must be posted throughout all premises.

- Rules that ensure the precise use of process equipment.

- Availability of permits and work orders for hot work.

- Acts for carrying out repair activities and their schedules.

Fire safety rules and measures

For different types of professional activities, the requirements for ensuring fire safety in the workplace vary greatly, so it is worth considering several of them for comparison.

in place of an office worker

Undoubtedly, such a workplace, be it the office of an official, a scientist, a specialist in a design or other organization, where the workplace is a table, a chair, a computer and the necessary office equipment, is the safest from the point of view of ensuring fire safety, because there are no, even potential sources of fire threats doesn't exist there.

It would seem that then fire safety in offices and administrative buildings should be recognized as a standard. It is enough to follow the safety rules in public places, because office workplaces are usually located in public and administrative facilities with a large number of visitors, and this will be quite enough to fully ensure safety.

Unfortunately, if this were exactly the case , then fires would not occur in office, business centers, and administrative buildings; workers and visitors did not die, suffocating in smoke, falling to the ground from a height, trying to get out of the premises from the upper floors; Firefighting equipment could be immediately installed on underground hydrants, without wasting precious time taking away personal vehicles installed on their manhole covers.

Most often, the cause of these sad consequences is the notorious human factor, expressed in gross violations of fire safety requirements, which are easy to model:

- On the way to the workplace, a car parked in a fire break, fire passage on the cover of an underground fire hydrant.

- Smoking is not in a designated area, but on the landing, in the basement, technical floor, underground parking, toilet room, wherever it is warm, and unextinguished cigarette butts can be thrown away in any place that catches your eye.

- Stacked in piles in evacuation aisles are annual reports, piles of albums of design and estimate documentation, working drawings, other documentation, as well as third-party pieces of furniture.

- At the end of the work, all electrical appliances were left plugged in - from a computer to a powerful oil heater.

- Ignorance, lack of skills in handling fire extinguishers, fire hydrant kit.

If all the minuses are replaced with pluses, then both the employee and his workplace will not cause any complaints.

at the storekeeper's workplace

Compliance with fire safety requirements in such a workplace is not just a tribute to fire regulations or a fear of control from the management of the enterprise, it can be said that it is a matter of survival in all aspects. From the possibility of not getting out of warehouse premises in the event of a fire, which usually occupy considerable areas with a corresponding length, complex layout of evacuation routes, to the option of ending up in places of detention if the guilt of the storekeeper is proven, the cause of which was significant material damage in the fire.

Therefore, employees of warehouse complexes, logistics centers, and consumable warehouses must be attentive to compliance with industrial safety regulations in the workplace and in buildings in general; avoiding typical violations, pointing out deficiencies to engineering specialists for their immediate elimination:

- Operation of lighting fixtures without closed protective shades, as well as the distance from the fixtures to stored inventory items is less than 0.5 m.

- Open doors of electrical panels, cabinets with electrical equipment.

- Damaged insulation of electrical wiring, mechanical damage to installation electrical fittings - switches, sockets.

- Uncleaned spills of fuel and lubricants and other flammable liquids.

- Storage of containers with flammable liquids, gas liquids, aerosols; cylinders with flammable gases near heating devices or in sunlight.

- Obstruction of evacuation passages and approaches to fire extinguishing equipment; buttons, manual fire call points that serve as triggers for fire extinguishing systems.

- Malfunction of exhaust and general ventilation systems and fire-fighting water supply systems.

- Excessive accumulation of containers and packaging made from flammable materials; failure to pick them up at the scheduled time.

- Placement and storage of inventory items outside of racks, specially marked areas, pallets; and also without taking into account their properties, physical and chemical compatibility.

- Use of gas stoves and any electric heating devices in office and utility rooms.

At the end of the work, all power supply to the warehouse must be turned off, and the electrical equipment necessary for this must be mounted outside the warehouse, on a separate pole/support, or wall made of brick or concrete.

In the event of a fire, people around you should be notified of the danger; report to your immediate supervisor about the incident and immediately report the fire to the nearest fire department, then act in accordance with the emergency response plan. If possible, begin to extinguish the fire using primary fire extinguishing agents.

at the gas station operator's workplace

The safety equipment of gas station personnel must always be at a high level, taking into account regular operations for draining fuels and lubricants into underground tanks, ground storage tanks of a fuel and lubricants warehouse, constant retail sales, distribution of gasoline, diesel fuel, and at some stations compressed combustible gas for refilling a variety of automotive equipment.

Engineering measures to protect gas stations from possible fire are also important:

- Lightning protection of buildings, structures, equipment and communications in accordance with RD 153-39.2-080-01 on the rules of operation of gas stations, including metal cases of ground tanks, containers/fuel storage units; breathing valves, gas outlet pipes and the space above them both from direct lightning strikes and to prevent electromagnetic/static induction, the introduction of high electric current potential.

- External fire-fighting water supply with the installation of underground hydrants within the city limits, if possible, the construction of fire reservoirs, reservoirs or piers; as well as equipping gas stations with mobile/portable fire engine pumps outside settlements.

Shift personnel at gas stations whose workplace is the territory of a building with storage of fuel and lubricant containers are prohibited from:

- Operate faulty, leaky equipment, shut-off valves, instrumentation, as well as fuel and lubricants tanks that have distortions or cracks in their housings.

- Overfill tanks and cisterns when draining fuel and lubricants, and take samples from them during this process.

- Drain or pour petroleum products during a thunderstorm.

- Conduct the bottling of fuels and lubricants, as well as store containers and packaging on the territory of the gas station, including inside the embankment of ground storage tanks.

Gas station personnel are required to exercise extreme caution when carrying out many technological operations associated with increased danger:

- Warming of breathing valves, gas outlet tubes, and cleaning of grids should only be done in a safe way.

- Inspection of breathing fittings and fire arresters should be carried out in accordance with the requirements of technical data sheets and factory instructions.

- Use only spark-proof tools and devices when taking samples, measuring liquid levels in above-ground tanks, underground fuel and lubricants storage tanks.

- Spills of fuel and lubricants should be cleaned up immediately.

Complex events

When talking about such a serious event as fire safety at an enterprise, it is necessary to understand that this is an integrated approach to solving quite important problems. Eg:

- Development of rules. This is done by the manager and responsible persons (experts in their field).

- Implementation of these rules into the life of the company and full strict control over their compliance. This is the most difficult moment, on which the fire safety of production ultimately depends.

- Conduct employee training based on the developed rules.

- Control over technological equipment and utility networks. Particular attention to pipelines through which explosive and flammable substances are transported, as well as electrical wiring.

- Ensure guaranteed protection of workers from accidents. The TB and safety complex is the best fit here.

- Completely equip the enterprise with modern fire extinguishing means. Train workers how to use these tools.

Prohibitions

An integrated approach is an additional designation of what cannot be allowed at the enterprise. Here is a small list of prohibitions, but they must be strictly followed.

- Gas cylinders, flammable materials and combustible substances must not be stored in the basement of buildings.

- If there is no separate exit in the basement, then placing office space or workshops there is prohibited.

- Materials from the flammable category must not be used for other purposes than their intended purpose.

- If the heating system is frozen, you cannot thaw it with blowtorches. This mainly applies to radiators and pipes located indoors.

- As mentioned above, you should not clutter the spaces under the stairs or arrange warehouses and storage rooms in them.

Territory

Fire safety at an enterprise is not only requirements and rules relating to industrial and commercial buildings. It is important to properly maintain the territory. Here are some basic requirements:

- the area must be neat and clean, so it is cleaned every day;

- You cannot use passages between buildings and structures for storing finished products, raw materials or intermediate materials, equipment and machinery; freedom of passage and travel is the main requirement;

- it must always be illuminated;

- access to fire hydrants must be clear;

- it is forbidden to arrange waste dumps made of flammable materials;

- You cannot light fires, if this is allowed for technological reasons, then the distance from the place of burning to buildings should not be less than 50 m.

As you can see, there are a lot of fire safety requirements at an enterprise. It cannot be said that some are less important and other arches are important. All of them must be strictly followed. This applies primarily to management, which organizes safety, constantly monitors it, demanding that ordinary workers follow the rules.

Video: