The saturation of the modern building materials market, the constantly expanding range and the regular appearance of various new products is explained by the very high demand for such products. Moreover, according to statistics, construction will steadily increase its pace in the future.

That is why we can conclude that a business based on waterproofing with liquid rubber is a promising and profitable activity. This innovative material is used to cover floors, foundations and even roofs. The main positive point is the low initial investment. And the right approach to the development of this type of activity allows you to count on a decent and stable income.

Market and competitor analysis

The basis of this business idea is the organization of waterproofing work using liquid rubber. The direction is quite new and does not require significant investments and, by the way, has a very high percentage of profitability.

There are not so many competitors in this market, but the following reasons cannot be ignored, which serve as a significant obstacle to starting your own business:

- high taxes;

- imperfect, complex and confusing Russian legal system.

Technologies

The technology of painting a car body with liquid rubber is simple and does not require special knowledge or highly skilled labor. Main stages:

- The preparatory stage is cleaning the surface of the vehicle, covering areas that do not need to be painted.

- Creating a base - apply the first layer of liquid rubber using a spray gun, leave to dry for 40 minutes.

- Applying the second and subsequent layers.

The treated surface dries for about an hour. After completion of the work and complete drying, you can remove excess residue from areas of the car. After completing work, the vehicle must dry for 12-24 hours. The process itself should be carried out at room temperature without wind, as the spray may be uneven. As you can see, it’s not difficult to coat a car with liquid rubber yourself; the main thing is to adhere to all the necessary conditions.

Production plan

Organizing a business requires purchasing:

- Spray equipment , through which the composition is mixed and subsequently sprayed.

- Personal protective equipment for workers.

Installations for spraying liquid rubber have a fairly wide range, which allows you to choose the appropriate power. The cost of an imported installation exceeds the domestic equivalent by approximately 80-100 thousand rubles. By the way, imported equipment has one significant drawback: it requires exclusively Western raw materials to operate, which puts the entrepreneur within a certain framework and significantly increases the cost of the final product.

The applied rubber contains absolutely no danger to human health, and personal protective equipment is needed because its atomized state can cause respiratory disease.

You should not stock up on professional gas masks, but you should take care of having a waterproof closed suit, rubber boots, gloves, eye protection glasses and a regular respirator. The cost of uniforms for one employee is approximately 10 thousand rubles.

You also need to organize a small office in which employees will be located at times when there are no orders.

When choosing a suitable production facility, the following important aspects should be taken into account:

- the ceiling height must be at least 6 meters;

- availability of communications and power lines of at least 380 kW ;

- area of at least 300 sq. m .;

- the room must be equipped with a good ventilation system.

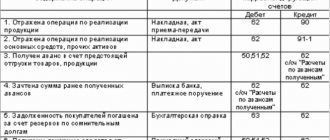

This is interesting: Documentation of accounting for the provision for doubtful debts

The best location is a suburban area.

Assessment of scope of work and order cost

Thus, the task comes down to first applying waterproofing to a horizontal concrete base over an area of 165 m2, and then, after pouring the slab and walls, performing vertical waterproofing over an area of 2x(15+11)x2.5=130m2.

With a waterproofing thickness of 3 mm (corresponding to a liquid rubber consumption of 4.3 kg/m2), the average price for 1 m2 of horizontal coating (labor + material) is 830 rubles.

About the price in Moscow and the Moscow region in the summer season of 2014, which allows a discount for the customer of up to 100 rubles per square meter. If you announce a price of more than 830 rubles, then this will be higher than the market average, therefore there is a possibility that the Customer will not contact you.

Thus, the customer should receive up to 136,950 rubles for waterproofing the foundation slab.

Similar prices for applying liquid rubber to walls are slightly higher, because... the increasing factor is taken into account. Price of service (work + material) per 1 sq.m. for walls is 850 rubles. Thus, for this example, the market cost of treating the foundation with liquid rubber is: 130 x 850 = 110,500 rubles.

Foundation preparation work

It is important to understand here that before laying waterproofing (any) the base must be prepared. It must be strong, smooth (fill shells, cavities, cut or knock down protruding stones, etc.) and clean. It is necessary to install fillets at the junctions. These aspects are described in detail in the Liquid Rubber Guide.

Most objects require foundation preparation. It will take time and additional labor. For small businesses, it is preferable for this stage of work to be carried out by others, but with mandatory acceptance of the foundation by you. If it comes to a construction company that has both hands and resources, then it is, of course, more profitable to take on this stage of work as well.

Here, for the business plan of a small business for the provision of liquid rubber services, work on preparing the foundation is not taken into account.

The advantage of doing business with liquid rubber is mobility and efficiency. On the appointed day, bring barrels of raw materials to the site on a truck, bring the installation, quickly turn around, complete the application in 2-3-4-5-6 hours, turn up, pick up the installation and leave.

It is imperative that before delivering barrels and equipment to the site, you should go out, inspect and make sure that everything is ready. If you say, “We have everything ready, come tomorrow,” you shouldn’t trust the customer.

Work on applying liquid rubber and related

If you have all the necessary equipment and devices, the minimum laying speed of liquid rubber is 120 m2 per hour, with a consumption of 4.3 kg/m2 of bitumen emulsion, which corresponds to a coating thickness of 3 mm.

However, it should be taken into account that there are always stops, breaks, etc. Therefore, for a real assessment of the time of direct application of liquid rubber, a correction factor should be used. When working on the horizon it is 0.7, and on walls - 0.5.

Therefore, directly spraying liquid rubber on 165 m2 of concrete will require 165 / 120 / 0.7 = 1.96 hours, i.e. 2 hours.

Therefore, directly spraying liquid rubber on 130 m2 of walls requires 130 / 120 / 0.5 = 2.17 hours, i.e. 2 hours and 10 minutes.

The time for deployment on site is on average 2 hours.

You need to unload the barrels and spread them around the perimeter. Then unload the installation. Solve the issue with the connection point if an electrical installation is used. In this regard, it should be noted that gasoline equipment is more convenient, because autonomous and does not depend on anything on site. In addition, the hoses (from the installation to the application site) can be up to 100 m, which allows work to be carried out from one point, without moving equipment and barrels.

The barrels with the emulsion should be opened. Prepare a solution of calcium chloride. The equipment must be reactivated, adjusted if necessary, and ensure that the coating will be obtained correctly.

In a word, if you can and understand everything, then in 2 hours you can prepare to start work.

Before performing a two-component application of liquid rubber, the insulated base must be primed. The emulsion itself is used as a primer, without an activator solution.

After completing the application of waterproofing, time is required for “curling”. It’s easier here: wash the hoses and pumps, preserve the installation, roll up the hoses, and, if necessary, pack them in film. Load the unit, tools, and work containers into the machine.

On average, it takes at least 1 hour to roll up on site.

We recommend that you discuss in advance with the Customer the issue of empty barrels that will remain after applying liquid rubber. In order not to spend money on a truck to remove them, agree in advance that the empty containers remain at the construction site.

Consumption of raw materials and other materials

The main cost item for a business applying seamless waterproofing is the liquid rubber itself, i.e. bitumen-polymer emulsion.

The consumption of liquid rubber is determined by the requirements (and wallet) of the customer. If you want to get a better quality (thicker) coating, you need more liquid per 1m2. Need something cheaper and no warranty requirements? You can reduce the consumption to 3kg/m2.

For this example, we assume that the consumption of liquid rubber is 4.3 kg/m2 to obtain a coating 3 mm thick. This is a good value. But, unfortunately, only 20% of companies in Russia operate this way.

For horizontal waterproofing of 165 m2, 165 x 4.3 = 709.5 kg is required. You should also take into account the consumption of the emulsion for priming the base. On average, 0.2 kg/m2, i.e. 33kg. Total, 742.5 kg. Practice shows that the calculated value should be increased by 5%. We get 780kg.

Powder consumption is, on average, 4 kg per barrel. Thus, in the first case, 16 kg of CaCl2 is required, and in the second - 12 kg.

Diesel fuel consumption

Another cost item is diesel fuel for flushing the installation. How the equipment is washed and preserved, how often it should be done, etc. - all this is described in detail in the technical data sheet supplied along with the installation.

The diesel fuel consumption rate is 40 liters with a hose length of 20 m. But these 40 liters are divided into “20 liters of clean” and “20 liters of dirty” diesel fuel. In fact, every 20 liters of diesel fuel are used twice: for a final rinse today and a rough (first) rinse tomorrow. Thus, the actual consumption of pure diesel fuel is 20 liters.

If you extend the pipelines from the pumps to the fishing rod, and for a gasoline installation the maximum extension is 80 m, then the diesel fuel consumption rate increases. Every 20 m of hose extension requires an additional 20 liters of flushing fluid. For example, if the length of the hoses is 60 m, then 40+20+20 diesel fuel is required, i.e. 80l, of which 40l is “dirty” and 40l is clean solarium.

For the problem under consideration, we will assume that the hoses were not extended, i.e. The basic delivery set is used, where from the pump to the fishing rod is 20m.

Transport costs and more

Transportation costs should also be included in the cost. For our example, 4 barrels should be delivered to the construction site the first time, and three barrels the second time. The best option is Gazelle, which you will need to hire.

In the case of Moscow and the Moscow region, the price consists of an hourly payment and payment for each km of mileage from the Moscow Ring Road in the region. For example, in the summer of 2014, the tariffs were as follows:

- Cost of 1 hour = 400 rub.

- Cost of 1 km from the Moscow Ring Road = 12 rubles.

If you need to deliver barrels to Klin (95 km from the Moscow Ring Road along Leningradskoye Shosse), this will take approximately 4 hours, because the starting point is in the south of Moscow, at the intersection of the Moscow Ring Road and Kashirskoye Shosse, where the main Technoprok warehouse is located.

Total expenses will be 400x4 + 95x12 = 1600 + 1140 = 2740 rubles.

In other regions of Russia, prices may be different, but, on average for the country, for this section of transport costs you should plan 3,000 rubles.

Transportation costs should also include the cost of gasoline, which will be spent to get to the site in your car. You will need to come at least three times:

- For the first time, to inspect the property, agree on a price and explain what and how to prepare before applying waterproofing.

- A second time, to make sure that the base is ready for applying liquid rubber (you shouldn’t take your word for it, just a personal visual and organoleptic inspection).

- For the third time, to arrive together with an installation for applying liquid rubber (barrels, as a rule, travel separately by a hired Gazelle).

On average, the cost of fuel for your car per object is 2,000 rubles.

Unforeseen expenses may also arise: paying someone, buying something, etc. Contingency fund RUB 5,000.

Financial plan

The amount of starting capital includes:

- official registration – 20 thousand rubles;

- rental of premises - from 20 thousand rubles. and higher (depending on many factors);

- organizing an advertising campaign – 35 thousand rubles;

- wages to employees - 35 thousand rubles, including 20 thousand rubles. – operator, 15 thousand rubles. - assistant. Also, this expense item may be zero if the entrepreneur himself goes out to fulfill orders;

- purchase of necessary equipment – 140 thousand rubles;

- purchase of raw materials – 100 thousand rubles;

- purchase of personal protective equipment – 15 thousand rubles;

- outsourcing – 5 thousand rubles.

Total: 370 thousand rubles. – the amount of one-time costs and 55 thousand rubles. – monthly.

Reducing costs can be achieved by reducing staff and purchasing fewer raw materials. You can save no less significantly if you organize storage of equipment and material on your own territory, rather than in rented premises.

In addition, it is necessary to resolve the issue regarding delivery to large objects, because liquid rubber in large volumes weighs a lot. In this case, you should think about purchasing a small truck into which you can load several hundredweight of raw materials. And to transport the equipment itself, you need at least a passenger car. Therefore, it should be about 300 thousand rubles. include in the estimate for the purchase of a used car, in which it will be possible to transport not only people, but also consumables.

Material

What do you need to paint a car? The basis is liquid rubber Plasti Dip - a multifunctional synthetic coating, which is characterized by high strength and resistance to external factors. It does not contain silicone, is odorless and remains elastic after complete drying. Many people are concerned about how much liquid rubber is needed to completely cover a car. On average, from 5 to 12 liters of this substance need to be applied to the car (depending on its size). One 5-liter jar of Plasti Dip costs approximately 5,700 rubles. If you get into business seriously, you can buy material at a wholesale price.

Organizational plan

The start of any business begins with registration as a business entity. This type of activity allows you to register as an individual entrepreneur, since waterproofing is part of the non-capital construction category.

There is also no need to obtain a work license or join a self-regulatory organization. But cooperation with the construction trade union is still desirable, as this allows you to count on receiving large orders and has a positive effect on the promotion of the new service.

Seamless sprayed waterproofing is a very simple procedure, but some theoretical knowledge is still necessary. The ideal option is when the entrepreneur has experience working in construction. In this case, mastering the unit required for spraying is faster and easier. If you don’t have the knowledge and experience, then you definitely need to practice a little before going to your first client and master the technology.

Liquid rubber can be applied to many surfaces - from the foundation to the roof, while any angle of inclination is allowed (it can even be a vertical wall), the coating also does not matter.

This is interesting: Raising the retirement age of police officers

If we consider large-scale construction, we can say that such a membrane is used to cover a wide variety of floors, flooded rooms, roofs and, in general, any surfaces that come into contact with any liquid . And if we talk about private home ownership, then its most relevant use is the protection of an artificial reservoir or swimming pool.

For the first stage of work, when there are not many orders yet, one person will be enough, and over time, when there are more clients, it is better to hire the appropriate number of employees, since waiting too long can scare away the customer.

If you are interested in how to open a hair salon in a small town, read this material.

How to start a plastic bottle recycling business - see here.

Range of applications for new generation waterproofing

This material is successfully used to protect against moisture in construction, in the preparation of foundations, walls, pipelines and roofing work. In addition, liquid rubber is widely used for sealing road objects, outbuildings and underground premises.

The main advantage of this material is its resistance to periodic physical stress and vibration, and if destroyed, it is restored quite quickly and easily. That is why it is widely used for sealing roofs with chimney shafts, swimming pools and wells, as well as garages, basements and basements.

In addition, liquid rubber provides reliable protection for absolutely any building materials (wood, metal, etc.).

This material is quite fluid, which allows you to reliably seal all cracks and possible crevices in structures. Repeating the surface relief, the emulsion is able to penetrate the material, thereby forming a reliable and durable protective layer with a thickness of about 4 millimeters. Thus, a kind of protective coating with excellent adhesion is created, which leaves no chance for moisture penetration.

This is a huge advantage in pool sealing and roofing applications.

The results of technological tests showed that just one protective layer of liquid rubber can completely replace several layers of built-up waterproofing.

Marketing plan

For this type of business, the best marketing ploy is “live advertising,” that is, when one satisfied customer tells his friends about how well his order was completed. Of course, no one cares about the use of other types of advertising either - the most effective way to convey information to the target audience.

The construction of the entire marketing campaign should be based on the advantages of this type of waterproofing. It is recommended to distribute leaflets through various construction stores and post information about the material on the appropriate Internet portal and in thematic groups on social networks.

Creating a business card website is only advisable if you plan to open a business in a big city.

Risk analysis

The full production cycle begins with the delivery of raw materials, continues with the intended use of equipment and ends with the sale of the final product. In this case, the following risks may occur:

- Late delivery of raw materials . The likelihood of this situation occurring can be minimized by signing long-term contracts with reliable (long-established in the market) suppliers.

- Technological failures with equipment . Possible troubles can be avoided by following the supplied operating instructions and timely maintenance.

- Unprofessional work of a hired employee, transfer of a trade secret to a competitor and other intra-company risks.

One or another number of risks is inherent in any business activity, and the development of a number of preventive measures allows not only to prepare for their occurrence, but also to completely eliminate them.

No. 1. What is liquid rubber?

Liquid rubber has recently appeared on the waterproofing materials market, so not many people know what this coating is made from. Let's start with the fact that the material has nothing in common with ordinary rubber. If the rubber we all know is made from rubber, then liquid rubber is a product of bitumen processing. Latex and other modifying additives, stabilizers, polymers and water are added to it. The result is a two-component system, an emulsion, the properties of which allow it to be used for high-quality waterproofing. What it has in common with regular rubber is only its black color and the ability to self-heal after minor damage, punctures, or deformations—in this regard, the material outperforms all traditional roll analogues.

It would be more correct to call the material sprayed seamless waterproofing , but this name has not caught on among buyers, apparently due to excessive complexity. Many manufacturers insist on the same name, but the concept of liquid rubber continues to be used in the domestic market. By the way, they tried to produce something similar in the USSR in the 70s, but the quality of the bitumen raw materials was low, so the material did not become widespread.

Liquid rubber does not allow water to pass through at all, which is largely ensured by the complete absence of seams. That is why the material is actively used in waterproofing foundations, roofs, swimming pools, basements, ponds, bridges, as well as for anti-corrosion treatment.